For vertical applications, such as foundation walls, and for horizontal applications, such as flat roofs, mechanical protection of waterproofing is required and, often, also drainage: TMD 1011 is a studded membrane, produced by TeMa Building Solutions, that performs both functions: drainage for vertical applications and waterproofing protection for horizontal applications.

A few tips for laying TMD 1011 on horizontal surfaces

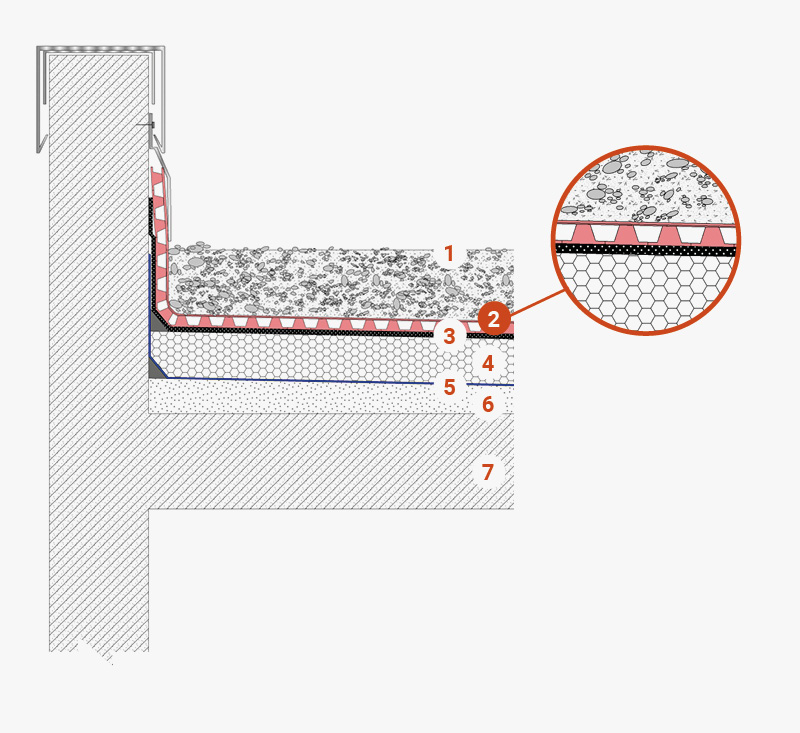

Flat roof with gravel finish (weighted)

