Reinforced earth retaining walls: specific products for each function

The function of retaining wall structures is to retain and reinforce soil faces. They can be built in a multitude of areas, including private ones such as gardens and vineyards, as well as public areas such as roads, railways and embankments.

They meet the need to recover usable spaces as they can also be built with a steeply sloping face.

The authentic green appearance

Nowadays, the modern building industry is highly aware of sustainability and territorial integration. Under certain conditions, reinforced earth retaining walls can replace conventional concrete walls, without underestimating the aesthetic appearance of the landscape. This is even more important in areas subject to landscape restrictions that require the preservation of natural aspects using specific materials and construction techniques.

TeMa Building solutions integrate these trends by catering to various problems concerning land conformation and hydrogeological protection.

The functions of reinforced earth retaining walls and the products required to achieve them

Slope gradient, exposure to weather conditions (including severe ones) and the mechanical properties of the terrain often require technical solutions that stabilise a slope. Synthetic products can be used, each one performing a specific function.

Reinforcement with geogrids

The compressive strength of the soil is combined with the tensile strength of the geosynthetic product (such as T-Grid). The friction involved develops a tensional state that stabilises the structure.

Profiling with formwork units

Electro-welded metal structures such as formwork units provide a shaping of the soil face up to a 65° slope.

Controlling surface erosion with erosion control mats

Severe or prolonged weather conditions, such as strong winds and sudden downpours – and the resulting surface run-off of water – could lead to erosion and depletion at the face of reinforced earth layers, particularly if they are fully greened. The solution to this problem is to use, on the face of each layer, three-dimensional synthetic mats such as T-Mat made of polypropylene or K-Mat FG Green made of fibreglass. Alternatively, natural, biodegradable mats made of jute fibre such as T-Juta 500 can be used (also available in an XLversion).

Soil containment using gabions

An alternative solution to reinforced earth walls can be found in walls built using double-twisted wire mesh gabions, such as T-Gabion, filled with pebbles. Gabions are also an interesting solution for smaller residential projects: they provide containment while offering a different and innovative aesthetic appearance.

- Published in BUILDING, Retaining walls, Retaining walls elements

Ballasted roofs: why gravel, and how to protect their waterproofing

Something of an innovation in the Italian building scene, while also being a useful device for protecting the roof, the ballasted flat roof is a solution that can become a distinctive feature of either a residential or commercial building.

Unlike the traditional system involving the use of concrete, using gravel is an option that brings a number of attractive advantages:

- it protects the roof against wind and UV rays

- it protects the roof against mechanical damage

- it is low maintenance

- it provides thermal comfort in summer as it shades the roof

- it makes the whole roof system practically fireproof

- it is long lasting.

In building, the choice of a ballasted roof is often prompted by aesthetic reasons for a holiday home or a hotel by the sea, or in an area with high sunshine hours… while it also caters to the need for optimal insulation and low maintenance.

The TeMa Building Solutions answer for protecting ballasted roofs

When gravel is laid, the load can tear the waterproofing layer on the roof underneath, and this comes with the risk of leaks, with all the ensuing stain, mould and structural damage issues.

So it is important to address the need for rainwater drainage and mechanical protection of the waterproofing.

TeMa Building Solutions has come up with a product that serves multiple functions: the product in question is T-Kone G Drain, the studded membrane (which serves to protect the waterproofing) featuring a geotextile (addressing the need for filtration and separation).

Placed between the gravel layer and waterproofing, T-Kone G-Drain is thin, strong and ideal for an effective build-up without the bulk.

- Published in Ballasted roofs, BUILDING, Studded membranes and accessories

Green surfaces and green roofs: benefits and technical ins and outs

In recent years, “green” has become more and more of a buzzword, encompassing simple and cost-effective solutions that can be adopted by anyone with a roof. We’re talking green roofs, which, in addition to bringing undeniable environmental benefits, are the perfect place for relaxing with the family or enjoying summer drinks with friends. The origins of roof gardens date back to ancient times — think Hanging Gardens of Babylon — and, today, are built for extreme reliability, including long service life, with excellent products producing even more advantages.

