Controlling surface erosion with biomats and geomats

Soil erosion is an almost inevitable natural phenomenon that has become a greater concern in recent years due to the worsening climate situation – in Italy, for example, 132 extreme weather events were recorded between January and July 2022, a higher number than the annual average over the last decade – combined with long periods of drought.

Strong winds, heavy rain, hail and runoff tend to remove the surface layer of exposed soils, which often include organic matter and seeds. Climate change facilitates erosion, making it not only inevitable but also hazardous if left uncontrolled.

It’s essential to counter or mitigate the phenomenon: soil provides us with food, biomass and raw materials; human activities take place on it and it’s part of the landscape and our cultural heritage.

Which structures are more subject to surface erosion?

The areas of application most affected by the erosive action of the climate are:

- slopes and the sides of landfills and contaminated sites, and those that have been grassed for appreciable aesthetic improvement;

- reinforced earth structures, more specifically terracing in vineyards and the embankments of canals or rivers;

- ascending/descending ramps from flyovers, tunnel entrances and noise barriers on roads and railways;

- dry, rocky slopes, of all angles, that shape the terrain of Italy.

The effects of surface erosion

The uncontrolled removal of the surface topsoil and the failure of vegetation to take root results in ‘thinning’ of the soil and a risk to the stability of sloping areas.

What can be done to prevent surface erosion?

We should begin by pointing out that a case-by-case assessment is required that considers many variables, such as the nature and uniformity of the soil, the slope gradient, the type of slope (dry or rocky) and the weather conditions in the area where intervention work is to be carried out.