1 Gravel finish

2 TMD 1011 membrane serving as a drainage layer and for waterproofing protection

3 Waterproofing membrane

4 Thermal and acoustic insulation

5 Vapour barrier

6 Sloping underlayment

7 Load-bearing structure

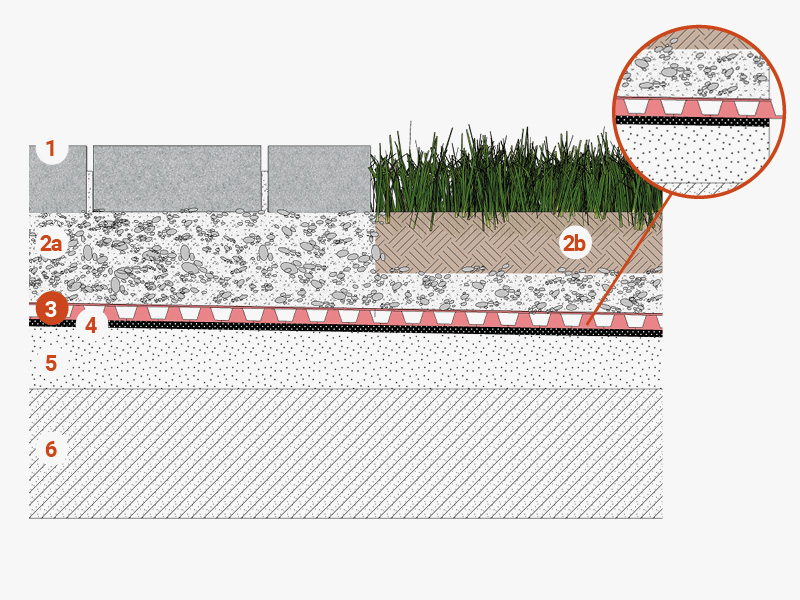

Walkways and green areas

Walkways and green areas

1 Interlocking block paving

2a Crushed stone bedding course

2b Growing medium

3 TMD 1011 membrane serving as a drainage layer and for waterproofing protection

4 Waterproofing membrane

5 Vapour barrier

6 Sloping underlayment

7 Load-bearing structure

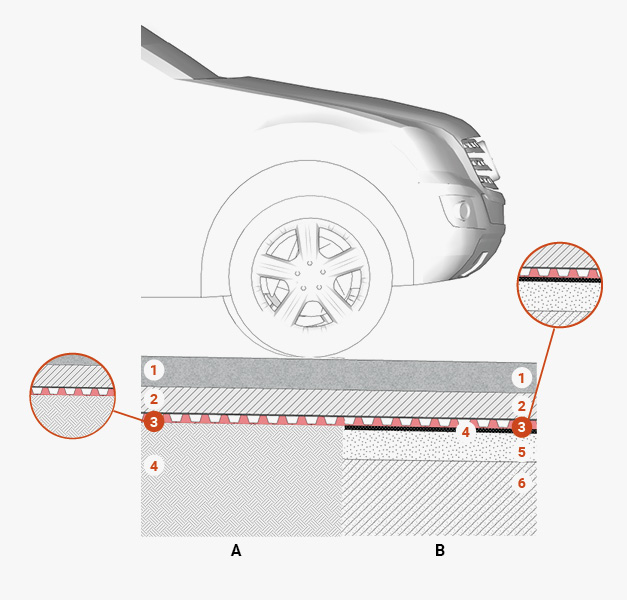

Surfaces suitable for vehicle traffic A

1 Paving designed to take vehicle loads

2 Sand bedding layer

3 TMD 1011 membrane serving as a:

– drainage layer

– substrate in place of traditional concrete levelling compounds

– separating and leachate containment layer (oils or hydrocarbons)

