Damp, rising damp and efflorescence in basements.

Damp, mould, stains and flaky plaster in basements are a homeowner’s worst nightmare. We’ve mentioned numerous times that weather events and groundwater, where not controlled properly, are the main cause of damp. Of course, it doesn’t just affect the walls, but the whole structure, including flooring, on the basement level or even on the ground floor.

The phenomenon that’s so often underestimated is so-called “rising damp”, which occurs when water under the ground enters walls as a result of direct contact and is pushed upwards by capillary action, allowing the moisture to rise around ten centimetres or more. The moisture can even climb metres up the wall by “latching on” to molecules of a different kind, in this case those of the actual walls. The damage caused by the abnormal increase in moisture inside walls is immediately visible on the walls of ground-floor rooms or basements.

What effects the water’s capillary action has

The effect of capillary absorption manifests in the form of:

- static damage to the building, which is weakened and becomes less safe

- worsening occupant comfort as a result of unhealthy, smelly rooms

- cosmetic damage, with the appearance of stains and peeling plaster

- higher heating costs due to the lower surface temperatures of internal walls

- efflorescence

- a capillary action that causes water to rise through walls, bringing with it salts from the ground that, once they crystallize as a result of the evaporation process, swell and cause paint and plaster to peel: white stains forming around cracks are known as salt efflorescence.

The effects are less visible when the surface affected is flooring, with symptoms like swelling, salt efflorescence, mould or changes in the colour of grout often only appearing later on.

All these issues derive from the misguided choice of materials, or poorly designed and executed work, often compounded by the fact that the foundations’ waterproofing is damaged or even non-existent. This is not an issue linked to weather events, rather it stems from the presence of groundwater.

How TeMa Building Solutions can help

Both rising damp and efflorescence issues can be prevented with the use of suitable materials. TeMa Building Solutions offers an extensive range of studded membranes and drainage geocomposites to remove water before it comes into contact with the structure and to provide waterproofing with reliable, lasting protection.

Our engineers are here to help you choose the right specific product for your next project.

Contact us!

- Published in BUILDING, Drainage geocomposites, Foundation and underground structures, Foundation and underground structures - Damp proofing systems, Foundation and underground structures - Drainage systems, Foundation and underground structures - Systems for mechanical protection, Foundation and underground structures - Systems for Waterproofing

Tips for the correct laying of TMD 1011

For vertical applications, such as foundation walls, and for horizontal applications, such as flat roofs, mechanical protection of waterproofing is required and, often, also drainage: TMD 1011 is a studded membrane, produced by TeMa Building Solutions, that performs both functions: drainage for vertical applications and waterproofing protection for horizontal applications.

