Ground reinforcement and stabilization with TeMa geogrids as part of foundation groundworks

Foundation base reinforcement for the construction of rigid reinforced concrete structures on unstable areas: a challenge for engineers across the globe. Sure enough, designers find themselves having to contend with the risk of differential foundation settlement, which can result in cracks in the structure. This means any unsound material in the area often has to be dug out and carted off site, while the layers have to be built up again using materials brought in specially, which can sometimes be expensive. The foundation bed must provide the required bearing capacity and, above all, must eliminate the risk of differential settlement.

The Katlehong job, in South Africa, was a major project for TeMa in a highly critical construction context, given that it involved building a municipal water reservoir in the shape of a 200 thousand hectolitre tank.

With the introduction of a number of geosynthetic products in place of conventional building materials, the costs came in significantly lower than initially projected and structural efficiency was improved considerably across such a large project, promising to deliver a long service life.

The TeMa solution in cases like these: laying X-Grid PET-C-0 100/100 Biax — a biaxial stabilization geogrid woven from high-strength polyester, with a protective polymer coating — over the whole bed in alternating layers with fill material between. With each new layer, the geogrid has to be placed with the appropriate orientation to ensure the structure’s foundation will provide the required overall stability and bearing capacity, thus allowing for and negating the negative effects of any differential settlement.

The use of TeMa Geo geogrids allows for space to be incorporated into the design to accommodate the underground services associated with the structure being built, while providing the designer with significant advantages, compared to the use of conventional natural materials, including ease of installation and shorter construction timeframes.