4 Substructure / ground

Surfaces suitable for vehicle traffic B

1 Paving designed to take vehicle loads

2 Sand bedding layer

3 TMD 1011 membrane serving as a drainage layer and for waterproofing protection

4 Waterproofing membrane

5 Sloping underlayment

6 Load-bearing structure

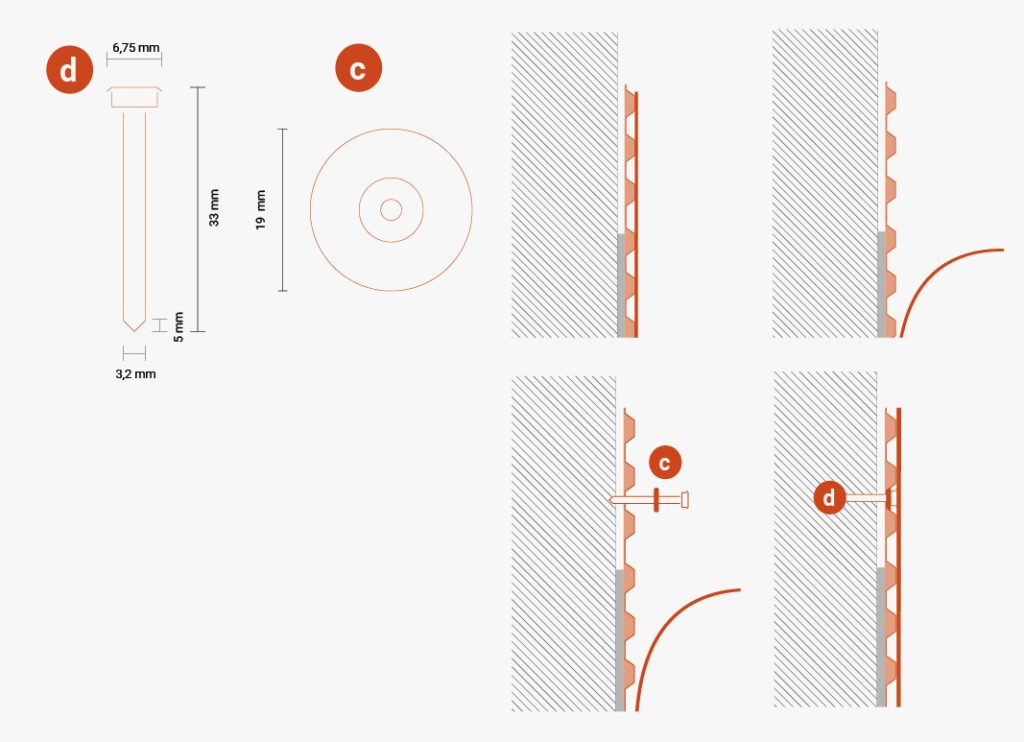

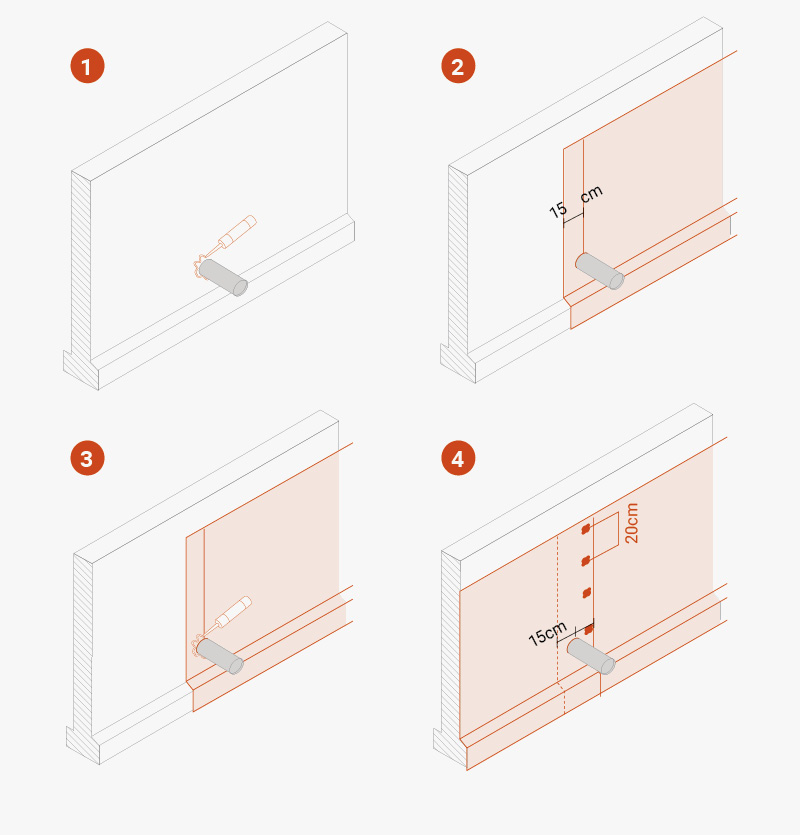

A few tips for laying TMD 1011 on vertical surfaces

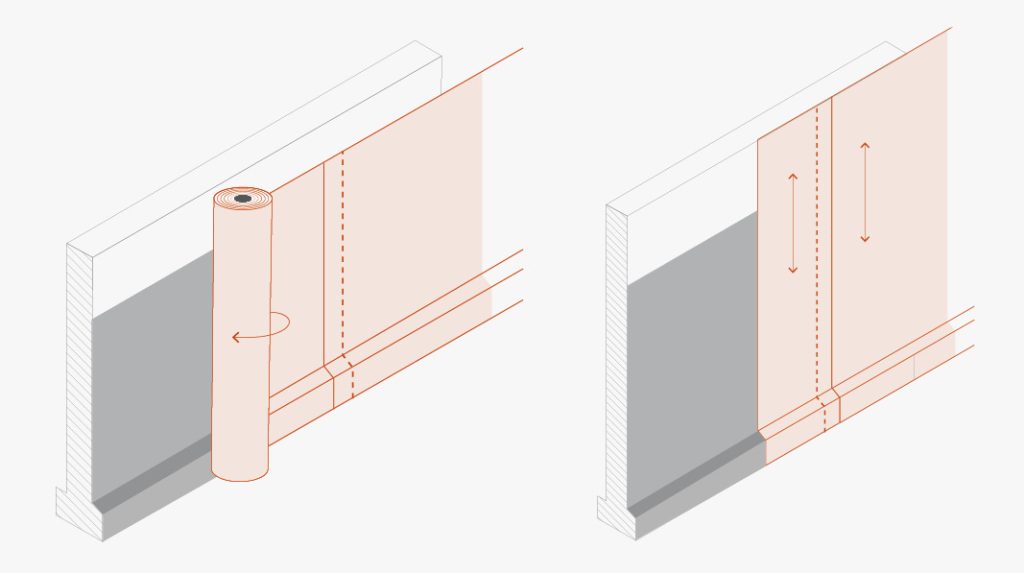

Unroll the membrane and install it vertically or horizontally: in the latter case, the width of the roll corresponds to the height of the wall to be protected. Two consecutive membranes should overlap by about 20 cm, and the studs should interlock.