A few tips for laying TMD 1011 on horizontal surfaces

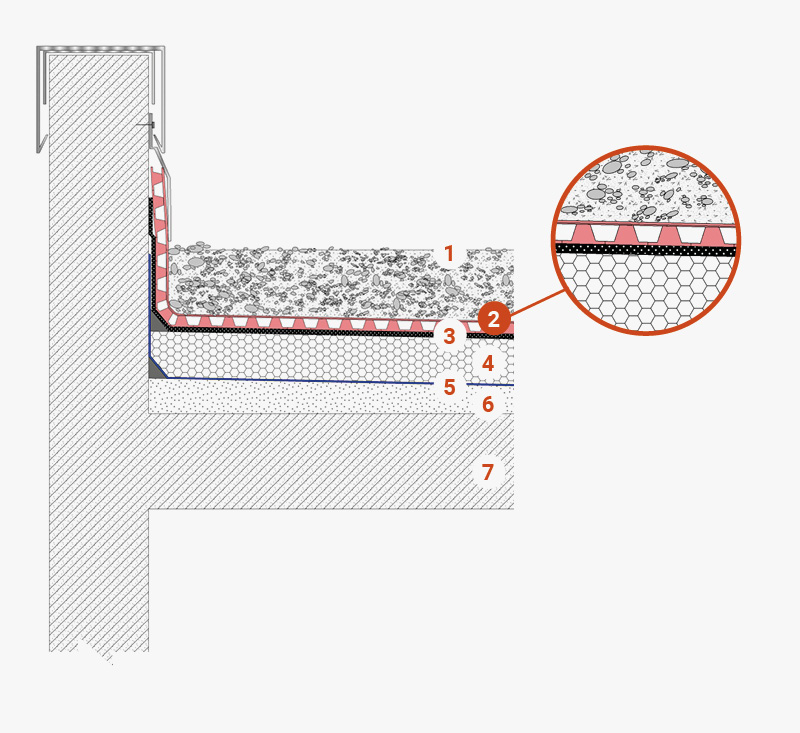

Flat roof with gravel finish (weighted)

1 Gravel finish

2 TMD 1011 membrane serving as a drainage layer and for waterproofing protection

3 Waterproofing membrane

4 Thermal and acoustic insulation

5 Vapour barrier

6 Sloping underlayment

7 Load-bearing structure

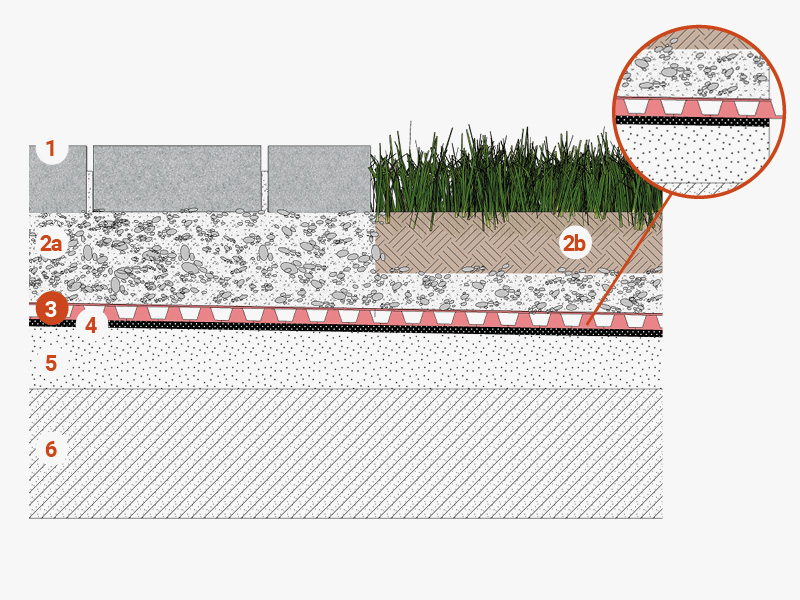

Walkways and green areas

Walkways and green areas

1 Interlocking block paving

2a Crushed stone bedding course

2b Growing medium

3 TMD 1011 membrane serving as a drainage layer and for waterproofing protection

4 Waterproofing membrane

5 Vapour barrier

6 Sloping underlayment

7 Load-bearing structure

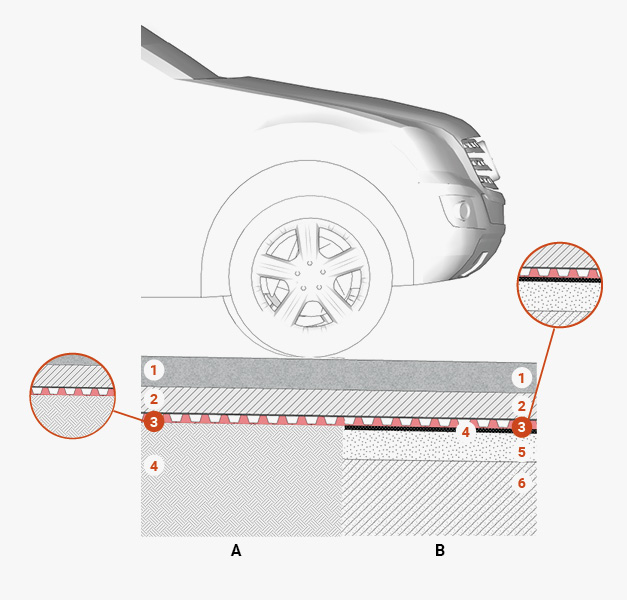

Surfaces suitable for vehicle traffic A

1 Paving designed to take vehicle loads

2 Sand bedding layer

3 TMD 1011 membrane serving as a:

– drainage layer

– substrate in place of traditional concrete levelling compounds

– separating and leachate containment layer (oils or hydrocarbons)