Let’s take a look at the full picture in detail.

The advantages of green areas

For the environment

Plants and grass are natural carbon sinks, absorbing CO2 and releasing oxygen, in addition to filtering particulate matter. In addition, they lessen the urban microclimate effect by lowering temperatures by several degrees centigrade, and reduce electrosmog caused by any electronic device.

They muffle noise and, if designed well, absorb and retain the early sudden downpours associated with significant rain events.

A series of sustainable improvements for urban wellbeing, improving air quality with less smog and particulate matter.

For occupant comfort

Vegetation also acts as natural thermal insulation — which is no small advantage given the energy crises of recent months — and soundproofing in loft bedrooms. Furthermore, it provides the roof with effective protection against UV rays, mechanical stress and daily variations in temperature, thus increasing the average service life of waterproofing.

Lastly, creating a garden on a roof increases the value of the property.

From a technical point of view

A green roof build-up comprises a number of layers, including geosynthetics offering better performance than traditional systems in terms of drainage, mechanical protection of waterproofing, and filtration. The products used are lighter and non-bulky, easy to transport and quick to install.

Functions required of the roof

There are 4 main functions involved:

- Reservoir (to hold rainwater for irrigation purposes until it is needed) and drainage (to remove excess water). This combined function is addressed with 20mm HDPE studded membranes T-Kone H XL and T-Kone H XL S.

- Control of surface erosion caused by atmospheric agents. This function is addressed with natural fibre matting T-Juta 500 and the synthetic geomat T-Mat.

- Drainage. This is where T-Mix Drain 20 SS comes in, the cuspated-fibre geomat sandwiched between 2 geotextiles.

- Mechanical protection of waterproofing. The geotextiles from the Tematex NW PET range, in white and black, fit the bill.

- Published in BUILDING, Flat green roofs

Tips for the correct laying of TMD 1011

For vertical applications, such as foundation walls, and for horizontal applications, such as flat roofs, mechanical protection of waterproofing is required and, often, also drainage: TMD 1011 is a studded membrane, produced by TeMa Building Solutions, that performs both functions: drainage for vertical applications and waterproofing protection for horizontal applications.

A few tips for laying TMD 1011 on horizontal surfaces

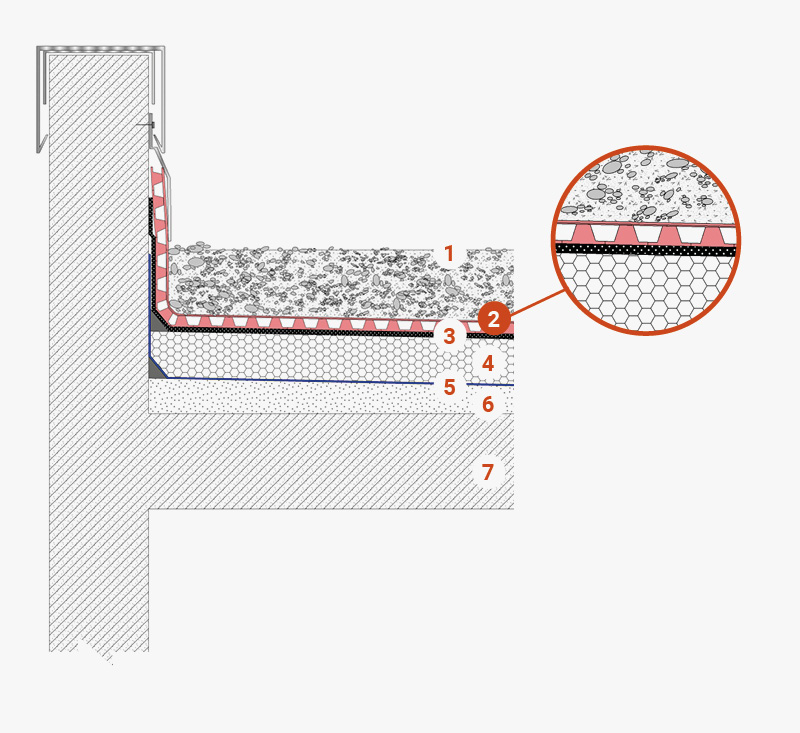

Flat roof with gravel finish (weighted)

