TeMa South Africa and Naue collaborate to serve South Africa and project-related sub-Saharan Africa

TeMa South Africa has been appointed as the official representative of Naue in South Africa and for project-related opportunities in sub-Saharan Africa.

This partnership builds on an existing relationship between TeMa and Naue in the Italian market.

The products commercialized prior to this new agreement were mainly regarding TeMa Geo and its environmental field of application, but are now expanding with a larger range of products.

For more information, please reach out to:

Darryn Meisel Managing Director TeMa SA and Nicolas Lewarne Business Development TeMa SA (see their contacts on page 3) or through our websites!

Read or download the full press release: TeMa South Africa collaborates with NAUE

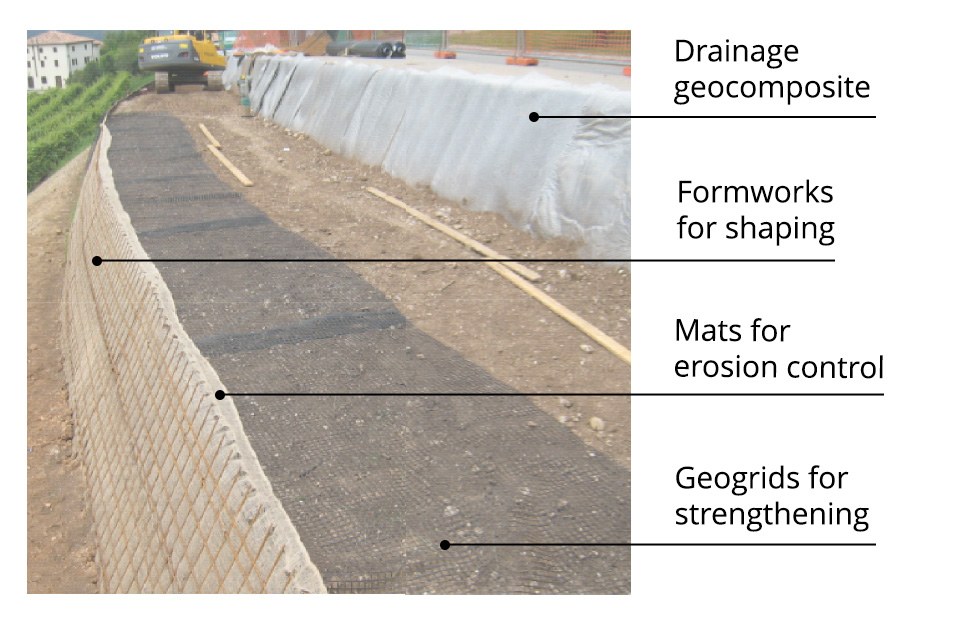

System for reinforced soil retaining structures

T-System is the system from TeMa Geo Solutions that includes various components for strengthening, surface erosion control, drainage and retaining used in the construction of reinforced soil retaining structures: innovation that we’ve been exploring here at TeMa since our inception 30 years ago, and that is now one of our hallmarks. Let’s take a more detailed look below.

Components for strengthening

Designed for strengthening, the knitted X-Grid PET C geogrids are made from high-strength polyester yarn, with a protective polymer coating. They deliver tensile strength in the 20 kN/m to 800 kN/m range.

Components for erosion control

They protect the face of the structure from erosive agents, like wind and driving rain, until the vegetation has had time to establish. TeMa Geo Solutions offers natural solutions made from cellulose fibres, like Ecovermat, or jute fibres, like Ecovernet, as well as synthetic solutions made from monofilaments (K-Mat F), polypropylene (K-Mat FA) or fibreglass (K-Mat FG Green).

Components for drainage

Drainage geocomposites like Q-Drain are used to address the problem of water seeping into the backfill.

Components for retaining

We have a line of facings made from electrically welded wire mesh — with inclinations ranging from 65° to 80° — to ensure the exposed face is straight.