4 Substructure / ground

Surfaces suitable for vehicle traffic B

1 Paving designed to take vehicle loads

2 Sand bedding layer

3 TMD 1011 membrane serving as a drainage layer and for waterproofing protection

4 Waterproofing membrane

5 Sloping underlayment

6 Load-bearing structure

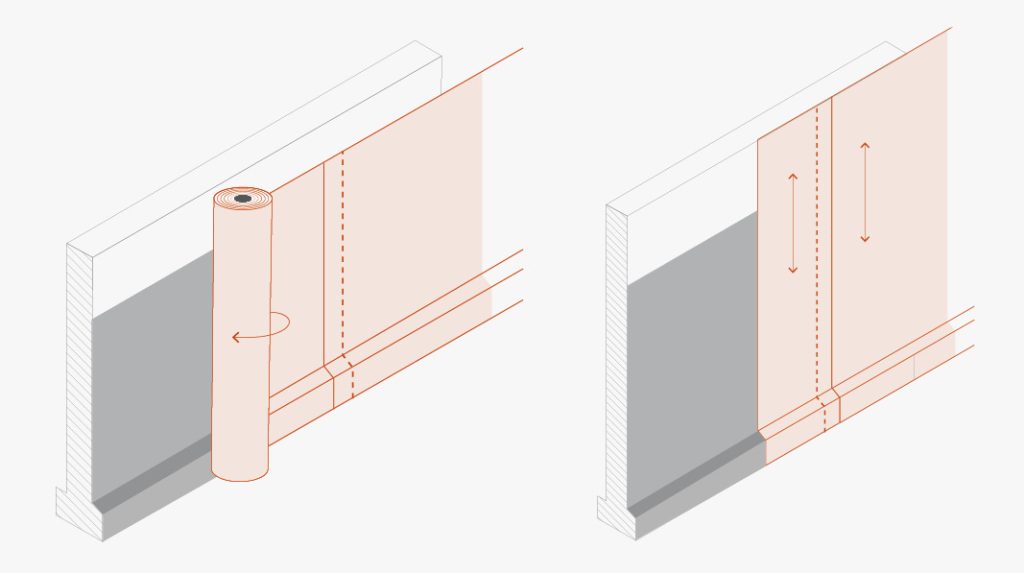

A few tips for laying TMD 1011 on vertical surfaces

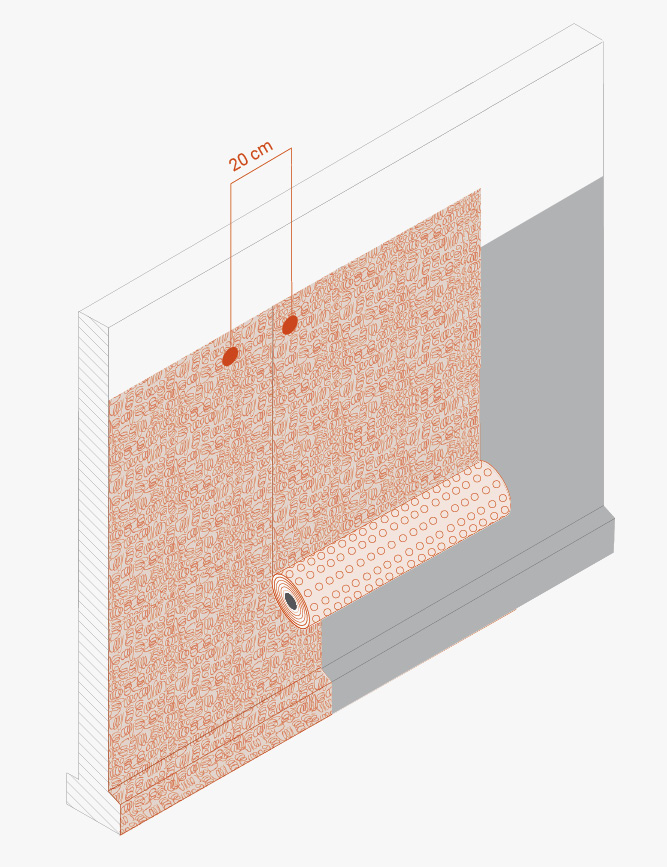

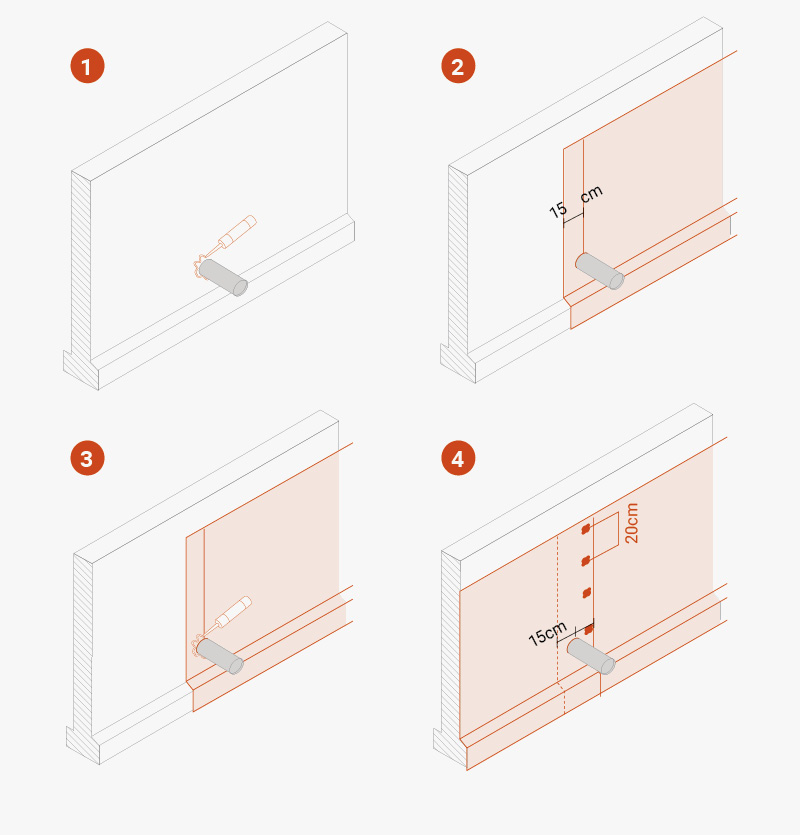

Unroll the membrane and install it vertically or horizontally: in the latter case, the width of the roll corresponds to the height of the wall to be protected. Two consecutive membranes should overlap by about 20 cm, and the studs should interlock.