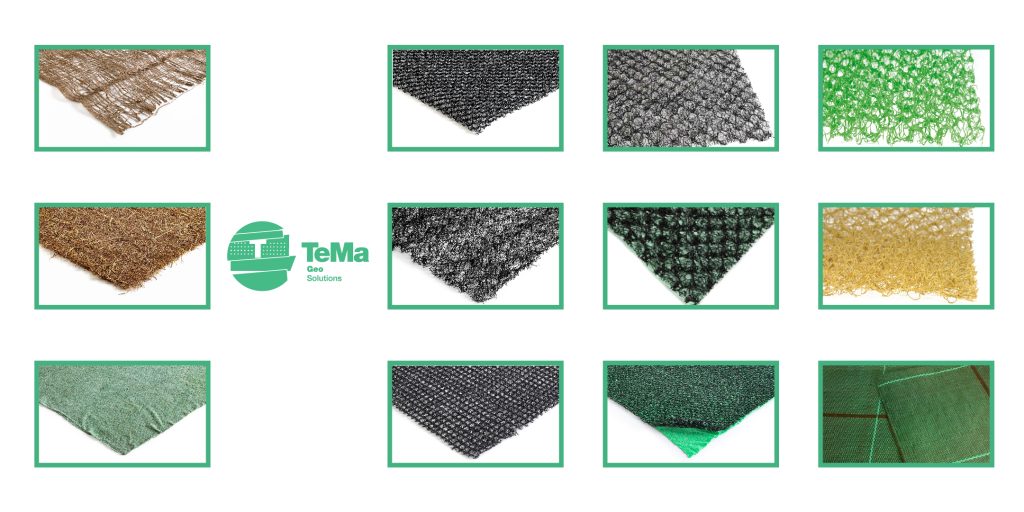

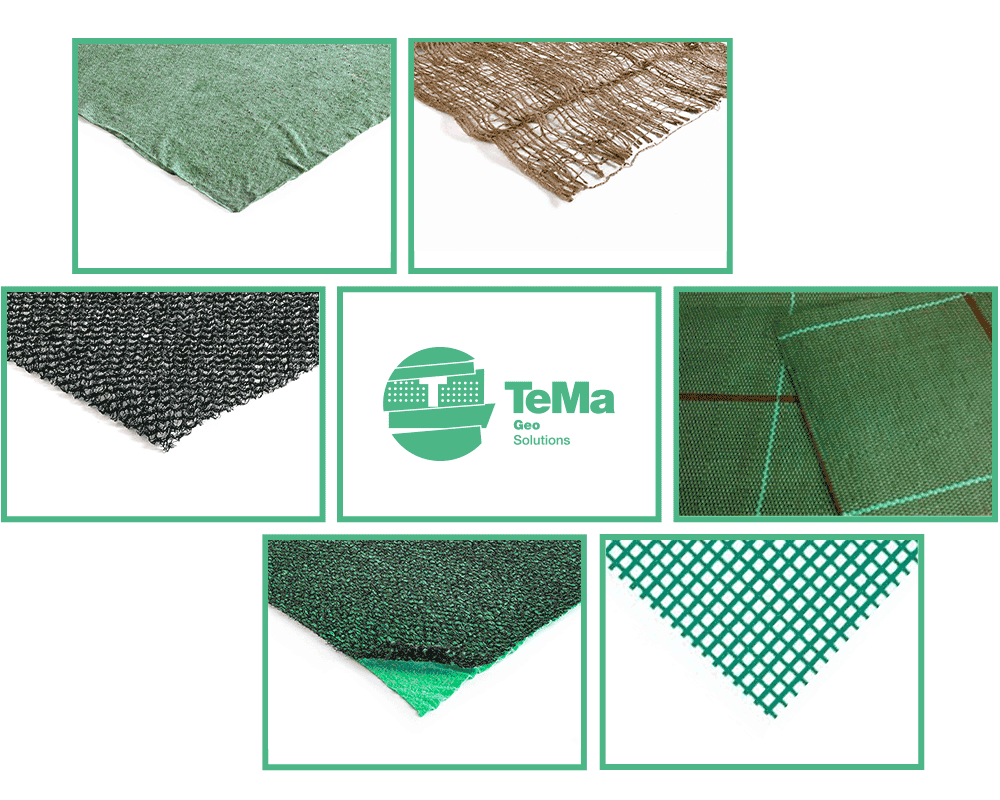

In general, vegetation, whatever type it is, has a natural ability to protect soils from erosion. So the best course of action is to quickly encourage grassing and then apply biodegradable mats made of jute, straw, coconut and cellulose fibre, which can also be pre-seeded.

TeMa Geo Solutions recommends biomats such as Ecovermat, Ecovermat P and PC, and Ecovernet.

Alternatively, or combined with these, synthetic geomats, mainly made of polymer monofilaments, can be used.

Once laid, they are covered with another layer of soil: in this way, the roots of growing vegetation will become entangled with the geomat, creating an almost permanent erosion protection system.

Once again, TeMa Geo Solutions offers a wide range of geomats to choose from.

Uncertain about what to choose? We can help you. CONTACT US!

- Published in Erosion mats, GEO, Landfills, Reinforced earth structures, Reinforced earth structures - Erosion control, Roads

Reinforced earth structures as noise barriers

Hearing the noise of traffic outside your window all day long is irritating and distracting and, in the long term, also harmful to your health.

This is why the WHO and a number of laws govern the use of noise remediation systems in cities: the Framework Law no. 447 of 1995 for Italy and the European Directive on Environmental Noise no. 49/2022. If the cause of the noise cannot be addressed, the solution is to install protective barriers. Various kinds can be used, but in this case we focus on reinforced earth structures that require specific measures, which we discuss here.

For example, the Pedemontana Veneta is a new toll motorway in Italy: nearly 100 km long. Almost entirely in operation in the north-east of the Veneto region, the main route of this motorway runs through a deep trench in order to minimise the ‘territorial’ and environmental impact on the surrounding area. This means that long sloping areas of reinforced earth can be found along the sides of the motorway, with rows of trees and hedges for 58.61 km and green areas covering 1,333,410 square metres of hedgerows, groves, grassy slopes and tree-lined meadows.

A focus on noise with much regard for the landscape.

What do reinforced earth noise barriers consist of?