1 Gravel finish

2 TMD 1011 membrane serving as a drainage layer and for waterproofing protection

3 Waterproofing membrane

4 Thermal and acoustic insulation

5 Vapour barrier

6 Sloping underlayment

7 Load-bearing structure

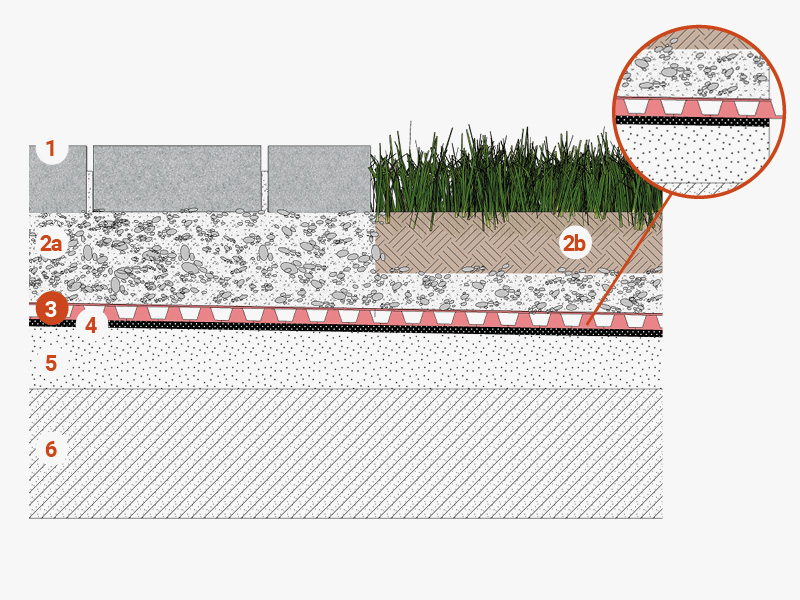

Walkways and green areas

Walkways and green areas

1 Interlocking block paving

2a Crushed stone bedding course

2b Growing medium

3 TMD 1011 membrane serving as a drainage layer and for waterproofing protection

4 Waterproofing membrane

5 Vapour barrier

6 Sloping underlayment

7 Load-bearing structure

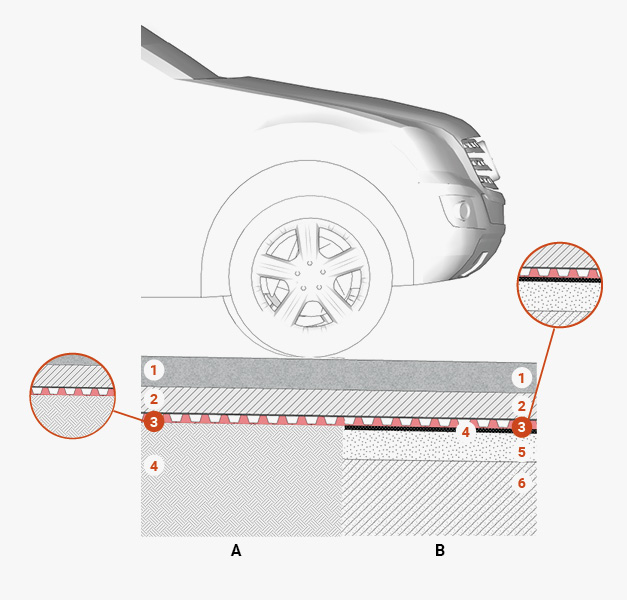

Surfaces suitable for vehicle traffic A

1 Paving designed to take vehicle loads

2 Sand bedding layer

3 TMD 1011 membrane serving as a:

– drainage layer

– substrate in place of traditional concrete levelling compounds

– separating and leachate containment layer (oils or hydrocarbons)