For horizontal joints, if the TMD 1011 membrane is not wide enough to completely cover the height of the installation, the first layer should be installed from the base upwards and then, keeping an overlap of at least 15 cm, the second layer should be installed by overlapping the first layer outwards (i.e. towards the side away from the wall). Install washers every 20 cm in the overlapping area.

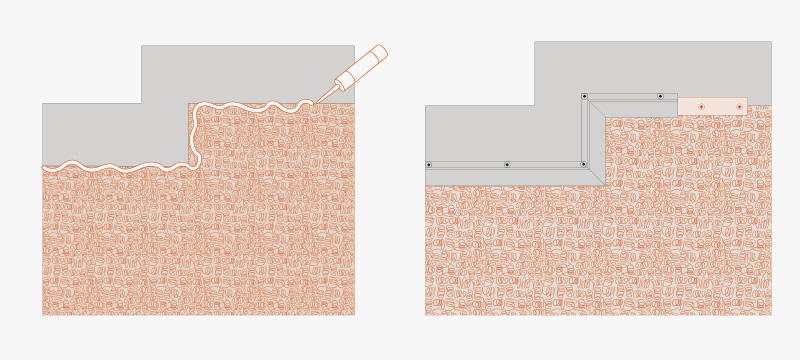

Inlets for utility connections, such as water, gas, sewers or similar pipelines

- Place mastic sealant around the pipeline or inlet.

