Dry Renovation: a Quick and Clean Method

At an historic moment in time when everything is coming to a halt, we must not forget that we still have ways to increase our knowledge and get ready for the time when everything gets back to normal. The home, for obvious reasons, is now the focus of our thoughts. The more days go by, the more we notice some jobs that have been left aside for too long: a basement to be fixed, a wall to be better insulated or a terrace floor to be changed because it is excessively damaged. So let’s discover something more about one of the ways to renovate those parts of the home that require our attention.

Dry renovation: a valid solution

The dry renovation system is a processing method that does not involve the use of water, adhesives or sealants that need to remain in place to dry. Although Italy has always opted for the so-called wet clay-cement system, this does not mean that new methods have not recently been explored. This traditional work method was cast aside during the years of crisis in Italy in the building industry, since it focused on protecting the existing heritage and, therefore, on renovating rather than building from scratch.

Renovating, synonymous with saving

After all, renovating becomes synonymous with energy efficiency. You save on your bills and gain in terms of wellbeing and living comfort, primarily by enhancing the value of your property. The dry installation system, which can be applied to the outside of a building, to its structure or to its internal system, offers many advantages.

We talk about the eco-sustainability of new materials, because they can be recycled, replaced if damage or deterioration occurs, and even re-used. Moreover, dry renovation allows much quicker intervention times and more sustainable situations because tenants do not need to leave their homes during intervention works.

The materials and method used by TeMa

In the specific context of TeMa Interior, the division dedicated to floors, balconies and terraces, soundproofing and waterproofing membranes are used that are easily shaped and transported because of their minimal weight.

Combined with dry installation, these materials allow short intervention times and greatly reduced costs. But remember that this does not entail any reduction in the performance of the intervention work. The final cost of any intervention will be lower because the thickness of the membranes is reduced and, consequently, the quantity of the materials used.

It is precisely the materials, with their physical properties and excellent performance, that ensure the efficiency of intervention work, first and foremost by facilitating the procedures involved.

To find out about all our applications, visit our website.

- Published in Acoustic insulation system - under tile, Indoor and outdoor floor coverings, INTERIOR, Uncoupling membrane, Waterproofing system with membranes

Cycle/pedestrian paths: when we get back onto our saddle, we’ll know more about them…

We know that our bike has become a mirage. But we can promise ourselves to use it more when this period of seclusion is over. Meanwhile, why don’t we take advantage of the time available to discover interesting things all around us? For example, cycle paths. Let’s start at the beginning.

What is the correct definition of a cycle/pedestrian path?

It’s where you can ride your bike, of course. But, can pedestrians walk on it too? What is the direction of movement? Then there are increasingly more complex questions, such as: has it been built as a separate cycle path or as a reserved lane? Is it a cycle/pedestrian path or a vehicular/cycle path? In short, there are many features that a cycle/pedestrian path must have in order to be defined as such. Let’s take a look at them together.

The cycle/pedestrian path was invented to allow pedestrians and bikes to get about. Such paths require cyclists to respect pedestrians and get off their bike whenever necessary to avoid getting in the way. Consequently, they are not paths for the exclusive use of cyclists.

Creating these kinds of paths encourages people to get about without using a car, thanks to these dedicated spaces, where they can feel safe from urban traffic.

How do you build a cycle/pedestrian path?

In 2018 TeMa Geo Solutions built a cycle/pedestrian path in Cozzuolo di Vittorio Veneto (TV). One of the main aims of the project was to improve road safety in an area that is a gateway to the city and where a city park is situated, used by families and children.

First of all, we enlarged the road and the nearby roundabout in order to create the necessary space for inserting the path. The enlargement was facilitated by the construction of a reinforced earth escarpment, for which reinforced geogrids were used. Installed in the ground, they create friction and enable the system to withstand significant levels of stress. The intervention work, designed on the basis of a single berm positioned at about 2 metres above ground level, allowed pedestrian and cycle traffic in an area that had been dangerous from the outset.

Looking on the bright side, when you get back onto your saddle, you’ll be more aware of what’s under your wheels. Enter the TeMa world, visit our website.

TeMa: a support for the ground

Geo Solutions is the TeMa division that has been developing technologies and products for protection, maintenance and drainage in the field of major environmental works for over twenty years.