Practical tips

On site

System components must be stored well away from machinery, and suitably protected from dust or residues from work on site.

To avoid excessive overlaps and waste, the X-Grid geogrids must be cut to size using a suitable metal stand with metal trestles supporting a circular rod to be inserted inside the roll.

Erosion control components — whether biodegradable or synthetic — must be stored in a dry place and not in direct contact with the natural ground, so as to avoid laying problems later on.

Metal formwork must be stored well away from areas where machinery is operating, and carried in only when it is time to install.

During assembly, it is best to apply U-shaped strips of rubber or metal so that the geogrids can be wrapped correctly over the formwork without getting caught on the top of the bars. (see photo)

Special instructions

We advise against backfilling with silty and clayey material; at the very least, only use this kind of material after mixing it with aggregate.

The full range of system components comes with instructions on the relevant procedures to be followed. Contact us, we’ll be happy to provide case studies and full information.

Join us at Ecomondo 2023

Climate change and extreme natural events are having an impact on the planet’s life balance. The current international focus on the ecological transition and the circular and green economy is making it more and more imperative to make innovative decisions on this front. This is why our TeMa team of engineers and technicians will be attending Ecomondo 2023 to share with professionals, industry, stakeholders, policy makers, opinion leaders and local authorities just how significant a role our products can play in this green drive.

Ecomondo will be held from 7 to 10 November 2023 at Rimini’s exhibition centre. This is the leading international event on the European calendar for sharing and comparing strategies that will shape the EU’s environmental policy. Which is why it’s important to take part.

There’s a well thought out programme packed with conferences, seminars and workshops. Over the four-day show, the programme will tackle interconnected macro issues:

- Bioenergy.

- Circular and regenerative economy.

- Site and land maintenance.

- Waste as a resource.

- The water cycle.

- Environmental control and monitoring.

TeMa champions renewable energy, recycling and sustainable geotechnical projects.

Over our 30 years in the business, and with ever-growing awareness, TeMa has ventured into the realm of sustainability, presenting environmentally friendly solutions for geotechnical projects.

Since our inception, we’ve specialized in reinforced soil solutions for road embankments or ditches, slopes and hillside terracing, landfills and contaminated sites.

No matter what the situation, even in an urban context, there are always green solutions to take the place of concrete. Our catalogue features products that are as high performance as they are sustainable, like biodegradable matting (including pre-seeded mats), geonets and geomembranes. When it comes to handling, there are considerable CO2 savings: there’s no need for gravel, and the soil required is found on site, so no added carbon footprint.

What’s more, our geogrids have earned their reputation as a key substrate in road construction, built to provide lasting strength and withstand cracks or minor subsidence, resulting in a smoother ride and safer road surface.

Join us! We look forward to showing you some of our past projects from around the globe, and some cost-effective and intriguing solutions, such as a horse racing track produced in South Africa built to cope with pounding hooves, even after rain.

We’ll be attending Ecomondo to showcase our solutions, as well as our business decisions:

Part of our products are made using pre-used plastics we “recycle” in our own plants.

We’ve set up two collection and recycling plants (in Russia and Romania) to handle high-density polyethylene, and polypropylene: we sort the waste material, carry out two grinding and washing cycles, and finish with extrusion and filtration.

…we reuse washing water.

wastewater from the washing process is treated and reused for subsequent processes.

…we invest in renewable energy.

Almost 50% of the energy used in our production processes comes from renewable sources: three photovoltaic systems — with rated outputs of 200 kWp, 150 kWp and 100 kWp — and a cogenerator producing another 800 kWp.

Go here for more details.

Join us at the show!

You can find us from 7 to 10 November 2023 on Stand 506, Hall D1, at Rimini’s exhibition centre.

In the meantime, you can find out more about Ecomondo by checking out the official site: click here.