System for reinforced soil retaining structures

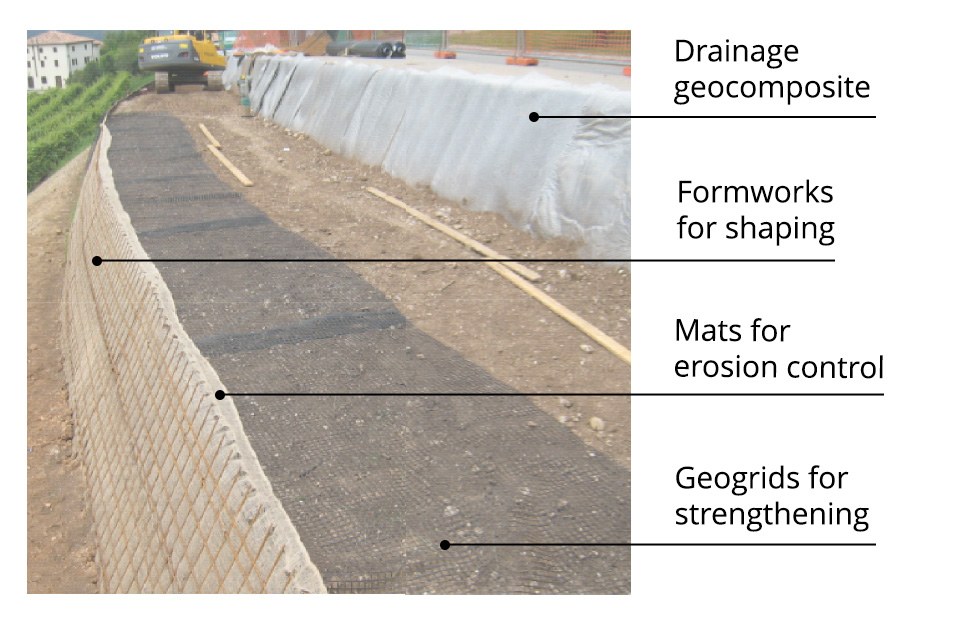

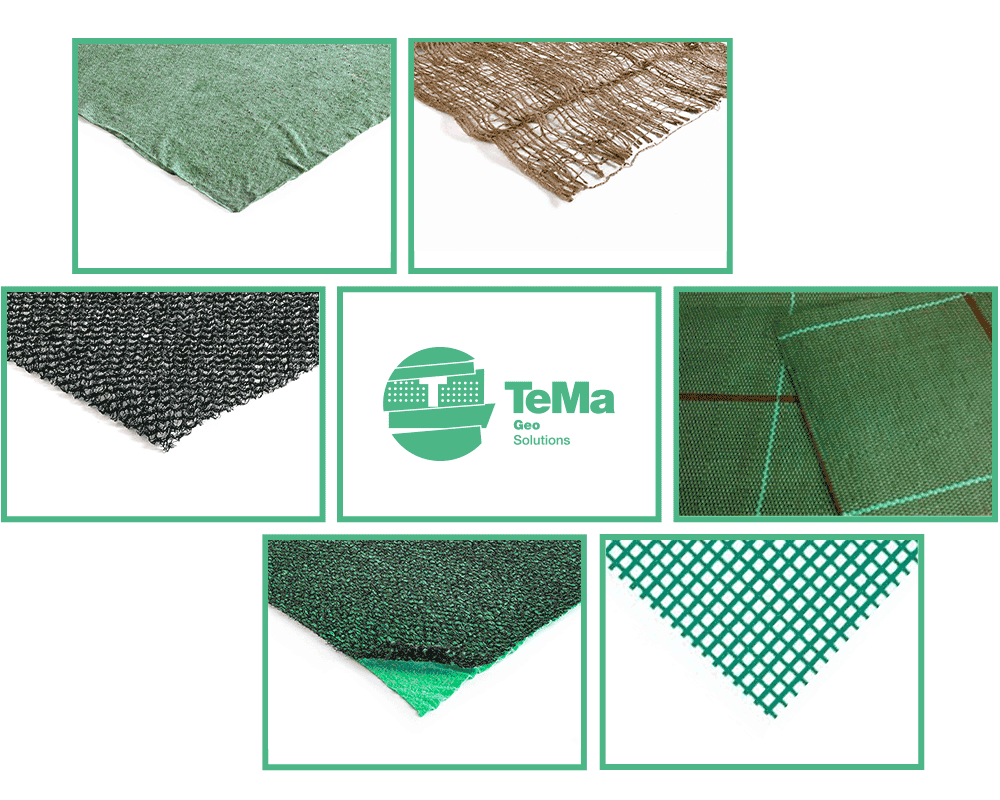

T-System is the system from TeMa Geo Solutions that includes various components for strengthening, surface erosion control, drainage and retaining used in the construction of reinforced soil retaining structures: innovation that we’ve been exploring here at TeMa since our inception 30 years ago, and that is now one of our hallmarks. Let’s take a more detailed look below.

Components for strengthening

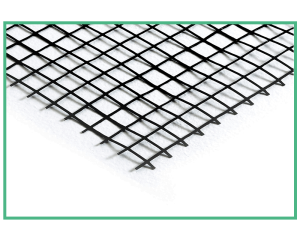

Designed for strengthening, the knitted X-Grid PET C geogrids are made from high-strength polyester yarn, with a protective polymer coating. They deliver tensile strength in the 20 kN/m to 800 kN/m range.

Components for erosion control

They protect the face of the structure from erosive agents, like wind and driving rain, until the vegetation has had time to establish. TeMa Geo Solutions offers natural solutions made from cellulose fibres, like Ecovermat, or jute fibres, like Ecovernet, as well as synthetic solutions made from monofilaments (K-Mat F), polypropylene (K-Mat FA) or fibreglass (K-Mat FG Green).

Components for drainage

Drainage geocomposites like Q-Drain are used to address the problem of water seeping into the backfill.

Components for retaining

We have a line of facings made from electrically welded wire mesh — with inclinations ranging from 65° to 80° — to ensure the exposed face is straight.

Practical tips

On site

System components must be stored well away from machinery, and suitably protected from dust or residues from work on site.

To avoid excessive overlaps and waste, the X-Grid geogrids must be cut to size using a suitable metal stand with metal trestles supporting a circular rod to be inserted inside the roll.

Erosion control components — whether biodegradable or synthetic — must be stored in a dry place and not in direct contact with the natural ground, so as to avoid laying problems later on.

Metal formwork must be stored well away from areas where machinery is operating, and carried in only when it is time to install.

During assembly, it is best to apply U-shaped strips of rubber or metal so that the geogrids can be wrapped correctly over the formwork without getting caught on the top of the bars. (see photo)

Special instructions

We advise against backfilling with silty and clayey material; at the very least, only use this kind of material after mixing it with aggregate.

The full range of system components comes with instructions on the relevant procedures to be followed. Contact us, we’ll be happy to provide case studies and full information.

TeMa at the 12th International Conference on Geosynthetics.

We too will be at the 12th edition of the International Conference on Geosynthetics that will take place in Rome, at the Parco della Musica auditorium from 17 to 21 September 2023, and which will involve a full programme of meetings between professionals (further information about the events here).

Four days of training and information meetings on geosynthetics, exploring all sub-types: woven and non-woven geotextiles, geogrids, geonets, geomats, drainage and reinforcement geocomposites, and geomembranes.

