TeMa, laser focus on the future for 30 (+1) years

TeMa Technologies and Materials has just celebrated thirty years in business. A spin-off of Tegola Canadese, it was actually established in 1993 with the aim of expanding its presence into the commercial, civil and geotechnical construction space. Focused on products and systems to protect building foundations from rainwater and groundwater, the company went on to gain impressive international experience, becoming a go-to provider for the making safe of landfills, handling of contaminated sites, and soil reinforcement systems with solutions designed to be increasingly resilient, even in the face of extreme weather events.

TeMa is headquartered in Italy and is present on four continents with facilities in Italy, the US, South Africa, Spain, Turkey, India, Romania and Russia. Our sales are projected to reach the 100 million euros mark, demonstrating significant growth, doubling our 2021 revenues. A 100% increase within the space of just four years.

Rapidity, speed and reliability are the cornerstones of our relationship with the market, qualities that are paired with innovation, development of human resources and a strong environmental commitment. This sense of environmental responsibility is linked to the fact that our main manufacturing facility is located in an industrial area in Vittorio Veneto set between the unspoilt forests of the Cansiglio plateau and the hills recognized as a UNESCO World Heritage site. A heartfelt respect for the region that we’ve proudly professed from day one of our industrial journey.

This is why, for TeMa, sustainability is about much more than just green claims: we recover quality plastics through two recycling plants for the reuse of polypropylene and high-density polyethylene, one in Russia and one in Romania. All waste materials are sorted and put through grinding, washing and filtering cycles, before being extruded and used to make new products.

Over our 30 (+1) years in business, TeMa has risen to the sustainability challenge with a growing awareness of the importance of this issue, coming up with environmentally friendly solutions for geotechnical applications. One notable example is our range of products for the construction of “reinforced soil retaining walls”, in addition to our specialist area: the development of innovative and effective materials for use in embankments, road ditches, hillside terracing, landfills and contaminated sites. TeMa earth-retaining systems use the actual soil in place of traditional reinforced concrete products, encouraging vegetation growth and being undeniably better for the landscape. Our solutions include geonets, geomembranes and metal structures featuring different angles, designed to support the soil on their own and control rainwater. Many applications include the use of pre-seeded biodegradable matting.

With TeMa products, processes can now be employed that enable a considerable saving in terms of the CO2 emissions involved in handling materials. The resulting reduction in environmental impact is amazing! By doing away with the need for gravel and instead using the soil excavated on site, the energy used to transport materials is kept to a minimum. This approach means structures can be built to be impact resistant, withstanding even violent weather events, which there has certainly been no shortage of in recent years.

TeMa stands as a bastion of modernity in the industry, forever trying out competitive technologies — in our laboratories — in order to come up with simple and efficient materials, products and systems. These solutions are underpinned by research, experimentation and testing: a team of professionals — men and women, engineers and technicians — who all bring their individual area of expertise to the table and are driven by a commitment to customer outcomes, offering support, assistance and an attentive ear.

While ESG (Environmental, Social, Governance) factors are only now becoming mainstream among many businesses, these issues have always been at the very core of TeMa’s corporate philosophy. TeMa products have helped save thousands of loads of aggregate from being quarried and transported over the last thirty-plus years, which has had an extremely positive impact on the environment.

- Published in CORPORATION, Research and development, TeMa Technologies and Materials

TeMa Technologies and Materials’ sustainable choice

We started out almost 30 years ago and being environmentally responsible has always been part of our philosophy, partly due to the fact that our headquarters are located less than three kilometres from the core zone of the hills recognized as a UNESCO World Heritage Site, and just over 6 km from the edge of the Cansiglio forest.

So protecting the environment was always going to be one of our key commitments, not just in our manufacturing systems, but also in the innovations implemented in the solutions we offer our customers.

Reinforced soil and CO2 savings

Our engineers have redesigned the reinforced soil system, leveraging the very pressure of the soil retained by geogrids, so as to save millions of cubic metres of concrete and aggregate, which would otherwise have to be carried to the site in hundreds of truckloads. Now it takes just one: a considerable saving in terms of CO2 in line with the goal of reducing the carbon footprint, which is the total amount of greenhouse gas emissions generated by a product or a process.

Our geonets and geogrids are made partly from recycled plastic sourced from facilities that are controlled to ensure the resulting plastic meets our standards. A substantial difference in terms of both the collection of material to be recycled and conditioned, and the recycling procedure itself (the material in question is high-density polyethylene, and polypropylene, which comes from bottles, containers, capsules and so on), as well as its preparation, for which – in order to ensure quality – we have set up two plants: EcoTeMa in Russia and Replastica in Romania.

