TeMa at the 12th International Conference on Geosynthetics.

We too will be at the 12th edition of the International Conference on Geosynthetics that will take place in Rome, at the Parco della Musica auditorium from 17 to 21 September 2023, and which will involve a full programme of meetings between professionals (further information about the events here).

Four days of training and information meetings on geosynthetics, exploring all sub-types: woven and non-woven geotextiles, geogrids, geonets, geomats, drainage and reinforcement geocomposites, and geomembranes.

Geosynthetics are becoming increasingly popular in applications and fulfil various functions (often combined). For example:

- Drainage – drainage geocomposites and geonets.

- Filtration and Separation – woven geotextiles and non-woven geotextiles.

- Reinforcement – woven geotextiles and geogrids.

- Protection of waterproofing – studded membranes with truncated conical or star-shaped studs.

- Erosion control – geonets, geomats, biotextiles.

- Mechanical protection – non-woven geotextiles, composite geotextiles.

- Special applications – various geosynthetics made to specific requirements.

The main topics discussed will cover various fields of application, including anti-seismic design to road and railway embankments, erosion control, filtration and drainage functions, as well as an analysis of case studies.

The world of research is continuously evolving and the scheduled meetings will provide an excellent opportunity for sharing experiences and recent technical developments with engineers, geologists, consultants, contractors and whoever is involved in research and using geosynthetics.

During the exhibition event visitors will be able to take part in technical conferences, the Giroud lecture, special lectures and short courses , as well as visit the exhibition hall to meet manufacturers.

TeMa has thirty years of experience in using geosynthetics

The international event, entitled ‘Leading the way to a resilient planet’, fully represents the reason why TeMa began to manufacture and experiment with geosynthetics from the mid-1990s onwards: to research the most suitable technologies and materials for use in the construction of buildings and geotechnical works.

We have been involved in continuous interaction, also due to an increased awareness of major environmental issues. This has enabled us to broaden our range of products and expand in 80 countries worldwide.

Today, our catalogue includes many products that meet specific requirements for landfills, tunnels, road embankments, river banks and reinforced earth structures, gradually increasing performance for surface erosion control, rainwater drainage, and the reinforcement of grassy slopes.

The geosynthetics sector is rapidly developing and we are making huge investments, especially in research, so as to supply our customers with the best solutions, also tailor-made, for their projects. We share the same ‘urgency’ as our partners to pursue our unwavering ideal of respecting the environment and the hydrogeological protection of the land.

We look forward to seeing you in Rome from 17 to 21 September 2023, at Stand 22.

Meanwhile, you can discover all the details about the event here.

- Published in Drainage geocomposites and membranes, environmental, GEO, Geogrids, Reinforced earth structures - Drainage, Reinforced earth structures - Erosion control

Drainage for diaphragms and berlin walls: a practical and safe solution

Some of the most widely used works in the civil engineering field are diaphragms and berlin walls, which counteract strong thrusts of the soil and prevent landslides and structural subsidence.

Diaphragms are supporting walls consisting of pointed vertical elements (piles) or continuous elements (walls) made of steel or reinforced concrete. They are driven into the ground to a considerable depth, whereas Berlin walls are flexible retaining structures constructed with vertical micro-piles.

Both solutions are used where it’s impossible to construct excavation walls of an adequate gradient due to the presence of other nearby structures and to the morphology of the area , which imposes limited work spaces (that would make manoeuvring large machinery impossible).

Berlin walls made of micro-piles are one of the most popular applications on construction sites for implementing waterproof retaining works. The technique allows work to be carried out on almost all types of terrain, especially when it’s necessary to use on-site systems that are smaller than in the past.

Since works are in contact with the ground, the drainage aspect should not be underestimated. If rainwater and groundwater exert pressure on the vertical wall, they may damage the waterproofing. TeMa Building Solutions therefore has the right product for this application: T-Mix Drain WP, the geocomposite that not only drains but also provides the functions of filtration, separation and stay-in-place formwork.