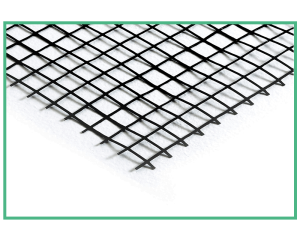

For this type of embankment with its typical trapezoidal shape, earth is used that will be covered by vegetation over time. Geosynthetic reinforcements and geogrids are added to support the earth, which already has good compressive strength. These are inserted horizontally into the ground and develop friction and tension that stabilise the structure, increasing its resistance to stress.

The TeMa Geo Solutions offer includes the X-Grid Pet PVC range of geogrids, with different resistance values, which are ideal for all kinds of contexts.

Another aspect to bear in mind is surface erosion of the soil: to counteract this, synthetic geomats are applied, also with a mulching function to encourage the growth of grass cover, or natural fibre bionets.

Also in this case, TeMa Geo Solutions offers a wide choice ranging from Ecovermat F Grass and Ecovernet FJ to the K-Mat range.

Why use a vegetation barrier as a protective noise barrier?

A vegetation barrier has an unquestionable ability to limit the spread of sound waves: some of them are absorbed, some reflected and some deflected. As a result, the amount of sound waves reaching the receiver is greatly reduced and noise can be dampened by several decibels.

The advantages of a reinforced earth sound-deadening barriera

Creating reinforced earth structures brings considerable advantages:

- it costs less because you can often use earth available on-site

- no special maintenance is required other than regular trimming.

- it helps the environment and integrates with it: the use of vegetation also reduces vehicle emissions by absorbing CO 2 and purifying the air.

We will be at the EuroGeo7 Conference in Warsaw

After being postponed for so many months due to the health emergency, EUROGEO7, the 7th European Geosynthetics Conference will take place at last in Warsaw from 4 to 7 September 2022. We will be participating with our thirty years of experience and our innovative flow of products and functions.

We will be attending with ourTeMa Geo Solutions division, specialized in developing innovative technologies and products for protection, maintenance, retention, reinforcement and drainage in environmental works.

We have achieved these goals because since 1993, when TeMa was established, geosynthetic products have been our targeted approach to geotechnical and environmental applications. At a time when there was little talk of ecosystems, we developed considerable experience in this field, deploying new technologies and finding crucial improvements in terms of durability and less invasive intervention works using geosynthetic products.

The many fields of application range from the most important functions to be addressed in the fields of geotechnical engineering, reinforced earth structures and reinforced soil, to name but a few. They are highly impressive in the fields of hillside agriculture and the urban regeneration of small villages: drainage and filtration for landfills and contaminated sites; roads, railways and other transport applications; rainwater management.

What will TeMa Geo Solutions explore?

The focus is on geosynthetic products and the aspects that make them versatile, high-performance and innovative in geotechnical engineering applications. In particular, we will be focusing on TeMa Geo Solutions technologies for:

- removing seepage water using drainage geocomposites bonded with a nonwoven geotextile;

- reinforcement and stabilization with geogrids;

- the drainage capacity for the cap, bottom and sides of landfills with geonets;

- erosion control and drainage with geomats.

Our technicians will be available to provide catalogues and data sheets with performance details.

To learn more: https://www.temacorporation.com/geo-applications/

- Published in CORPORATION, Exhibitions and events, news, TeMa Technologies and Materials

New solutions in road construction and/or repairs

The safety of road infrastructures is the main goal, and maintenance work – whether preventive or supplementary – is systematic.

Road surfaces withstand heavy traffic loads and atmospheric changes with significant variations in temperature. Constant maintenance is therefore required in order to ensure even surfaces and the stability of structural elements.

Let’s look at the main factors involved in building new roads or maintaining roads.

Controlling surface erosion

Erosion is largely due to freeze/thaw cycles, which make asphalt less elastic and therefore more prone to internal voids. Such voids allow water to penetrate into underlying layers, gradually eroding the structure.