Geosynthetics are becoming increasingly popular in applications and fulfil various functions (often combined). For example:

- Drainage – drainage geocomposites and geonets.

- Filtration and Separation – woven geotextiles and non-woven geotextiles.

- Reinforcement – woven geotextiles and geogrids.

- Protection of waterproofing – studded membranes with truncated conical or star-shaped studs.

- Erosion control – geonets, geomats, biotextiles.

- Mechanical protection – non-woven geotextiles, composite geotextiles.

- Special applications – various geosynthetics made to specific requirements.

The main topics discussed will cover various fields of application, including anti-seismic design to road and railway embankments, erosion control, filtration and drainage functions, as well as an analysis of case studies.

The world of research is continuously evolving and the scheduled meetings will provide an excellent opportunity for sharing experiences and recent technical developments with engineers, geologists, consultants, contractors and whoever is involved in research and using geosynthetics.

During the exhibition event visitors will be able to take part in technical conferences, the Giroud lecture, special lectures and short courses , as well as visit the exhibition hall to meet manufacturers.

TeMa has thirty years of experience in using geosynthetics

The international event, entitled ‘Leading the way to a resilient planet’, fully represents the reason why TeMa began to manufacture and experiment with geosynthetics from the mid-1990s onwards: to research the most suitable technologies and materials for use in the construction of buildings and geotechnical works.

We have been involved in continuous interaction, also due to an increased awareness of major environmental issues. This has enabled us to broaden our range of products and expand in 80 countries worldwide.

Today, our catalogue includes many products that meet specific requirements for landfills, tunnels, road embankments, river banks and reinforced earth structures, gradually increasing performance for surface erosion control, rainwater drainage, and the reinforcement of grassy slopes.

The geosynthetics sector is rapidly developing and we are making huge investments, especially in research, so as to supply our customers with the best solutions, also tailor-made, for their projects. We share the same ‘urgency’ as our partners to pursue our unwavering ideal of respecting the environment and the hydrogeological protection of the land.

We look forward to seeing you in Rome from 17 to 21 September 2023, at Stand 22.

Meanwhile, you can discover all the details about the event here.

Reinforcement of slopes and embankments

Slopes and embankments can be used as road or railway embankments, raised flood banks and floodplains, and even vineyards, especially in a territory such as Italy, one of the countries with the largest number of UNESCO World Heritage landscapes in the world.Many of those greened terraces are true reinforced earth structures, with their stability guaranteed by a well-tested construction technique.

Stability for slopes and embankments

Reinforced earth structures are retaining works that allow slopes and embankments to be supported, including steep slopes. They do not involve the use of concrete constructions, which would be more detrimental to the landscape.

The soil has a natural capacity for compressive strength. When combined with geosynthetic grids (which have excellent tensile strength), they create a stable system, as the features of the two components provide a high-performance composite.

The open mesh structure allows reinforcement geogrids to develop passive resistance along the transverse ribs, as well as creep resistance of the geosynthetic grid in relation to the soil. The TeMa Geo Solutions range includes X-Grid geogrids, available in a variety of models depending on the type of project.