- Cut the TMD 1011 membrane vertically so that it extends 15 cm beyond the pipeline or inlet, trimming the membrane so that it adheres as tightly as possible.

- Put mastic sealant on the membrane so that there is a layer of mastic both above and below the membrane around the pipeline or inlet.

- Start the next installation of the membrane 15 cm before the pipeline or inlet so that the overlap around the pipeline or inlet is 30 cm. Trim again around the pipeline or inlet for watertightness.

- Install fasteners every 20 cm along the edge of the overlapping membrane.

Change of level or areas where the smooth part has been trimmed

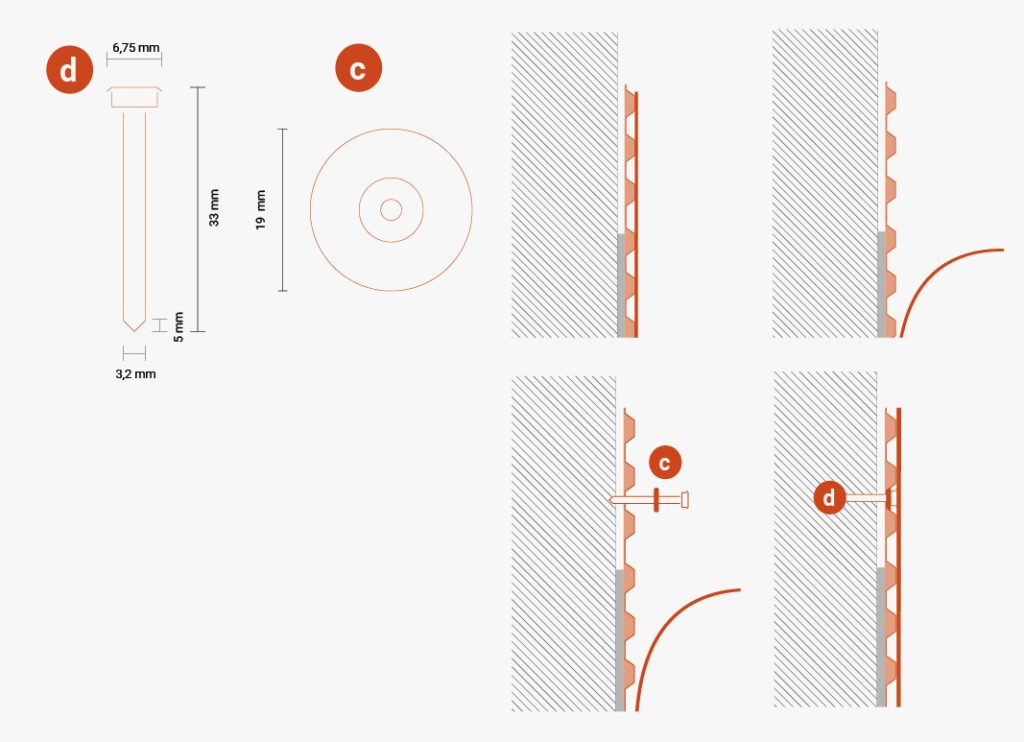

Use T-Profile + T-Nails to seal the edge, using a sealant for the area to ensure that the edge is properly sealed.

TMD 1011 should also be protected with T-Profile to prevent soil from penetrating into the gap between the wall and membrane. Then, fasten it using washers and nails with T-Nails spaced at intervals of 20-30 cm, either along the upper edge of the studded membrane or along the profile.

Drainage for diaphragms and berlin walls: a practical and safe solution

Some of the most widely used works in the civil engineering field are diaphragms and berlin walls, which counteract strong thrusts of the soil and prevent landslides and structural subsidence.

Diaphragms are supporting walls consisting of pointed vertical elements (piles) or continuous elements (walls) made of steel or reinforced concrete. They are driven into the ground to a considerable depth, whereas Berlin walls are flexible retaining structures constructed with vertical micro-piles.