In addition, heavy traffic loads, especially heavy vehicles, cause deformation of the surface layers: this results in water penetration, which “softens” the structure and makes it less resistant.

Anti-capillary drainage

The water capillarity, i.e. the ability of liquids to move in micro-spaces even against the force of gravity, is a rather complex concept closely monitored in the construction industry. With the help of pressures exerted on lower layers, water rises upwards, dragging the finer components of materials with it and causing deformation.

It is therefore necessary to provide a drainage geocomposite, a three-dimensional membrane obtained by bonding two or more synthetic components in order to convey fluids to the exterior and prevent them from rising.

You can discover all our solutions here.

Reinforcement

It may sometimes be necessary to install reinforcement grids, especially if there is a more or less pronounced slope that would cause a road shoulder to slide downwards.

The choice of the most suitable type of reinforcement, and therefore also of the position of the geogrid in the layering, clearly depends on the problems to be faced i.e. reinforcing the surface area to limit the spread of cracks to underlying layers, improving the load-bearing capacity and reducing the stresses transmitted to lower layers, or providing a separation (and anti-contamination) function.

Discover all our solutions here.

Stabilisation

During intervention works, softer soils may be encountered, which may be subject to instability or even collapse in the early stages of intervention works. Even if this should not jeopardise the feasibility of the works, there is still the risk that the minimum legal safety requirements will be compromised.

Also in this case, geosynthetic products are the solution to the problem, as they absorb tensions at least until the intervention work achieves structural stability.

Discover the solutions in the X-Grid line here.

- Published in Drainage geocomposites and membranes, Erosion mats, GEO, Geogrids, Roads

Internationalisation is synonymous with research and flexibility

Being an international company does not mean selling abroad. It means creating or adapting products to the needs of other countries worldwide. Products that are naturally different to ours because the morphology of the land, the climate, the critical issues at stake and therefore people’s needs, are different.

In this sense, internationalisation is the result of a corporate approach to research and the technological development of products, materials and processes. Each division of the TeMa Group, namely Interior Solutions, Building Solutions and Geo Solutions, requires technical performance, a skilled workforce and know-how that is always at the cutting edge.

TeMa Group’s labs

New products, superior performance and innovative materials are the result of close interaction between our technical/design departments and our testing and quality control labs. Not only dimensional analysis and structural checks but also durability, compression and waterproofing tests are carried out in order to test the products against set quality standards. Here are some examples. For TeMa Interior Solutions, ANSI A118.10 (American National Standard Specifications) are the standard requirements for load-bearing, bonded, waterproof membranes for laying ceramic and natural stone tiles. For TeMa Building Solutions, in addition to the CE mark, membranes bear a Declaration of Performance (DOP) that certifies how they respond to the applications for which they are intended. For TeMa Geo Solutions, the UNI EN ISO 90001:2000 certified quality system ensures that the entire production is at peak performance levels.

TeMa Group partnerships

To be forward-looking and offer innovative products, materials and processes, it is essential for us to establish collaborations and partnerships with research institutes and organisations, also on a global basis. Since 2006, TeMa Technologies and Materials has been a member of IGS, the International Geosynthetics Society, an association committed to developing geosynthetic products from a scientific and engineering perspective. Its main goal is to promote the appropriate use of these materials and their related technology worldwide.

Continuous updating therefore allows us to offer innovative solutions in line with the ever-changing needs of the market. Below you will find some interesting events planned for the year 2021-2022.

EUROGEO7, in Warsaw (Poland), from 19-22 September 2021. With the spotlight on geosynthetic products, many sessions will be offered, from using these materials in new sectors to the role they will play in the circular economy.

12 ICG 2023, in Rome, from 17-21 September 2023. The 12th International Conference on Geosynthetics. The event will focus on interaction between the academic and professional worlds and on the latest technological developments in various sectors for a more resilient planet (Geosynthetics, Leading the Way to a Resilient Planet).