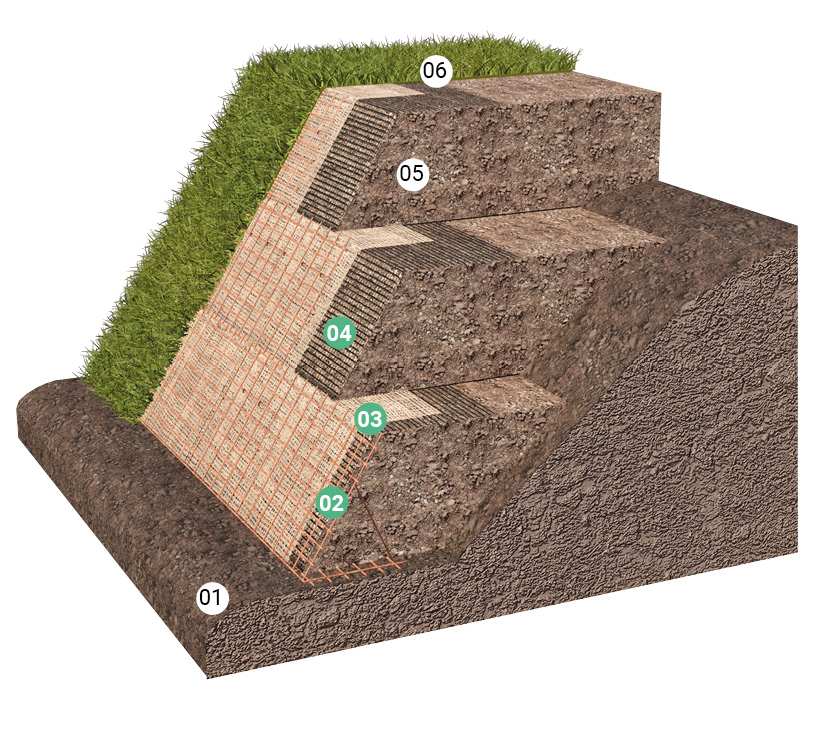

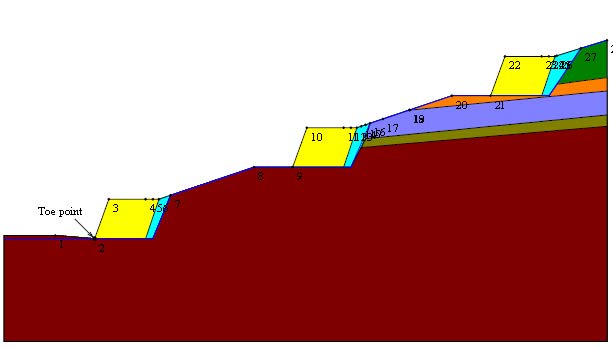

How to position the geogrid in the layering of a terrain?

Each slope needs to be carefully and expertly engineered. However, in addition to the need to reinforce the raised earth structure with geogrids, it is essential to ensure surface erosion control using synthetic or natural erosion control mats and shaping with electro-welded wire mesh formwork.

The X-Grid geogrid must be applied to each ‘block’ of soil supported by the formwork, positioned between the backfill soil and the erosion control mat. An external wrap-around part, measuring no more than 150 cm, must be provided for the formwork system by installing formwork stiffening ribs approximately 30 cm apart.

- Foundation soil

- Metal formwork

- Erosion control mat

- Geogrid

- Backfill soil

- Grassed surface

- Published in environmental, GEO, Geogrids, Reinforced earth structures

Cycle and pedestrian paths: solutions to make them safer and more attractive.

Longer days, milder afternoons, a great desire to spend time outdoors and perhaps get some physical exercise, but also go to work and school or visit a friend… These are all good reasons for using, when available, cycle and pedestrian paths, possibly far from urban traffic.

The advantages of sustainable mobility

We are increasingly talking about environmental sustainability and the physical and psychological benefits of physical exercise:

- Less air and noise pollution caused by traffic.

- Reduced transport costs.

- Greater freedom of movement.

- Enhanced green areas in cities.

- Better quality of life by doing a bit of sport on a daily basis.

TeMa Geo Solutions for safety and urban benefits

‘Unequipped’ roads can be hazardous for those who choose to get around by bicycle: for this and environmental reasons, cycle and pedestrian paths are the ideal solution, as they are increasingly becoming part of local government mobility plans.

TeMa Geo Solutions offers all its experience by combining reinforced earth structures and their feature of being green, with cycle and pedestrian paths.

An embankment can be made or a road widened with its sides sloping at 65°/70° using the T-System (consisting of formworks, X-Grid PET geogrids and K-Mat FG Green erosion control mats as facing), thereby making the path safe and allowing a slope to turn green again. Making a slope green again provides a natural erosion control function: to encourage it, TeMa Geo Solutions recommends installing natural or synthetic mats. To make the structure stable, the T-System for reinforced soils adopted by TeMa involves using X-Grid PET geogrids.

Reinforced earth structures and drainage

For the extension works at the Serravalle Retail Park shopping centre in the Piedmont region, we helped the company choose the solutions to implement and assisted with verifications.

The area covering about 2,000 sqm required some intervention work regarding reinforced earth structures and drainage. In particular, we undertook the preliminary work for extension works dating back to 2016.

To the south-west of the building, the soil was secured and then surfaces were replanted with greenery.

Let’s see how this was done in more detail.

Type of intervention

In order to make the slope in front of the complex secure, the intervention work involved constructing reinforced earth structures in several banks, more specifically 3 modules of 6 m in height each.

In addition, to manage the water coming from the hydro-geographic basin situated upstream of the area, specific surface drainage works were carried out.

The solution from TeMa Geo Solutions

For the reinforced earth structure, 3 modules were constructed with anchorage lengths of 7 m and a strength of 110 kN/m provided by X-Grid PET PC 110 geogrids.