4 Substructure / ground

Surfaces suitable for vehicle traffic B

1 Paving designed to take vehicle loads

2 Sand bedding layer

3 TMD 1011 membrane serving as a drainage layer and for waterproofing protection

4 Waterproofing membrane

5 Sloping underlayment

6 Load-bearing structure

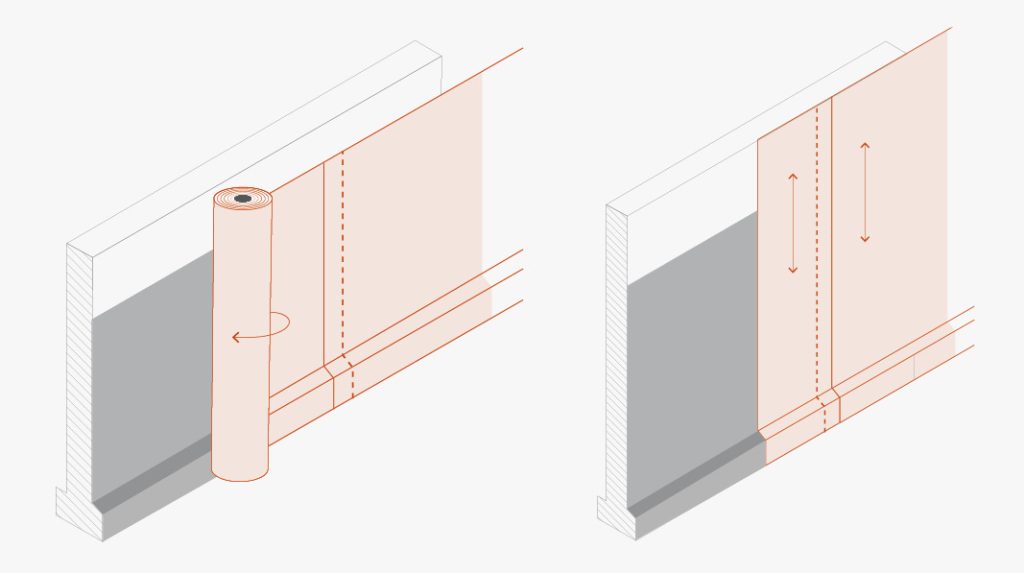

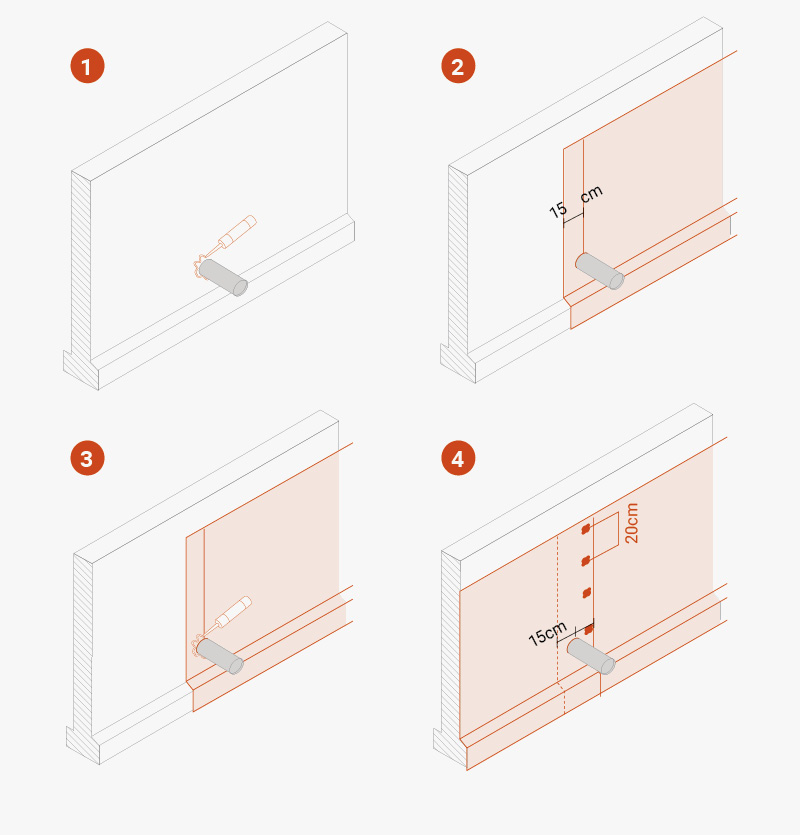

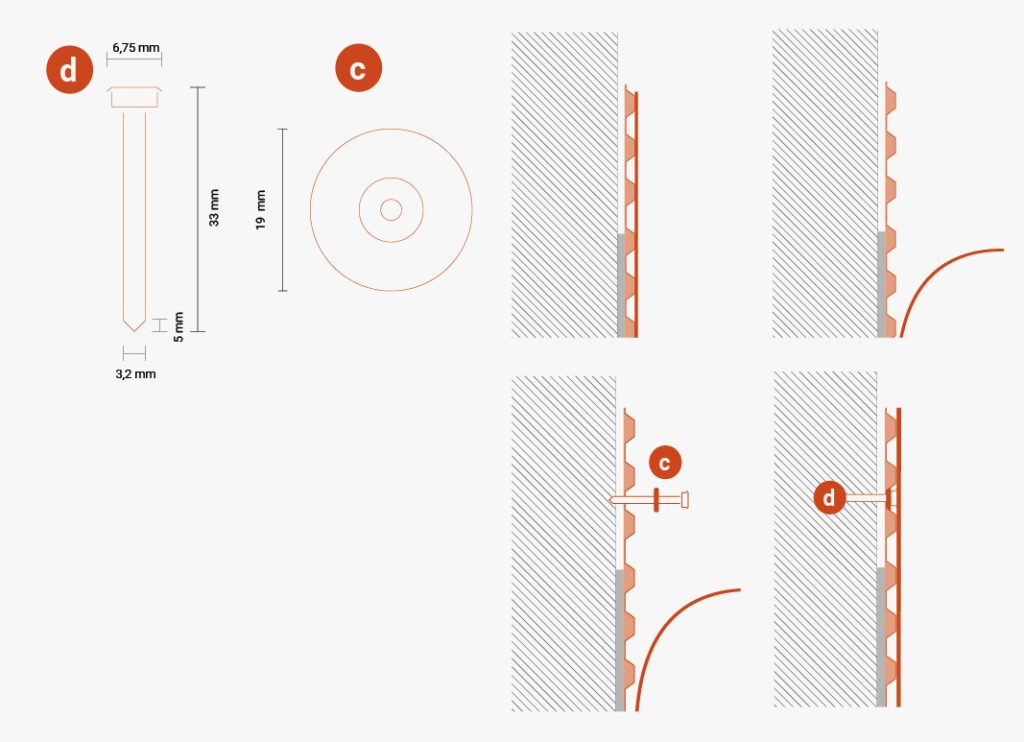

A few tips for laying TMD 1011 on vertical surfaces

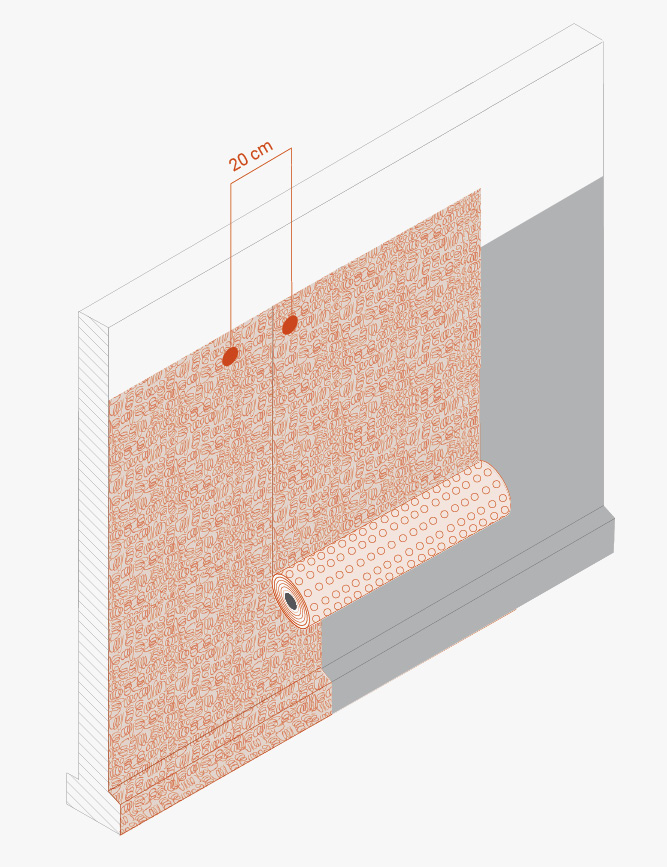

Unroll the membrane and install it vertically or horizontally: in the latter case, the width of the roll corresponds to the height of the wall to be protected. Two consecutive membranes should overlap by about 20 cm, and the studs should interlock.

For horizontal joints, if the TMD 1011 membrane is not wide enough to completely cover the height of the installation, the first layer should be installed from the base upwards and then, keeping an overlap of at least 15 cm, the second layer should be installed by overlapping the first layer outwards (i.e. towards the side away from the wall). Install washers every 20 cm in the overlapping area.