- Published in CORPORATION, Exhibitions and events, news, TeMa Technologies and Materials

Geosynthetics: Advantages and Applications

Our passion for work does not stop, it simply continues at our company, in a little more limited way. You certainly cannot see us running up and down building sites or going in and out of our research labs, but we can assure you that we are still working on our production of geosynthetic products with the same commitment and perseverance in order to formulate new projects and develop ideas that we will see materialised soon, once everything has ended.

TeMa and Geosynthetic Products

TeMa Geo is the TeMa division created almost thirty years ago with the aim of exploring and expanding the world of geosynthetics, which it still does today. By “geosynthetic products” we generally mean all categories of synthetic coverings that are not only used in contact with earth or other building materials but are also appreciated for their use in various building fields. In the building industry, their main advantage is that they are user-friendly in technical terms, which is why engineers and planners prefer them to other technical solutions.

The Advantages of Geosynthetics

The advantages of geosynthetic options not only lies in the fact that they are easy to use but also in their cost-effectiveness: certainly less expensive, they provide excellent performance that remains unchanged over time. Furthermore, their versatile use makes them the ideal solution to various on-site problems.

Geosynthetic Products “In the Field”: the Serravalle Project

In more practical terms, today we want to tell you about the intervention works we carried out in the Piedmont region in 2016. It involved extension works for Serravalle Retail Park. In preparation for the works, we had to make the slope in front of the new complex safe. In order to proceed, we had to prepare several reinforced soil structures, separating them into banks, and solve the problems of surface drainage for the management of water, whose catchment area was located above the area.

For works of such magnitude, we used geogrids from the XGrid PET-PVC range as a structural element. In addition, to avoid any seepage in the future, drainage elements were installed close to the reinforced structures of the horizontal sections of each berm. This is just one of our products and one of the many fields of application explored by TeMa.

To discover all our membranes, visit our section dedicated to products.

- Published in GEO, Geogrids, Reinforced earth structures, Reinforced earth structures - Drainage

Successful collaboration

In all three of its divisions, TeMa has an in-company technical department that supports and assists its customers in the various phases of implementing a project. We take care of all the details, from choosing the solution to using the method of installation.

At TeMa, our technicians use in-depth analysis and cutting-edge software to propose effective, complete and reliable solutions for any type of intervention in the field of geosynthetic products. The dimensional evaluation, structural checks and specifications of the products to be used are of considerable support for the planner or the contractor. But that’s not all. The same is also true for the most experienced operators in the sector who feel the need to expand their knowledge, gaining experience in a constantly developing field. And the outcome? Being able to propose versatile solutions in step with technologies.

The companies in the IWIS Group, including TeMa, have implemented their production plants using innovative technologies, investing in a system that ensures that soil, air and water are protected. We have three photovoltaic plants, 200 kWp, 150 kWp and 100 kWp, which allow us to use energy obtained from renewable sources. The holding company also uses recycled materials for some of its production processes, relying on 4 specific plants for recycling plastics.

TeMa Geo has the support of a research laboratory, among other things, since the company firmly believes that only constant commitment to researching and developing new solutions is the key to success and constant improvement. Collaboration between the technical office and the testing and quality laboratory, especially in the geosynthetics sector, is fundamental: it gives the company’s customers state-of-the-art solutions with researched and tested products while supporting planners and contractors with the correct installation of the proposed solutions. Tests of durability, compressive strength and drainage capacity in the most critical situations are just some of the tests that TeMa laboratories carry out daily to ensure that its products meet the strict pre-established quality standards. The fact that these products are natural and/or recycled guarantees that they are not harmful to the environment, confirming TeMa’s commitment to environmental protection.

It is precisely this continuous pursuit of excellence that has allowed TeMa to obtain UNI EN ISO 9001:2000 certification, which acknowledges a quality system with the highest levels of performance. Moreover, in compliance with the CPD (Construction Product Directive) 89/106/EEC, the product ranges proposed by TeMa have followed the procedure to obtain the CE mark.

Find out more about TeMa Geo Solutions products.

- Published in CORPORATION, GEO, Research and development