- Published in CORPORATION, Exhibitions and events, news, TeMa Technologies and Materials

TeMa even more transparent about sustainability

With the new EPD certification, TeMa Technologies and Materials provides information about the level of sustainability of its products: this includes most of the membranes and geocomposites manufactured on its production lines. For 30 years, TeMa has regarded environmental protection as a duty and obligation towards the community and future generations.

What is EPD and what is analysed to obtain it?

The Environmental Product Declaration (EPD) is a document that provides specific data on the life cycle of products or a service. It measures the impacts that the production and life phases of a product have on the environment by means of a Life Cycle Assessment to determine the consumption of resources such as water, materials and energy.

It is voluntary and verified by the independent third party SGS so that certified declarations can be given to clients.

International acknowledgement

The EPD document is internationally acknowledged, as it complies with ISO standards. This ensures use, credibility and stability over time, making the data collected available for use in any type of environmental management system and providing information for environmental certification protocols for buildings and infrastructures.

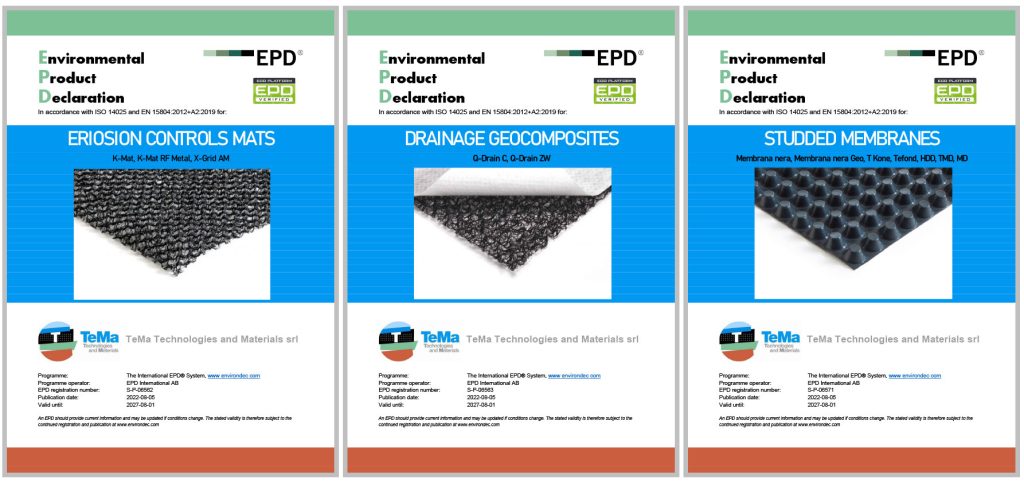

Which product lines from TeMa Building Solutions are EPD certified?

The products having obtained EPD certification are:

- the studded membrane line, which includes Membrana Nera, Membrana Nera Geo, T-Kone, Tefond, HDD, TM and MD;

- the monofilament drainage line comprising Q-Drain C and Q-Drain ZW;

- the anti-erosion and reinforcement geomat line, which includes K-Mat and X-Grid AM.

Our certificates can always be consulted by clicking here and entering TeMa in the filters.

- Published in CORPORATION, news, TeMa Technologies and Materials

We will be at the EuroGeo7 Conference in Warsaw

After being postponed for so many months due to the health emergency, EUROGEO7, the 7th European Geosynthetics Conference will take place at last in Warsaw from 4 to 7 September 2022. We will be participating with our thirty years of experience and our innovative flow of products and functions.

We will be attending with ourTeMa Geo Solutions division, specialized in developing innovative technologies and products for protection, maintenance, retention, reinforcement and drainage in environmental works.

We have achieved these goals because since 1993, when TeMa was established, geosynthetic products have been our targeted approach to geotechnical and environmental applications. At a time when there was little talk of ecosystems, we developed considerable experience in this field, deploying new technologies and finding crucial improvements in terms of durability and less invasive intervention works using geosynthetic products.