As for drainage, instead, a Membrana Nera Geo was used, the 8 mm HDPE studded membrane bonded to a filter nonwoven geotextile with a PE slotted tube at the base.

The drainage system was also installed at the horizontal contact points of each berm to prevent future water seepage into the reinforced earth structure.

Reinforced earth structures as noise barriers

Hearing the noise of traffic outside your window all day long is irritating and distracting and, in the long term, also harmful to your health.

This is why the WHO and a number of laws govern the use of noise remediation systems in cities: the Framework Law no. 447 of 1995 for Italy and the European Directive on Environmental Noise no. 49/2022. If the cause of the noise cannot be addressed, the solution is to install protective barriers. Various kinds can be used, but in this case we focus on reinforced earth structures that require specific measures, which we discuss here.

For example, the Pedemontana Veneta is a new toll motorway in Italy: nearly 100 km long. Almost entirely in operation in the north-east of the Veneto region, the main route of this motorway runs through a deep trench in order to minimise the ‘territorial’ and environmental impact on the surrounding area. This means that long sloping areas of reinforced earth can be found along the sides of the motorway, with rows of trees and hedges for 58.61 km and green areas covering 1,333,410 square metres of hedgerows, groves, grassy slopes and tree-lined meadows.

A focus on noise with much regard for the landscape.

What do reinforced earth noise barriers consist of?

For this type of embankment with its typical trapezoidal shape, earth is used that will be covered by vegetation over time. Geosynthetic reinforcements and geogrids are added to support the earth, which already has good compressive strength. These are inserted horizontally into the ground and develop friction and tension that stabilise the structure, increasing its resistance to stress.

The TeMa Geo Solutions offer includes the X-Grid Pet PVC range of geogrids, with different resistance values, which are ideal for all kinds of contexts.

Another aspect to bear in mind is surface erosion of the soil: to counteract this, synthetic geomats are applied, also with a mulching function to encourage the growth of grass cover, or natural fibre bionets.

Also in this case, TeMa Geo Solutions offers a wide choice ranging from Ecovermat F Grass and Ecovernet FJ to the K-Mat range.

Why use a vegetation barrier as a protective noise barrier?

A vegetation barrier has an unquestionable ability to limit the spread of sound waves: some of them are absorbed, some reflected and some deflected. As a result, the amount of sound waves reaching the receiver is greatly reduced and noise can be dampened by several decibels.

The advantages of a reinforced earth sound-deadening barriera

Creating reinforced earth structures brings considerable advantages:

- it costs less because you can often use earth available on-site

- no special maintenance is required other than regular trimming.

- it helps the environment and integrates with it: the use of vegetation also reduces vehicle emissions by absorbing CO 2 and purifying the air.

New solutions in road construction and/or repairs

The safety of road infrastructures is the main goal, and maintenance work – whether preventive or supplementary – is systematic.

Road surfaces withstand heavy traffic loads and atmospheric changes with significant variations in temperature. Constant maintenance is therefore required in order to ensure even surfaces and the stability of structural elements.

Let’s look at the main factors involved in building new roads or maintaining roads.

Controlling surface erosion

Erosion is largely due to freeze/thaw cycles, which make asphalt less elastic and therefore more prone to internal voids. Such voids allow water to penetrate into underlying layers, gradually eroding the structure.

In addition, heavy traffic loads, especially heavy vehicles, cause deformation of the surface layers: this results in water penetration, which “softens” the structure and makes it less resistant.

Anti-capillary drainage

The water capillarity, i.e. the ability of liquids to move in micro-spaces even against the force of gravity, is a rather complex concept closely monitored in the construction industry. With the help of pressures exerted on lower layers, water rises upwards, dragging the finer components of materials with it and causing deformation.

It is therefore necessary to provide a drainage geocomposite, a three-dimensional membrane obtained by bonding two or more synthetic components in order to convey fluids to the exterior and prevent them from rising.

You can discover all our solutions here.

Reinforcement

It may sometimes be necessary to install reinforcement grids, especially if there is a more or less pronounced slope that would cause a road shoulder to slide downwards.

The choice of the most suitable type of reinforcement, and therefore also of the position of the geogrid in the layering, clearly depends on the problems to be faced i.e. reinforcing the surface area to limit the spread of cracks to underlying layers, improving the load-bearing capacity and reducing the stresses transmitted to lower layers, or providing a separation (and anti-contamination) function.

Discover all our solutions here.