Both solutions are used where it’s impossible to construct excavation walls of an adequate gradient due to the presence of other nearby structures and to the morphology of the area , which imposes limited work spaces (that would make manoeuvring large machinery impossible).

Berlin walls made of micro-piles are one of the most popular applications on construction sites for implementing waterproof retaining works. The technique allows work to be carried out on almost all types of terrain, especially when it’s necessary to use on-site systems that are smaller than in the past.

Since works are in contact with the ground, the drainage aspect should not be underestimated. If rainwater and groundwater exert pressure on the vertical wall, they may damage the waterproofing. TeMa Building Solutions therefore has the right product for this application: T-Mix Drain WP, the geocomposite that not only drains but also provides the functions of filtration, separation and stay-in-place formwork.

TeMa has acquired considerable experience with geocomposites. For many years, the company has been providing this system to replace the conventional gravel drainage system. The results are long-lasting and it’s the ideal solution: compared to conventional gravel, it’s less bulky, easily transported and quick to install. This reduces the costs of transport and implementation and on-site construction time while, last but not least, resulting in considerable savings in terms of CO2.

Fields of application

As mentioned above, diaphragms and berlin walls are widely used where space is limited. More specifically, they can be used in the construction industry, for example for underground garages in homes or commercial premises, for basements. They can also be used in river works, such as quays and piers for boats, or in earth dams and wells.

Having the experience of TeMa technicians and tested effective products such as T-Mix Drain WP at your disposal is therefore a guarantee for your construction site.

Can’t go up? Let’s make space below!

Nowadays, certain solutions allow you to create perfectly liveable and comfortable basements.

Of course, existing little-used basements can also be renovated, but you need to take some constructive measures to ensure that the building is in good condition and the environment is healthy.

So let’s see what we need to focus on.

Damp and moisture seepage

Basements are in direct contact with the ground, both the floor and the vertical walls.

Rainwater or ground moisture can penetrate concrete, leading to marks and mould that may cause the wall to peel. The aesthetic damage is as serious as the structural damage: mould is anything but healthy!

It therefore becomes necessary to provide a separation barrier between the structure and the ground that performs the function of damp-proofing, i.e. controlling moisture in the absence of hydrostatic pressure (click here to read more).

TeMa Building Solutions suggests T-Bentostop, in the F and F XL versions, a geocomposite, which attaches to concrete and consists of natural sodium bentonite with a waterproofing function, and T-Kone, the HDPE studded membrane available in several versions.

![]()

Drainage

Groundwater or dispersed water may flow in the ground, even near structures, therefore increasing the load on walls. So, it is essential to drain water and prevent it from entering by reducing the hydrostatic pressure on surfaces: T-Kone G Drain, T-Net Drain studded membranes and the drainage geocomposites in the T-Mix Drain range perform this function while keeping walls dry.

![]()

Mechanical protection of waterproofing

The vertical walls of basement rooms have to withstand heavy loads exerted by the ground. It is therefore essential to provide systems to protect the waterproof layer in order to guarantee the safety and long life of the building.

The T-Kone, T-Kone Star and TMD (also in the Plus version) range are studded membranes specifically designed for foundations and underground structures: their high load-bearing capacity makes them ideal for such applications.

![]()

Aeration

To keep masonry dry and allow constant and substantial air circulation, studded membranes can be installed with the studs facing inwards. In this way, their raised shape creates aeration channels that allow the wall to literally “breathe”.

Ideas for renovating your basement

It has been estimated that the value of your property increases by about a third if you have a well-planned basement. An extra room is always very useful and its intended use may vary greatly.

You can opt for a studio for working from home, a spacious laundry room for hanging up your washing, a playroom for your children, a relaxation area, a rehearsal room for talented home musicians, or even a free space for hosting friends, a wine cellar for preserving the best bottles with a tasting area, a gym or a personal home cinema.