The many fields of application range from the most important functions to be addressed in the fields of geotechnical engineering, reinforced earth structures and reinforced soil, to name but a few. They are highly impressive in the fields of hillside agriculture and the urban regeneration of small villages: drainage and filtration for landfills and contaminated sites; roads, railways and other transport applications; rainwater management.

What will TeMa Geo Solutions explore?

The focus is on geosynthetic products and the aspects that make them versatile, high-performance and innovative in geotechnical engineering applications. In particular, we will be focusing on TeMa Geo Solutions technologies for:

- removing seepage water using drainage geocomposites bonded with a nonwoven geotextile;

- reinforcement and stabilization with geogrids;

- the drainage capacity for the cap, bottom and sides of landfills with geonets;

- erosion control and drainage with geomats.

Our technicians will be available to provide catalogues and data sheets with performance details.

To learn more: https://www.temacorporation.com/geo-applications/

- Published in CORPORATION, Exhibitions and events, news, TeMa Technologies and Materials

Proud to be BEE certified

Our strength is that we never stop striving for the best, in everything: we are at the forefront in researching new materials, studying innovative solutions, focusing on the environment and exploiting resources… We couldn’t be any less inclusive.

Our company operates worldwide, we have branches in practically all continents and the concept of ‘internationalisation’ is our daily bread. We have always worked in contact with different people and cultures and have no difficulty in approaching them: it comes naturally to us!

We are therefore delighted to have been awarded BEE certification for our TeMa South Africa division.

What is it and how does it work?

Broad-Based Black Economic Empowerment, or B-BBEE, is a South African government initiative that encourages businesses to integrate more black citizens into all jobs, from employees to entrepreneurs, and reduce inequality in income.

The assessment is made based on 5 parameters:

- Ownership: voting rights and shareholding in the company

- Management control: members in management roles and voting rights with control over the board of directors

- Skills development: learning opportunities for developing new skills

- Enterprise development: support and development of small businesses run by black people

- Socio-economic development: corporate investment in economic and social initiatives.

Each parameter is assigned a value that creates the final percentage score, which is used to assign the category level. There are 8 of them, proceeding in descending order: 1 is the level with the highest score, 8 with the lowest score.

TeMa South Africa has been assessed by the EmpowerBEE certification agency and is a certified collaborator at Level 3 – 110% procurement recognition level.

We aim to improve further in order to reach the highest level.

Click here to find out more.

- Published in CORPORATION, news

Soundproofing the bathroom: Why not?

Having a shower in the middle of the night or at the crack of dawn, flushing the toilet, walking heavily barefoot, dropping bottles, a washing machine spinning, water draining or a jacuzzi in operation. All such activities often take place at times when your neighbours may not want to hear you.

Nothing illegal, but it’s most likely to be very annoying for any neighbours who are sleeping.

Don’t be surprised, there’s a solution to this too: install noise-reducing products in the bathroom.

Where does noise come from?

We are used to thinking that noise is transmitted through the air, but sometimes we forget that walls and pipes also transmit vibrations.

In blocks of flats this is even more amplified, as flats are generally designed in a similar way and systems run in sections between floors: this carries much more noise and rumblings.

Our solution

First and foremost, the ideal solution is to carry out a sound test in order to find out what noise is in that room and design a customised soundproofing system.

Environmental comfort can be taken care of by T-Silence dB21, the panel comprising an internal polymer core bonded with special fabrics on both sides, which reduces noise by 21 dB in a thickness of just 7.5 mm.

T-Silence dB21 is particularly suitable for renovations, as it can be dry-installed without having to a make a new screed (thus saving time, since long drying periods are not required). Furthermore, if not irreparably uneven, the old floor need not be demolished, as T-Silence can be installed over it. It can then be directly cladded with ceramic tile or wooden flooring, or a floating floor system can be installed. If, instead, you decide to remove the existing floor because it’s uneven and then lay T-Silence over the screed, as it is reduced in thickness, it isn’t necessary to intervene on the thresholds between one room and another, as no difference in level will occur.