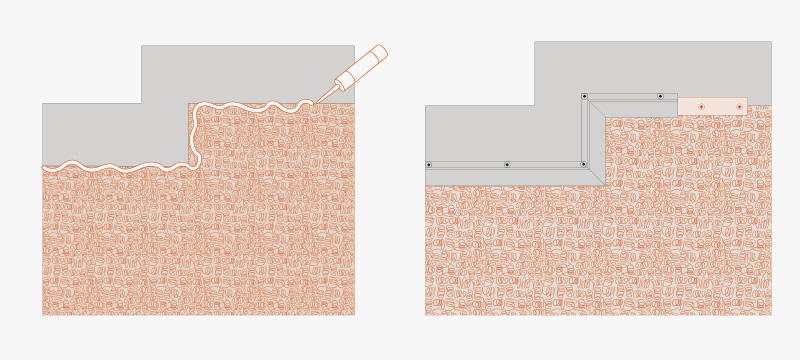

Inlets for utility connections, such as water, gas, sewers or similar pipelines

- Place mastic sealant around the pipeline or inlet.

- Cut the TMD 1011 membrane vertically so that it extends 15 cm beyond the pipeline or inlet, trimming the membrane so that it adheres as tightly as possible.

- Put mastic sealant on the membrane so that there is a layer of mastic both above and below the membrane around the pipeline or inlet.

- Start the next installation of the membrane 15 cm before the pipeline or inlet so that the overlap around the pipeline or inlet is 30 cm. Trim again around the pipeline or inlet for watertightness.

- Install fasteners every 20 cm along the edge of the overlapping membrane.

Change of level or areas where the smooth part has been trimmed

Use T-Profile + T-Nails to seal the edge, using a sealant for the area to ensure that the edge is properly sealed.

TMD 1011 should also be protected with T-Profile to prevent soil from penetrating into the gap between the wall and membrane. Then, fasten it using washers and nails with T-Nails spaced at intervals of 20-30 cm, either along the upper edge of the studded membrane or along the profile.

Drainage for diaphragms and berlin walls: a practical and safe solution

Some of the most widely used works in the civil engineering field are diaphragms and berlin walls, which counteract strong thrusts of the soil and prevent landslides and structural subsidence.

Diaphragms are supporting walls consisting of pointed vertical elements (piles) or continuous elements (walls) made of steel or reinforced concrete. They are driven into the ground to a considerable depth, whereas Berlin walls are flexible retaining structures constructed with vertical micro-piles.

Both solutions are used where it’s impossible to construct excavation walls of an adequate gradient due to the presence of other nearby structures and to the morphology of the area , which imposes limited work spaces (that would make manoeuvring large machinery impossible).

Berlin walls made of micro-piles are one of the most popular applications on construction sites for implementing waterproof retaining works. The technique allows work to be carried out on almost all types of terrain, especially when it’s necessary to use on-site systems that are smaller than in the past.