A SPECIAL FOCUS ON THE TERRITORY

More specifically, due to the location of its first production unit – situated near the hills that are now a UNESCO World Heritage Site – TeMa has always kept an eye on agricultural lands and especially wine-producing landscapes, which are now gaining increasing attention because of their economic importance and their environmental value.

This new focus on the landscape, including the agricultural one, has never been as relevant as now. We have officially entered the green year and therefore, today, we want to show you some systems for preserving your wine crops.

THE MAIN RISKS: EROSION AND DRAINAGE

The main risks that undermine the stability of the soil include: the natural erosion of the topsoil with the resulting need to reinforce it and the problem of water drainage.

EROSION: CAUSES AND SOLUTIONS

Soil erosion is caused by rainwater runoff, which, by removing the top layer of the soil, can cause significant erosion in the long term.

Various applications are available that provide protection against soil erosion. TeMa proposes natural and synthetic solutions, depending on the circumstances: a 100% natural jute fibre bionet can be used, or a three-dimensional PP geomat, such as KMat. A system of geosynthetic reinforcements (woven geotextiles or geogrids), once embedded in the subsoil, recreates a tensional layer that absorbs any stress of greater intensity than the soil.

DRAINAGE: CONSEQUENCES AND SOLUTIONS

Finally, to solve the fundamental cause of soil instability, namely drainage, TeMa has developed drainage trenches capable of removing water that is naturally absorbed by the ground. These are trench excavations, usually rectangular in section, filled with natural inert material, such as gravel or broken stones from quarries, with a high degree of permeability. Removal takes place either through the trench filling material or through the drainage pipe located at the base of the trench. To avoid another possible problem, i.e. clogging of the pipe, it is entirely covered with layers of non-woven fabric.

WHY CHOOSE TeMa?

Its attention to details, to small things, sets one company apart from all others. This is why TeMa stands out in its sector, thanks to its drive towards innovation and its respect for the environment, whose landscapes are unchanged after intervention works by TeMa.

Find out more, explore the TeMa website.

- Published in GEO, Landfills, news, Research and development, Synthetic turf soccer fields - Accessories

Multiple interventions… Mainly in the private sector

In 2018, we were called to a private house in Pordenone. As a result of sudden and severe meteorological events, the escarpment behind a reinforced concrete retaining wall collapsed. We were quick to intervene to avoid any kind of damage, since the house was under construction and the environmental impact had to be almost minimal.

SOLUTION ADOPETD

We therefore decided to use our PET-PVC 55 XGrid, the uniaxial woven PET geogrid that provides new stability for soil. It is a reinforcement geogrid made of polyester synthetic yarns, obtained by weaving, which is highly resistant and coated with a protective layer (PVC). Uniaxial PET-PVC XGrids are used to implement soil reinforcement support works, whereas biaxial XGrids are used for soil reinforcement and stabilisation.

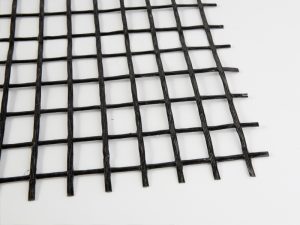

Uniaxial PET-PVC XGrid

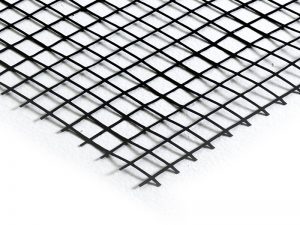

Biaxial PET-PVC XGrid

TeMa GEOSYNTHETICS

TeMa Geo Solution has the mission of intervening on the environment using geosynthetic products and the lowest possible impact. This goal is pursued by researching and inventing new products for environmental engineering, actively involving planners and companies while assisting customers in the pre-sale phase and during and after installation.

Thanks to a modern integrated production system with branches in Italy, Spain, Turkey, Russia, Romania and the USA and a widespread sales network in more than 60 countries, TeMa offers tailor-made solutions for all projects involving structural, protection, maintenance and safety elements in the residential and civil building sectors and in the field of major environmental works. Furthermore, TeMa is not only involved in the industrial building field but also in the private building one.

This is just one of many stories we could tell you about our company, which focuses on technological innovation, ongoing research and territorial responsibility.