- Published in BUILDING, Drainage geocomposites, Foundation and underground structures, Foundation and underground structures - Damp proofing systems, Foundation and underground structures - Drainage systems, Foundation and underground structures - Systems for mechanical protection, Foundation and underground structures - Systems for Waterproofing, Studded membranes and accessories

The importance of studded membranes

Research conducted in the building market has found that most construction disputes are due to damage caused by water and damp seeping into retaining structures.

Protecting foundations

In order to avoid inconveniences of this magnitude that are discovered in the course of time, designers and installers undertake to protect foundations. TeMa has therefore developed products and systems that protect waterproofing during backfilling operations, thus guaranteeing the stability of intervention work over time. For practical purposes, we propose two types of fairly common intervention works in civil engineering by showing you how two of our studded membranes work.

Retaining walls

Retaining walls are intervention works that have the main purpose of retaining slopes or soil embankments during works such as the construction of roads below ground level. Various types of wall can be built: in masonry or reinforced concrete, or using precast concrete elements.

Whichever solution is used, you always need to consider and comply with specific hydrogeological features: TeMa laboratories offer a range of membranes that meet such requirements, whereas technicians and installers can assist in choosing the best solution to use.

Mechanical protection of waterproofing

For the mechanical protection of waterproofing you can choose T-Kone, which also performs a damp-proofing and drainage function. Damp proofing creates a physical barrier between the structure and damp soil and avoids any possible damage to the waterproofing membrane, both during onsite operations and soil settlement.

The T-Kone family is part of a range of bare HDPE studded membranes (such as T-Kone S). Alternatively, these membranes can be bonded with a geotextile such as T-Kone G Drain or with a geotextile and a damp-proofing element such as T-Kone G Drain Plus.

Diaphragms and berlin walls

Suppose we need to work in an urban context doing underground intervention work. First of all, we must guarantee the stability of the structures surrounding the area to be excavated.

Diaphragms and berlin walls are used in situations where it is impossible to create excavation walls with an appropriate slope to prevent landslides or structural subsidence. In the form of steel/ reinforced concrete piles or walls, they are driven deep into the ground and coupled with TeMa membranes, which provide damp-proofing, mechanical protection or drainage functions.

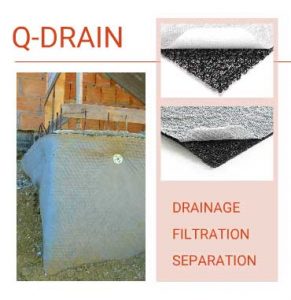

Damp-proofing, mechanical protection or drainage functions

For this purpose, products such as Q-Drain can be used, which have a polypropylene monofilament drainage core bonded with one or two non-woven geotextiles, also made of polypropylene. These filter water and adapt to the conformation of the ground, thus guaranteeing stability.

These are just some of the membranes we are able to supply. Find out which one is best for you and assess the best solution with our team of experts. TeMa will assist you throughout each phase of the design process.

To discover TeMa products, visit the website.

- Published in BUILDING, Foundation and underground structures - Damp proofing systems, Foundation and underground structures - Drainage systems, Foundation and underground structures - Systems for mechanical protection, Foundation and underground structures - Systems for Waterproofing, Retaining walls, Retaining walls elements, Studded membranes and accessories

For elevators… That are tested!

Just imagine the face of those present when Elisha Otis, a smart American entrepreneur, presented the first elevator in 1853. It was enlightening! During an exhibition at Crystal Palace in New York, visitors were shown how the enclosure works, which was fitted with an automatic safety device for blocking it in the event of an emergency.

Today, however, we are used to using elevators and we often complain if they are out of order and we have to go back to the old-fashioned habit of using the stairs!

But what does building an elevator involve?