TeMa has acquired considerable experience with geocomposites. For many years, the company has been providing this system to replace the conventional gravel drainage system. The results are long-lasting and it’s the ideal solution: compared to conventional gravel, it’s less bulky, easily transported and quick to install. This reduces the costs of transport and implementation and on-site construction time while, last but not least, resulting in considerable savings in terms of CO2.

Fields of application

As mentioned above, diaphragms and berlin walls are widely used where space is limited. More specifically, they can be used in the construction industry, for example for underground garages in homes or commercial premises, for basements. They can also be used in river works, such as quays and piers for boats, or in earth dams and wells.

Having the experience of TeMa technicians and tested effective products such as T-Mix Drain WP at your disposal is therefore a guarantee for your construction site.

TeMa even more transparent about sustainability

With the new EPD certification, TeMa Technologies and Materials provides information about the level of sustainability of its products: this includes most of the membranes and geocomposites manufactured on its production lines. For 30 years, TeMa has regarded environmental protection as a duty and obligation towards the community and future generations.

What is EPD and what is analysed to obtain it?

The Environmental Product Declaration (EPD) is a document that provides specific data on the life cycle of products or a service. It measures the impacts that the production and life phases of a product have on the environment by means of a Life Cycle Assessment to determine the consumption of resources such as water, materials and energy.

It is voluntary and verified by the independent third party SGS so that certified declarations can be given to clients.

International acknowledgement

The EPD document is internationally acknowledged, as it complies with ISO standards. This ensures use, credibility and stability over time, making the data collected available for use in any type of environmental management system and providing information for environmental certification protocols for buildings and infrastructures.

Which product lines from TeMa Building Solutions are EPD certified?

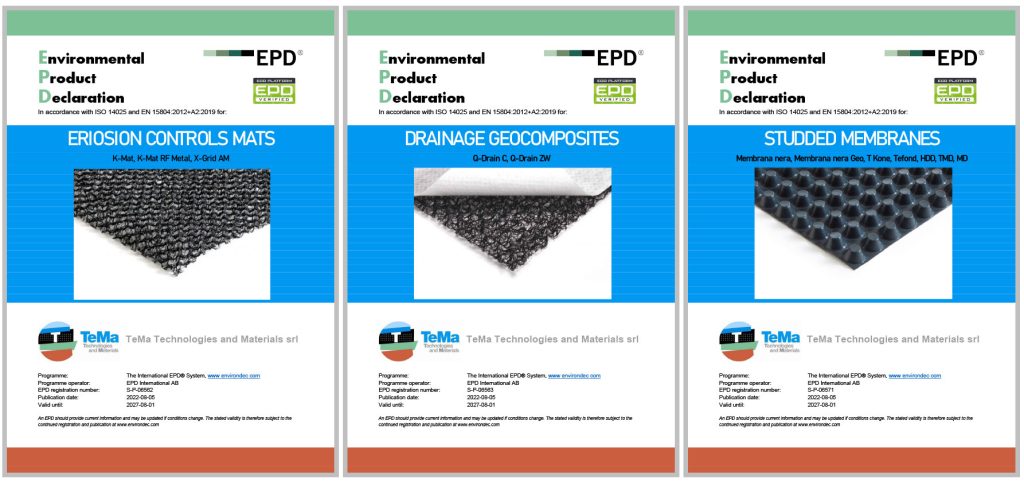

The products having obtained EPD certification are:

- the studded membrane line, which includes Membrana Nera, Membrana Nera Geo, T-Kone, Tefond, HDD, TM and MD;

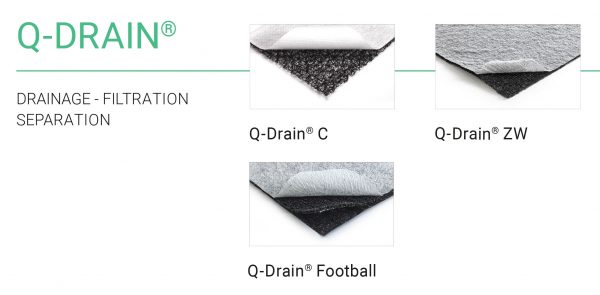

- the monofilament drainage line comprising Q-Drain C and Q-Drain ZW;

- the anti-erosion and reinforcement geomat line, which includes K-Mat and X-Grid AM.