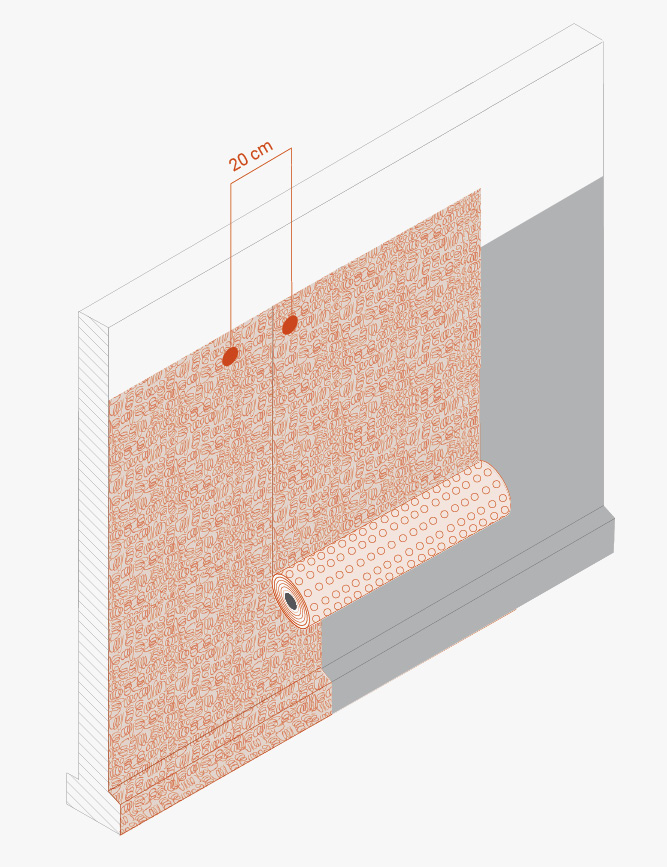

For horizontal joints, if the TMD 1011 membrane is not wide enough to completely cover the height of the installation, the first layer should be installed from the base upwards and then, keeping an overlap of at least 15 cm, the second layer should be installed by overlapping the first layer outwards (i.e. towards the side away from the wall). Install washers every 20 cm in the overlapping area.

Inlets for utility connections, such as water, gas, sewers or similar pipelines

- Place mastic sealant around the pipeline or inlet.

- Cut the TMD 1011 membrane vertically so that it extends 15 cm beyond the pipeline or inlet, trimming the membrane so that it adheres as tightly as possible.

- Put mastic sealant on the membrane so that there is a layer of mastic both above and below the membrane around the pipeline or inlet.

- Start the next installation of the membrane 15 cm before the pipeline or inlet so that the overlap around the pipeline or inlet is 30 cm. Trim again around the pipeline or inlet for watertightness.

- Install fasteners every 20 cm along the edge of the overlapping membrane.

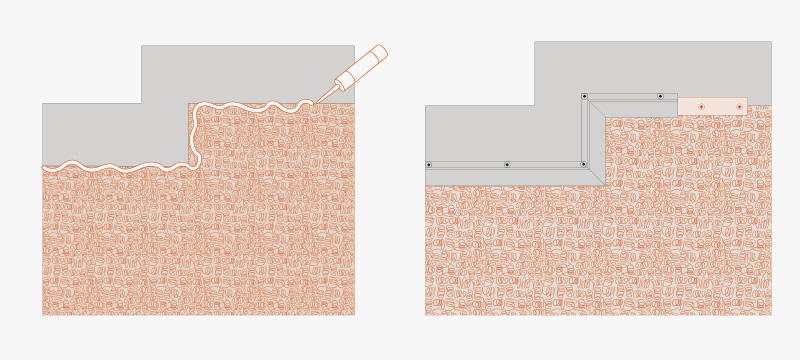

Change of level or areas where the smooth part has been trimmed

Use T-Profile + T-Nails to seal the edge, using a sealant for the area to ensure that the edge is properly sealed.

TMD 1011 should also be protected with T-Profile to prevent soil from penetrating into the gap between the wall and membrane. Then, fasten it using washers and nails with T-Nails spaced at intervals of 20-30 cm, either along the upper edge of the studded membrane or along the profile.