Stabilisation

During intervention works, softer soils may be encountered, which may be subject to instability or even collapse in the early stages of intervention works. Even if this should not jeopardise the feasibility of the works, there is still the risk that the minimum legal safety requirements will be compromised.

Also in this case, geosynthetic products are the solution to the problem, as they absorb tensions at least until the intervention work achieves structural stability.

Discover the solutions in the X-Grid line here.

- Published in Drainage geocomposites and membranes, Erosion mats, GEO, Geogrids, Roads

The importance of geogrids in reinforced earth structures

In recent years, reinforced earth structures have been particularly popular in projects due to their excellent functional and aesthetic importance in the residential building and public building industries.

Such intervention works achieve the best results by allowing the soil and geosynthetics to “work in synergy”, each one with its own features of ensuring the stability of the work as a whole.

It’s easy to see the high environmental value of such solutions, but let’s take a closer look at the two major factors in reinforced soil works. In this way, we can understand how and why, working together, they lead to amazing results, also in aesthetic terms.

What are reinforced earth structures?

They are structural intervention works in various gradients and dimensions aimed at retention and/or stabilisation. We can identify a few main areas of application:

- Road and railway embankments.

- Restoration and consolidation of collapsed soil on a road.

- Construction of ramps for ascending and descending flyovers.

- Canal or river bank elevations.

- Rockfall barriers.

- Noise barriers along roads or railways.

- Widening of elevated car parks.

- Construction of terracing systems in vineyards.

- Soil consolidation at tunnel entrances.

What are geogrids and why are they often the best solution?

Soil has the intrinsic features of friction and compressive strength, but practically no tensile strength. This is not enough to ensure the stability of a structure.

Major slopes, weather conditions, proximity to embankments, etc. can erode soil, causing landslides and subsidence. For reinforced earth structures, it’s therefore necessary to use geogrids, two-dimensional structures horizontally inserted into soil, which integrate with it without deforming. Their open-mesh structure develops “passive” resistance, thereby increasing the stabilising effect.

This bonding exploits the abilities of the two construction elements, making the entire structure more efficient.

Naturally, the feasibility of retaining works needs to consider:

- the intrinsic characteristics of the soil, such as grain size, the degree of thickening and shear strength, as well as the dilatancy phenomenon;

- the characteristics of the geogrids, such as tensile strength and stiffness, the use of raw materials (polymers) that can also withstand harsh chemical and physical conditions (attacks by chemical agents, soil pH, etc.), and the appropriate geometric structure.

Greening

Eventually, grass will grow and none of the intervention work will be visible: a really attractive and natural reinforced structure. In addition to its aesthetic function, greening also plays an important role in helping the natural friction of soil.

Find out more about our products here.

Geosynthetics: Advantages and Applications

Our passion for work does not stop, it simply continues at our company, in a little more limited way. You certainly cannot see us running up and down building sites or going in and out of our research labs, but we can assure you that we are still working on our production of geosynthetic products with the same commitment and perseverance in order to formulate new projects and develop ideas that we will see materialised soon, once everything has ended.

TeMa and Geosynthetic Products

TeMa Geo is the TeMa division created almost thirty years ago with the aim of exploring and expanding the world of geosynthetics, which it still does today. By “geosynthetic products” we generally mean all categories of synthetic coverings that are not only used in contact with earth or other building materials but are also appreciated for their use in various building fields. In the building industry, their main advantage is that they are user-friendly in technical terms, which is why engineers and planners prefer them to other technical solutions.

The Advantages of Geosynthetics

The advantages of geosynthetic options not only lies in the fact that they are easy to use but also in their cost-effectiveness: certainly less expensive, they provide excellent performance that remains unchanged over time. Furthermore, their versatile use makes them the ideal solution to various on-site problems.

Geosynthetic Products “In the Field”: the Serravalle Project

In more practical terms, today we want to tell you about the intervention works we carried out in the Piedmont region in 2016. It involved extension works for Serravalle Retail Park. In preparation for the works, we had to make the slope in front of the new complex safe. In order to proceed, we had to prepare several reinforced soil structures, separating them into banks, and solve the problems of surface drainage for the management of water, whose catchment area was located above the area.

For works of such magnitude, we used geogrids from the XGrid PET-PVC range as a structural element. In addition, to avoid any seepage in the future, drainage elements were installed close to the reinforced structures of the horizontal sections of each berm. This is just one of our products and one of the many fields of application explored by TeMa.

To discover all our membranes, visit our section dedicated to products.

- Published in GEO, Geogrids, Reinforced earth structures, Reinforced earth structures - Drainage

- 1

- 2