For elevators… That are tested!

Just imagine the face of those present when Elisha Otis, a smart American entrepreneur, presented the first elevator in 1853. It was enlightening! During an exhibition at Crystal Palace in New York, visitors were shown how the enclosure works, which was fitted with an automatic safety device for blocking it in the event of an emergency.

Today, however, we are used to using elevators and we often complain if they are out of order and we have to go back to the old-fashioned habit of using the stairs!

But what does building an elevator involve?

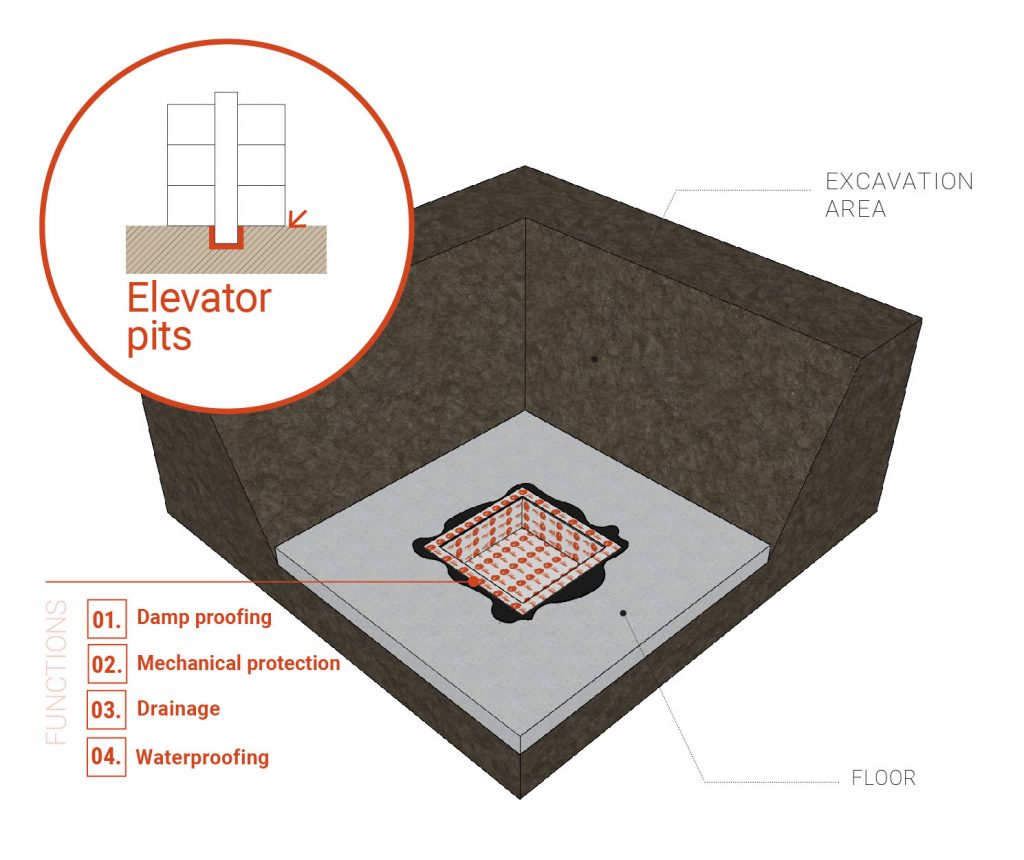

Elevator pits are structures located at a lower level than the internal standing area and must be able to withstand both static and dynamic loads. In short, they need to not only support the weight of your Saturday shopping but also take it up to the fifth floor!

Many problems may be encountered when an elevator is being installed. First of all, there is the danger of infiltration and all the consequences it may bring. Then we mustn’t underestimate the fact that, in the case of a hydraulic elevator, oil may leak from the system, which is why electric elevators are always recommended. TeMa has developed the T-Kone family: HDPE honeycomb membranes that provide mechanical protection, damp proofing and drainage. As far as drainage is concerned, the research and development centre that TeMa relies on has developed drainage geocomposites that filter, protect and drain the system.

Waterproofing? Yes, but how

It is not enough to install membranes that perform a drainage function, it is also necessary to make spaces waterproof. But how? By using bentonite geocomposites that self-bond to concrete, such as T-Bentostop F and T-Bentostop F XL. They are made of a non-woven fabric and a polypropylene fabric with a layer of natural sodium bentonite in between.