A sustainability journey that TeMa has embarked on and is committed to pursuing further, continuing to invest in technologies and systems with a view to achieving zero emissions by 2050.

Our recycling production process

Material sorting: only materials that meet preset standards in terms of quality and type make it to the next stage. The sorted material is first shredded and then washed, then shredded and washed again. Only then does it qualify as a “raw material” ready to be turned into granules and then extruded and used in TeMa production processes.

It is supplied to our facilities across the Group for them to make into products to be introduced into the market in line with the specifications laid out by designers and in compliance with the legal requirements in the individual countries.

Where does the washing water end up?

The water used for washing is also reused once suitably treated. The portion of water not used is disposed of in compliance with specific government standards on environmental impact.

Renewable energy

Along with plastic recycling and a focus on reducing the amount of carbon dioxide released into the atmosphere, the IWIS Group has installed 3 photovoltaic systems of its own – with rated outputs of 200 kWp, 150 kWp and 100 kWp – as well as a cogenerator, together producing 50% of the energy used in manufacturing.

If you wish to receive information about it, CONTACT US.

- Published in CORPORATION, Research and development, TeMa Technologies and Materials

Environmental intervention works in keeping with our philosophy

An environmental reappraisal

Over the centuries the relationship between man and the environment has undergone considerable tensions. Rural development and the impetus in building have undoubtedly disrupted certain landscapes, reducing natural spaces to accommodate new urban and agricultural areas. This type of intervention work has led to a crisis in the ecosystem, imposing re-evaluation of the fragile balance between the economy and the environment.

This is the socio-cultural background that has led to global re-assessment aimed at defining programmes and new territorial management formulas. It has been the driving force behind TeMa Geo Solutions, the TeMa business unit dedicated to environmental intervention works. These are aimed at protecting land and offering the opportunity to operate using eco-compatible solutions and products that integrate into the environment without compromising its appearance or safety.

Sustainable development according to TeMa

Nestled at the foot of the hills declared a UNESCO World Heritage Site, the TeMa headquarters could not help but consistently correspond to this desire for sustainability, widespread in this area for some years now. But how has it contributed? By using raw materials responsibly, with 100% natural solutions and intervention procedures with low environmental impact.

Natural products

As a concrete example, TeMa addresses the problem of surface erosion of the soil by meteoric rain with Ecovernet® in natural fibres such as jute or Ecovermat® in natural fibres such as straw and coconut – or in biodegradable cellulose fibre. Installing products in this range allows intervention works to be carried out immediately, even in situations with difficult access for on-site vehicles. For such types of intervention works, total integration with the soil is achieved, guaranteeing lasting results over time.

Green intervention works

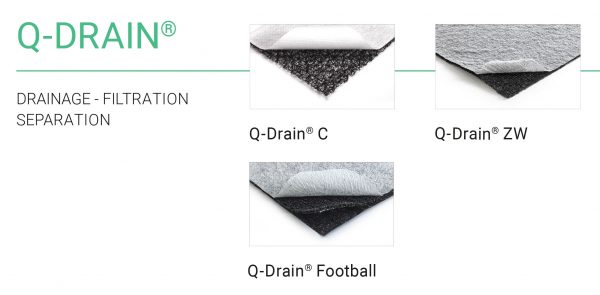

An interesting new development introduced by our technicians is the use of lightweight materials that feature reduced encumbrance, which not only affects the cost of the work but also speeds up the time required on-site. When building drainage systems, for example, TeMa does not rely on that range of inert materials from quarries that need to be extracted and transported. The company uses drainage geocomposites instead, such as Q-Drain, thus avoiding any waste of energy and CO₂ emissions into the air, thus ensuring quick installation.

These are just a few examples to show the potential that the field of environmental engineering has to offer:

- Reduction in costs while maintaining the effectiveness of intervention works

- Sustainability of the actions taken

- Protection and safeguarding of the soil

- Promotion of natural raw materials

To fully understand our philosophy, browse through the new catalogue dedicated to the protection of vineyards, which are the natural and cultural heritage of our lands and an identifying feature of our history. Inside it, you will find products and solutions for responsible and eco-compatible actions.

- Published in Drainage geocomposites and membranes, Erosion mats, GEO, Research and development