Since works are in contact with the ground, the drainage aspect should not be underestimated. If rainwater and groundwater exert pressure on the vertical wall, they may damage the waterproofing. TeMa Building Solutions therefore has the right product for this application: T-Mix Drain WP, the geocomposite that not only drains but also provides the functions of filtration, separation and stay-in-place formwork.

TeMa has acquired considerable experience with geocomposites. For many years, the company has been providing this system to replace the conventional gravel drainage system. The results are long-lasting and it’s the ideal solution: compared to conventional gravel, it’s less bulky, easily transported and quick to install. This reduces the costs of transport and implementation and on-site construction time while, last but not least, resulting in considerable savings in terms of CO2.

Fields of application

As mentioned above, diaphragms and berlin walls are widely used where space is limited. More specifically, they can be used in the construction industry, for example for underground garages in homes or commercial premises, for basements. They can also be used in river works, such as quays and piers for boats, or in earth dams and wells.

Having the experience of TeMa technicians and tested effective products such as T-Mix Drain WP at your disposal is therefore a guarantee for your construction site.

Waterproofing when concrete casting

Concrete casting involves creating a new concrete element as a continuation of an already existing one. Most often it’s impossible to create a monolithic block with a single casting: consider, for example, very large structures or the connection between vertical and horizontal walls. With concrete casting you can obtain monolithic structures with their own characteristics, built in stages at subsequent times. So, you proceed with small blocks and join each casting to the previous one, creating a monolith piece by piece.

Structural connection is achieved by using reinforcing irons, taking special care with drilling the existing block and the length of anchorage. While ensuring attachment to the sequence of blocks, reinforcing irons are potential lines for water seepage. We well know that accumulation of moisture in walls may have very severe consequences: structural fragility and very unhealthy stains and moulds.

An effective solution is to insert bentonite kerbs which waterproof any voids that may have formed at the base of walls or in contact with reinforcing irons. The intrinsic property of sodium bentonite is exploited, which is the ability to swell on contact with water, filling the available space and forming an impermeable compound.

Furthermore, this material provides high resistance to hydraulic load, is easily applied and adheres perfectly to the support.

The range of building products from TeMa Building Solutions also includes T-Bentostop, the waterstop made of hydro-expanding bentonite for waterproofing and sealing concrete casting.

Concrete industrial paving: How to ensure versatility and durability

A factory layout determines the physical positioning of machines, workstations that develop individual processes and service departments in order to make the work of people, machines and materials more efficient.

Paving is subjected to continuous stress and have to withstand considerable loads. Concrete has its own characteristics to meet these needs and is also very aesthetically versatile, which means that it’s often used by designers in domestic and commercial contexts, both indoors and outdoors. Moreover, it can be quickly customised with textures or other types of printing.

What functions are important in industrial contexts?

Industrial paving inevitably suffers wear and tear from prolonged and intensive use.

It is therefore necessary to guarantee high compressive strength. This is because the surfaces of environments such as warehouses and industrial facilities are constantly subject to heavy loads: storage shelving systems, machinery and moving vehicles such as pallet stackers and forklift trucks. In many cases, weights are concentrated more in some places than in others (e.g. the areas where pallet stackers move or the quintals of goods in the warehouse that weigh down on the same spot for a long time).

This can also cause fissures and cracks on the surface that would hinder access and make it difficult to carry out normal work activities.

Lastly, as already mentioned, concrete is a very versatile material that can be laid over other types of substrate and also customised as required.

How to achieve an optimum and long-lasting result?

Thorough planning from the outset and the choice of suitable materials is the first step to a successful result, but painstaking attention during laying is also important.

The product range from TeMa Building Solutions includes specific products for the reinforcement of this type of paving. T-Fiberglas CLS mesh, made of fiberglass and coated with a special alkaline dressing, is designed to reinforce horizontal concrete applications, whereas T-Zink Net is the anti-cracking mesh made of galvanised steel.