Our certificates can always be consulted by clicking here and entering TeMa in the filters.

- Published in CORPORATION, news, TeMa Technologies and Materials

New solutions in road construction and/or repairs

The safety of road infrastructures is the main goal, and maintenance work – whether preventive or supplementary – is systematic.

Road surfaces withstand heavy traffic loads and atmospheric changes with significant variations in temperature. Constant maintenance is therefore required in order to ensure even surfaces and the stability of structural elements.

Let’s look at the main factors involved in building new roads or maintaining roads.

Controlling surface erosion

Erosion is largely due to freeze/thaw cycles, which make asphalt less elastic and therefore more prone to internal voids. Such voids allow water to penetrate into underlying layers, gradually eroding the structure.

In addition, heavy traffic loads, especially heavy vehicles, cause deformation of the surface layers: this results in water penetration, which “softens” the structure and makes it less resistant.

Anti-capillary drainage

The water capillarity, i.e. the ability of liquids to move in micro-spaces even against the force of gravity, is a rather complex concept closely monitored in the construction industry. With the help of pressures exerted on lower layers, water rises upwards, dragging the finer components of materials with it and causing deformation.

It is therefore necessary to provide a drainage geocomposite, a three-dimensional membrane obtained by bonding two or more synthetic components in order to convey fluids to the exterior and prevent them from rising.

You can discover all our solutions here.

Reinforcement

It may sometimes be necessary to install reinforcement grids, especially if there is a more or less pronounced slope that would cause a road shoulder to slide downwards.

The choice of the most suitable type of reinforcement, and therefore also of the position of the geogrid in the layering, clearly depends on the problems to be faced i.e. reinforcing the surface area to limit the spread of cracks to underlying layers, improving the load-bearing capacity and reducing the stresses transmitted to lower layers, or providing a separation (and anti-contamination) function.

Discover all our solutions here.

Stabilisation

During intervention works, softer soils may be encountered, which may be subject to instability or even collapse in the early stages of intervention works. Even if this should not jeopardise the feasibility of the works, there is still the risk that the minimum legal safety requirements will be compromised.

Also in this case, geosynthetic products are the solution to the problem, as they absorb tensions at least until the intervention work achieves structural stability.

Discover the solutions in the X-Grid line here.

- Published in Drainage geocomposites and membranes, Erosion mats, GEO, Geogrids, Roads

Why don’t puddles form on soccer fields?

Let’s take a step back: nowadays, synthetic turf fields are the most cost-effective solution for football clubs, for both the first team and the youth sector. So, the construction of a synthetic system is an opportunity not to be missed. It is therefore important to construct a synthetic field that is ideal for the type of use and level of play.

TeMa staff can assist in the construction – especially in the design phase – to define the characteristics of the synthetic turf field. We are very familiar with the different layers it is made of (sub-base, turf and sand, rubber or natural infill) and its various features recommended by experience depending on different climatic conditions. The initial step is also important for determining the procedure that any club – in almost all cases through the municipality, the owner – needs to follow in order to construct the most suitable synthetic field in terms of type and frequency of use.

The secret is…

…drainage. Having a quality sub-base is even more important than the surface turf. This is where the experience of TeMa steps in with the company’s drainage solutions, developed on 4 continents. They guarantee the timely disposal of water in the quickest possible time and the use of the field even in severe weather conditions.

Drainage of a synthetic turf field

On synthetic turf fields water drainage is horizontal: after stabilising and levelling the surface, an impermeable membrane is applied that prevents liquids from penetrating into the ground below, conveying them to the channels on the long sides of the field.