Beware of acoustic bridges

An acoustic bridge is a critical issue that risks undermining all insulation work. It basically transmits noise and vibration. To prevent this, the joints between T-Silence dB21 panels need to be covered with dB-Strip, the paper adhesive tape impregnated with hot melt adhesive, and dB-Band, the self-adhesive band for perimeter insulation in contact with vertical walls.

Advantages

Insulating the bathroom brings the advantage of enhancing rest and therefore personal well-being.

Moreover, as it is relatively uncommon, it adds value to your property.

- Published in news

The importance of geogrids in reinforced earth structures

In recent years, reinforced earth structures have been particularly popular in projects due to their excellent functional and aesthetic importance in the residential building and public building industries.

Such intervention works achieve the best results by allowing the soil and geosynthetics to “work in synergy”, each one with its own features of ensuring the stability of the work as a whole.

It’s easy to see the high environmental value of such solutions, but let’s take a closer look at the two major factors in reinforced soil works. In this way, we can understand how and why, working together, they lead to amazing results, also in aesthetic terms.

What are reinforced earth structures?

They are structural intervention works in various gradients and dimensions aimed at retention and/or stabilisation. We can identify a few main areas of application:

- Road and railway embankments.

- Restoration and consolidation of collapsed soil on a road.

- Construction of ramps for ascending and descending flyovers.

- Canal or river bank elevations.

- Rockfall barriers.

- Noise barriers along roads or railways.

- Widening of elevated car parks.

- Construction of terracing systems in vineyards.

- Soil consolidation at tunnel entrances.

What are geogrids and why are they often the best solution?

Soil has the intrinsic features of friction and compressive strength, but practically no tensile strength. This is not enough to ensure the stability of a structure.

Major slopes, weather conditions, proximity to embankments, etc. can erode soil, causing landslides and subsidence. For reinforced earth structures, it’s therefore necessary to use geogrids, two-dimensional structures horizontally inserted into soil, which integrate with it without deforming. Their open-mesh structure develops “passive” resistance, thereby increasing the stabilising effect.

This bonding exploits the abilities of the two construction elements, making the entire structure more efficient.

Naturally, the feasibility of retaining works needs to consider:

- the intrinsic characteristics of the soil, such as grain size, the degree of thickening and shear strength, as well as the dilatancy phenomenon;

- the characteristics of the geogrids, such as tensile strength and stiffness, the use of raw materials (polymers) that can also withstand harsh chemical and physical conditions (attacks by chemical agents, soil pH, etc.), and the appropriate geometric structure.

Greening

Eventually, grass will grow and none of the intervention work will be visible: a really attractive and natural reinforced structure. In addition to its aesthetic function, greening also plays an important role in helping the natural friction of soil.

Find out more about our products here.

Experts in finding solutions: a case study

The galloping of horses, the demolishing power of hooves and a high-performance solution. In short, one of our intervention works in Kyalami, Johannesburg, South Africa (2019). This is an equestrian arena where a new moisture management and drainage system had to be designed while ensuring the durability of the work and the well-being of the horses and their hocks.

Horse racing arenas, highly exposed to weather conditions that vary with the seasons and to various training and racing activities that wear out the ground, therefore require constant maintenance. In the past, stone-aggregate layers were used for drainage, which drained rainwater (although not quickly), but had limited resistance to the continuous impact of horse hooves. In order to make the ground more resistant, it was pressed with great force, however, this had a negative effect on the safety of horses. An alternative solution was to preserve the race course as far as possible by reducing its use, i.e. not using it for training but only for competitions.

The solution based on TeMa’s decades of experience in constructing synthetic football pitches allows the construction of race courses for competitions and riding schools that use geosynthetic products. These products improve functionality, reduce intervention times and subsequent maintenance costs, also on a large scale (in our case, the surface area to be covered was 3,000 sq.m).