These are the essential aspects that should never be underestimated for excellent, high-performance implementation. We must always remember that a thorough preventive analysis of the dangers, along with accurate and responsible installation, are the best techniques for avoiding problems and inconveniences caused by infiltration in the future.

Find out more about damp proofing, drainage, mechanical protection and waterproofing systems of TeMa Building.

- Published in BUILDING, Drainage geocomposites, Foundation and underground structures, Foundation and underground structures - Damp proofing systems, Foundation and underground structures - Drainage systems, Foundation and underground structures - Systems for mechanical protection, Foundation and underground structures - Systems for Waterproofing

Successful collaboration

In all three of its divisions, TeMa has an in-company technical department that supports and assists its customers in the various phases of implementing a project. We take care of all the details, from choosing the solution to using the method of installation.

At TeMa, our technicians use in-depth analysis and cutting-edge software to propose effective, complete and reliable solutions for any type of intervention in the field of geosynthetic products. The dimensional evaluation, structural checks and specifications of the products to be used are of considerable support for the planner or the contractor. But that’s not all. The same is also true for the most experienced operators in the sector who feel the need to expand their knowledge, gaining experience in a constantly developing field. And the outcome? Being able to propose versatile solutions in step with technologies.

The companies in the IWIS Group, including TeMa, have implemented their production plants using innovative technologies, investing in a system that ensures that soil, air and water are protected. We have three photovoltaic plants, 200 kWp, 150 kWp and 100 kWp, which allow us to use energy obtained from renewable sources. The holding company also uses recycled materials for some of its production processes, relying on 4 specific plants for recycling plastics.

TeMa Geo has the support of a research laboratory, among other things, since the company firmly believes that only constant commitment to researching and developing new solutions is the key to success and constant improvement. Collaboration between the technical office and the testing and quality laboratory, especially in the geosynthetics sector, is fundamental: it gives the company’s customers state-of-the-art solutions with researched and tested products while supporting planners and contractors with the correct installation of the proposed solutions. Tests of durability, compressive strength and drainage capacity in the most critical situations are just some of the tests that TeMa laboratories carry out daily to ensure that its products meet the strict pre-established quality standards. The fact that these products are natural and/or recycled guarantees that they are not harmful to the environment, confirming TeMa’s commitment to environmental protection.

It is precisely this continuous pursuit of excellence that has allowed TeMa to obtain UNI EN ISO 9001:2000 certification, which acknowledges a quality system with the highest levels of performance. Moreover, in compliance with the CPD (Construction Product Directive) 89/106/EEC, the product ranges proposed by TeMa have followed the procedure to obtain the CE mark.

Find out more about TeMa Geo Solutions products.

- Published in CORPORATION, GEO, Research and development

A new wellbeing range

As humans, one of our basic needs is to create a nest that is warm and dry, and protected from bad weather conditions, hoping that a woodpecker will not come along and live above this nest. Unfortunately, we do not always realise that what affects people’s wellbeing is not only the pleasure of the warmth that an isolated environment brings, but also the silence.

Silence has only recently been re-evaluated as a category

Silence has only recently been re-evaluated as a category of wellbeing. Modern culture has allowed it to be acknowledged as a pre-requisite for a peaceful life. The concept of health has extended its boundaries to include other areas such as noise, which, together with other factors such as light and temperature, influences people’s good living. The World Health Organization (WHO) defines the concept of health as “a state of complete physical, mental and social wellbeing and not merely the absence of disease or infirmity.” Enjoying good sound insulation in the home is therefore not an extra but a necessity. This is why TeMa Interior decided to create T-Silence to reduce footfall noise.

T-Silence, a universally valid option

To make T-Silence a universally valid option, Tema decided to use materials with narrow thicknesses, minimally invasive intervention methods and reduced on-site installation times. In this way, those who are building from scratch or renovating and those who already live in a building and cannot leave it temporarily can make use of the system. Dry applications are used that do not require new screeds and therefore a drying cycle is not necessary. A further advantage not to be overlooked is the option of applying T-Silence without demolishing the existing floor and/or the screed below. This avoids any inconvenience for tenants and ensures quick installation.