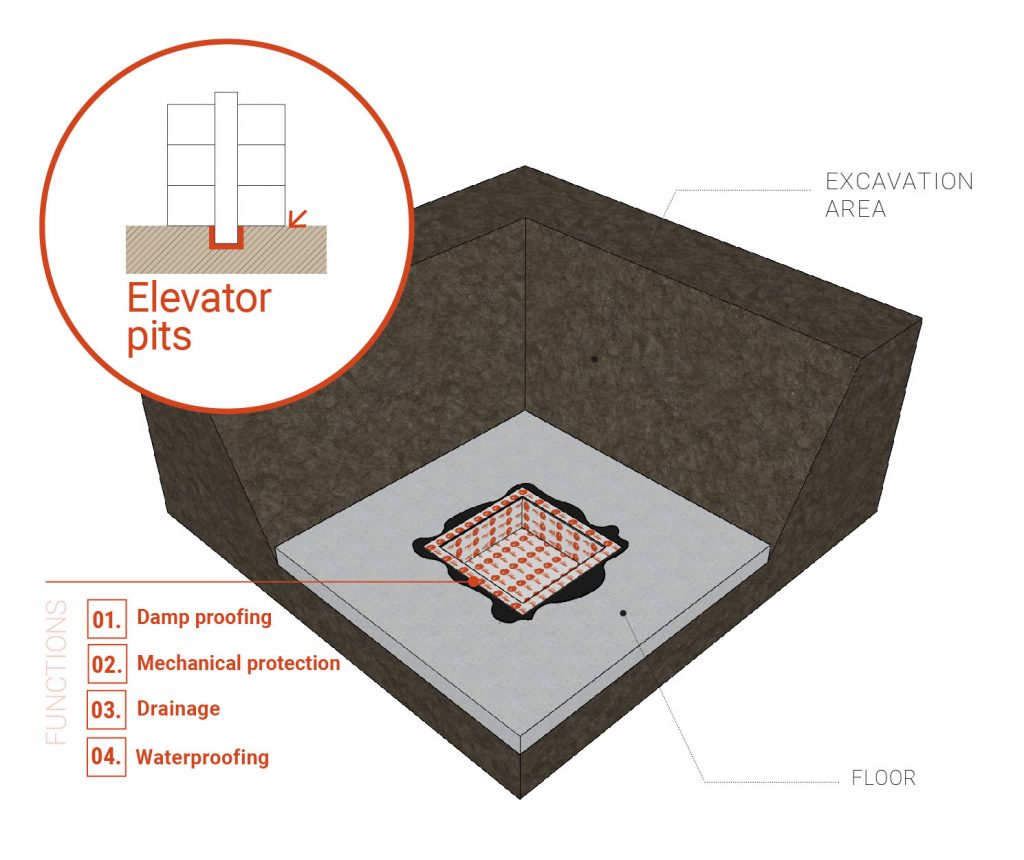

Elevator pits are structures located at a lower level than the internal standing area and must be able to withstand both static and dynamic loads. In short, they need to not only support the weight of your Saturday shopping but also take it up to the fifth floor!

Many problems may be encountered when an elevator is being installed. First of all, there is the danger of infiltration and all the consequences it may bring. Then we mustn’t underestimate the fact that, in the case of a hydraulic elevator, oil may leak from the system, which is why electric elevators are always recommended. TeMa has developed the T-Kone family: HDPE honeycomb membranes that provide mechanical protection, damp proofing and drainage. As far as drainage is concerned, the research and development centre that TeMa relies on has developed drainage geocomposites that filter, protect and drain the system.

Waterproofing? Yes, but how

It is not enough to install membranes that perform a drainage function, it is also necessary to make spaces waterproof. But how? By using bentonite geocomposites that self-bond to concrete, such as T-Bentostop F and T-Bentostop F XL. They are made of a non-woven fabric and a polypropylene fabric with a layer of natural sodium bentonite in between.

These are the essential aspects that should never be underestimated for excellent, high-performance implementation. We must always remember that a thorough preventive analysis of the dangers, along with accurate and responsible installation, are the best techniques for avoiding problems and inconveniences caused by infiltration in the future.

Find out more about damp proofing, drainage, mechanical protection and waterproofing systems of TeMa Building.

- Published in BUILDING, Drainage geocomposites, Foundation and underground structures, Foundation and underground structures - Damp proofing systems, Foundation and underground structures - Drainage systems, Foundation and underground structures - Systems for mechanical protection, Foundation and underground structures - Systems for Waterproofing