- Published in BUILDING, Concrete paving

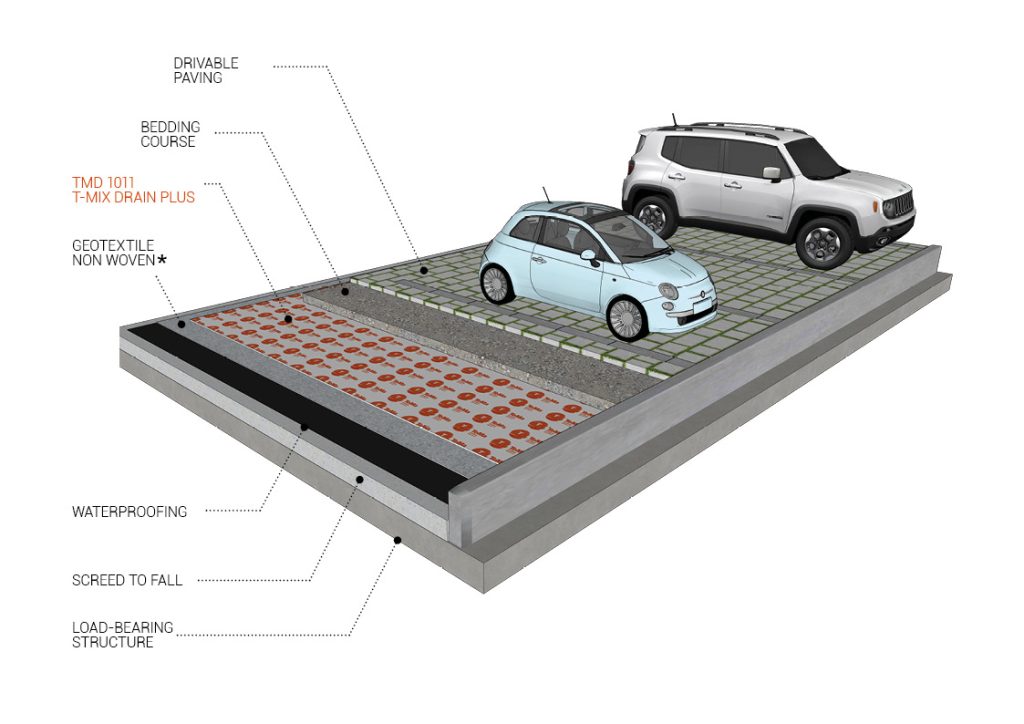

Rooftop car park: next-level solution for making the most of underused space.

City centres are overcrowded with vehicles and restricted areas, car parks are “stressed” and there are never enough spaces to go round. Alongside the more “standard” trafficable ceiling slab solutions — such as in the case of underground garages — it’s not too much of a stretch, where structurally feasible, to think about designing or making better use of spaces on elevated levels.

Over the holidays, car parks on the roofs of public buildings or buildings for use by the public could also provide refuge for the cars of passers-through. During the offices’ closing time, for example, these parking spaces can become a real asset, an ideal solution for making use of otherwise unused space and increasing the number of car parks for people travelling to tourist hot spots

Continual vehicular traffic and exposure to the elements — from freezing temperatures to sweltering heat — mean the construction materials used must be fit for purpose. Intensive use means it’s imperative all the proper layers are in place (build-up design) to serve the different specific functions. Let’s see what these layers are.

What do we need to be careful about when designing a rooftop car park?

This kind of roof is subjected to high loads, both static and dynamic, from vehicles of all kinds. This makes the mechanical protection of the waterproofing layer and the need for high compressive strength two key focus areas.

Drainage is another aspect to be factored into the design. Rainwater can seep into the underlying layers and damage them, so we need to ensure that water is drained off the roof properly.

We recommend applying studded membranes laminated with nonwovens or drainage geocomposites made from monofilaments or geonets.

Our drainage geocomposite T-Mix Drain Plus is a good candidate for the drainage layer. Alternatively, you can opt for the T-Net Drain 5 and T-Net Drain 7 geonets, which are sandwiched between nonwovens.

The job of mechanical protection, together with drainage, can instead be handled by the drainage geocomposite TMD 1011. The product consists of a filter geotextile laminated to a studded membrane, whose conformation delivers effective drainage even under the strain of high loads (up to 400 kPa).

- Published in BUILDING, Drainage geocomposites

- 1

- 2