So, what is the advantage of soundproofing your home? You can achieve your own wellbeing.

Silence will accompany your daily routine, aiding concentration and avoiding any change in your mindset that normally leads to anxiety, depression and discontent. In the evenings, you will have no problem falling asleep, you will not be woken up in the middle of the night by noisy neighbours and you will allow your brain to re-work the stimuli collected during the day and peacefully fix your memories. Sleep considerably affects everyone’s ability to concentrate and promotes growth processes, which is why it should not be underestimated.

This is why a system like T-Silence becomes essential: because it preserves, protects and enhances your wellbeing. Spread the word and tell the neighbours above you and think about those below you.

If you want to learn more and discover the T-Silence application methods, browse the CATALOGUE.

Restore walls with T-Kone Plaster

The appearance of damp on walls may be due to various possible causes. The most common include the absence of waterproofing systems in the external part of the wall, the one in contact with the foundation soil, the absence of any efficient mechanical protection that may cause damage to the waterproofing system, or the presence of air saturated with moisture – due to inadequate ventilation – that comes into contact with cold masonry and is, therefore, not thermally insulated.

All this may cause a series of phenomena such as the appearance of whitish areas on walls. These are more frequently known as “efflorescence” and are caused by the build-up of salts, which may lead to the detachment of the surface plaster.

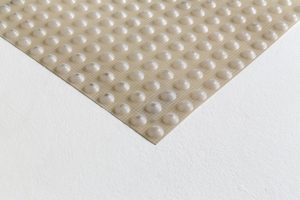

However, walls cannot always be restored from the outside. To solve this problem of an unhealthy environment, TeMa Building recommends T-Kone Plaster, a studded membrane that acts as a cavity.

T-Kone Plaster acts from the inside of a house by creating an 8 mm air gap, equal to 5.4 litres/m², between the original wall and the new finish. Thanks to its mesh, this can be coated with a new layer of plaster while its special profile at the base is able to counteract moisture through micro-ventilation.

Rot-proof, non-toxic, resistant to atmospheric agents and fungi, T-Kone Plaster is an effective and permanent solution for restoring walls.

To find out more about our studded membrane, EXPLORE OUR WEBSITE.

Tips for the correct installation of studded membranes

It is essential to avoid making errors when designing and installing membranes for the protection and drainage of foundations: if any damage results over time due to design errors, you will not be entitled to compensation from insurance companies. Moreover, repairing damage to foundations could be very expensive and intrusive, or, in the most extreme cases, impossible to carry out.

THE CONFIGURATION OF THE WATERPROOFING SYSTEM, THE CHOICE OF SUITABLE MATERIALS FOR THE STRUCTURE AND THEIR CORRECT INSTALLATION ARE THE KEY ELEMENTS FOR WORK PROPERLY DONE.

Here are some tips from us for properly done installation:

1- To obtain excellent drainage, use TeMa Building membranes bonded with non-woven fabrics that act as filters to prevent soil from clogging the system.

2- To provide mechanical protection for the waterproofing, use studded membranes, following the specific instructions for installation. The TeMa Building range offers membranes with specific mechanical resistance and various dimensions of studs, making them suitable for the different types of performance required.

Important: As they have concentrated pressure points, membranes with particularly sharp studs may easily mark the waterproofing membrane if installed with the studs facing it.

The studs of TeMa Building membranes have a truncated cone shape and the larger surface area in contact with the waterproofing allows safe installation with the studs facing both the membrane and the ground.

3- The mechanical fixing systems of the TeMa Building range are specifically designed for easy and safe installation of the membranes. They can also withstand stress resulting from backfilling and the natural settling and subsidence of the soil, without damaging or tearing the membrane.

Important: The application of the flame-applied membrane alone is not recommended, since it makes the system more vulnerable during backfilling operations and settling.

Thanks to these precautions during installation, you will be guaranteed an excellent and long-lasting result, protecting the building from seepage and damp!

Visit our website to find out about all our membranes!

TeMa waterproofing systems

Three-layer waterproofing membrane for sub-tile applications for the protection of walls and floors from steam transmission with accessories

Discover the theme solutions to make your bathroom safe and dry, watch the video