This prevents water from stagnating on the surface of the field, avoiding puddles and the removal of surface material.

Natural or synthetic turf for the field?

A natural grass surface requires more maintenance and higher costs: it needs to be cut at regular intervals, treated, fertilised and watered. Moreover, weather conditions may affect the use of the field.

By contrast, synthetic turf is more resistant to weather conditions. It can also be used intensively all the time, regardless of the season and requires much less maintenance: it only needs to be “combed” regularly to revitalise the turf.

In addition to the (much) shorter construction time, a factor that tends to make synthetic turf preferable to natural turf is its permeable capacity: the control over water filtration is clearly superior and the sub-base is designed to drain excess water during heavy rainfall and/or store it. This makes it easier to maintain favourable conditions for both the game and the durability of the field, while also protecting the health of the players.

What makes the field so even and linear?

Drainage geocomposites provide maximum performance.

Q-Drain ZW8 Football consists of a monofilament core bonded with two non-woven fabrics, to which a PE membrane can be added if required.

Q-Drain ZW8 WP Football, ideal for horizontal drainage applications, consists of a monofilament core bonded with a non-woven fabric and a waterproofing film.

To support these products, we recommend T-Kanal Football, a cement channel for perimeter drainage that contains a special drainage membrane. The system is made complete with a grid, fixings and T-Tape, for joining the rolls during installation.

- Published in GEO, Synthetic turf soccer fields - Accessories

Environmental intervention works in keeping with our philosophy

An environmental reappraisal

Over the centuries the relationship between man and the environment has undergone considerable tensions. Rural development and the impetus in building have undoubtedly disrupted certain landscapes, reducing natural spaces to accommodate new urban and agricultural areas. This type of intervention work has led to a crisis in the ecosystem, imposing re-evaluation of the fragile balance between the economy and the environment.

This is the socio-cultural background that has led to global re-assessment aimed at defining programmes and new territorial management formulas. It has been the driving force behind TeMa Geo Solutions, the TeMa business unit dedicated to environmental intervention works. These are aimed at protecting land and offering the opportunity to operate using eco-compatible solutions and products that integrate into the environment without compromising its appearance or safety.

Sustainable development according to TeMa

Nestled at the foot of the hills declared a UNESCO World Heritage Site, the TeMa headquarters could not help but consistently correspond to this desire for sustainability, widespread in this area for some years now. But how has it contributed? By using raw materials responsibly, with 100% natural solutions and intervention procedures with low environmental impact.

Natural products

As a concrete example, TeMa addresses the problem of surface erosion of the soil by meteoric rain with Ecovernet® in natural fibres such as jute or Ecovermat® in natural fibres such as straw and coconut – or in biodegradable cellulose fibre. Installing products in this range allows intervention works to be carried out immediately, even in situations with difficult access for on-site vehicles. For such types of intervention works, total integration with the soil is achieved, guaranteeing lasting results over time.

Green intervention works

An interesting new development introduced by our technicians is the use of lightweight materials that feature reduced encumbrance, which not only affects the cost of the work but also speeds up the time required on-site. When building drainage systems, for example, TeMa does not rely on that range of inert materials from quarries that need to be extracted and transported. The company uses drainage geocomposites instead, such as Q-Drain, thus avoiding any waste of energy and CO₂ emissions into the air, thus ensuring quick installation.

These are just a few examples to show the potential that the field of environmental engineering has to offer:

- Reduction in costs while maintaining the effectiveness of intervention works

- Sustainability of the actions taken

- Protection and safeguarding of the soil

- Promotion of natural raw materials

To fully understand our philosophy, browse through the new catalogue dedicated to the protection of vineyards, which are the natural and cultural heritage of our lands and an identifying feature of our history. Inside it, you will find products and solutions for responsible and eco-compatible actions.

- Published in Drainage geocomposites and membranes, Erosion mats, GEO, Research and development