To find out more, click here.

Innovation in every solution

What do our clients and partners expect? For us to be there when they need us! We have therefore set up an extensive sales network in 80 countries. We rely on trained professionals who interact and meet the needs of very different markets.

We have developed three divisions in specialised areas: residential/commercial works, environmental works and indoor living comfort works. Consequently, the training and updating of our collaborators are the mainstays of our competitive advantage, as are the contributions of Universities and Research Institutes in our R&D area. Innovations arise from focusing on and listening to our clients, who primarily demand interesting and beneficial solutions.

In 2023, our company will be 30 years old, and for almost 30 years we have been harmonising our various sectors and offices to find the perfect balance. Along the way, we could not have imagined what has happened in the last 20 months. The Covid pandemic has upset the strategic balance of supply chains. So, in a world that is speeding up again, we believe that our three-division organisational set-up has helped us to truly meet the specific needs of our clients. Recruiting young people has also raised the potential for an unconventional and truly innovative outlook.

We are known as TeMa, the corporation that meets the needs of clients by operating with the precise intention of not only supplying products but also promptly finding systems and solutions that can solve any problem. This might sound like an easy advertising claim were it not for the fact that this statement encompasses other facets of the “solution maker”, which we intend to be. It is not only a matter of finding answers to problems but also solutions that are less expensive, have less impact on the environment, are quicker to apply, easier, safer and improve durability. And so on.

Such competitiveness matters to designers, builders, installers and distributors in their civil and geotechnical engineering, landscaping, erosion control, transport and soil retention projects with a low environmental impact. For them, we offer high performance to suit all situations, and we do this because we believe in protecting the environment.

- Published in CORPORATION, news, TeMa Technologies and Materials

Embankments in home gardens: small colourful islands

Made of masonry alone, embellished with different types and colours of plants and flowers, and of varying heights, embankments are often part of public buildings in parks and squares, but also a distinctive feature of private gardens. In the urban construction context, embankments can be borders for roadside verges, steps and flowerbeds, reaching a relatively low height, almost always less than 1 metre.

The provide a very attractive and organised visual effect and can be customised with the colours and types of plants you prefer. However, in order to achieve adequate stability for such intervention work, regulations require certain specifications to bear in mind for their construction.

A short and simple recap: let’s start by understanding what they are and how they are built.

What are embankments?

Embankments are accumulations of earth that form more or less evident differences in the level of the ground and can be natural or artificial. Natural embankments are caused and possibly accentuated by landslides, whereas artificial ones are man-made and consist of an earth fill supported by a wall, often in order to highlight the difference in level.

The risk of landslides

As mounds of earth, especially if they are of a certain height, embankments can be severely tested by atmospheric events, resulting in erosion and runoff due to rainwater.

Various characteristic elements can therefore be recognised:

- drainage and runoff systems in the underlying area where all rainwater accumulates;

- support and reinforcement of slopes, the part most susceptible to erosion;

- substrates and erosion control systems to allow plants to grow in the best conditions by sheltering the topsoil from the effects of the wind, sun and rain until the plants have become strong and well-rooted.

Block retaining walls and reinforcement grids

In order to prevent soil erosion or irrigation, embankments are reinforced with retaining walls in a combination of concrete blocks and geogrids, which meet geotechnical, building and architectural requirements.

TeMa Geo Solutions has the right products to create this type of construction.

For soil reinforcement we suggest X-Grid, reinforcement geogrids, which are knitted uniaxial geogrids made of high tenacity polyester yarns covered with a protective PVC layer.

For retaining walls, the range includes T-Block, a single concrete block for building reinforced walls.

The special feature of this product is the male/female joint, shaped directly on the block. This ensures maximum connection between the blocks, thus avoiding the use of mechanical fasteners, glue or mortar and making the wall stronger and more resistant to damage.

Find here all the specifications of the products mentioned.