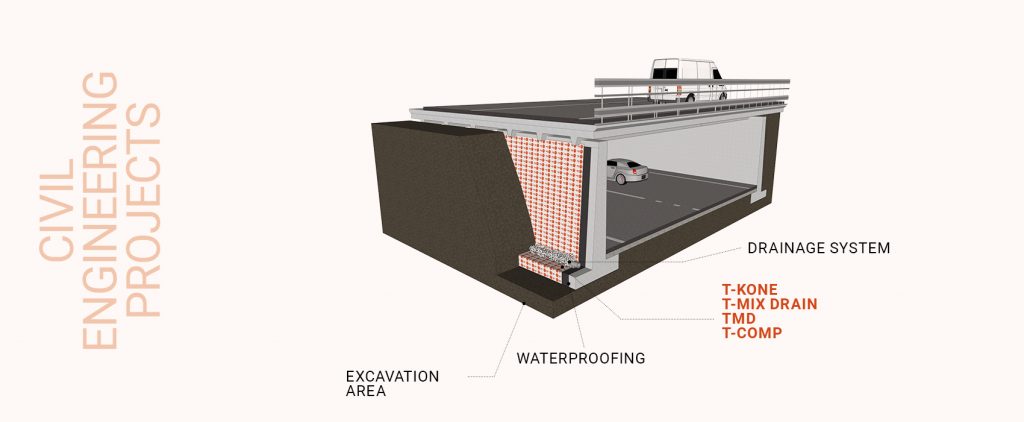

Retaining walls: applications in residential, commercial and infrastructural contexts

Supporting walls or retaining walls are vertical structures intended to support and retain accumulations of natural or artificial materials and ensure their stability.

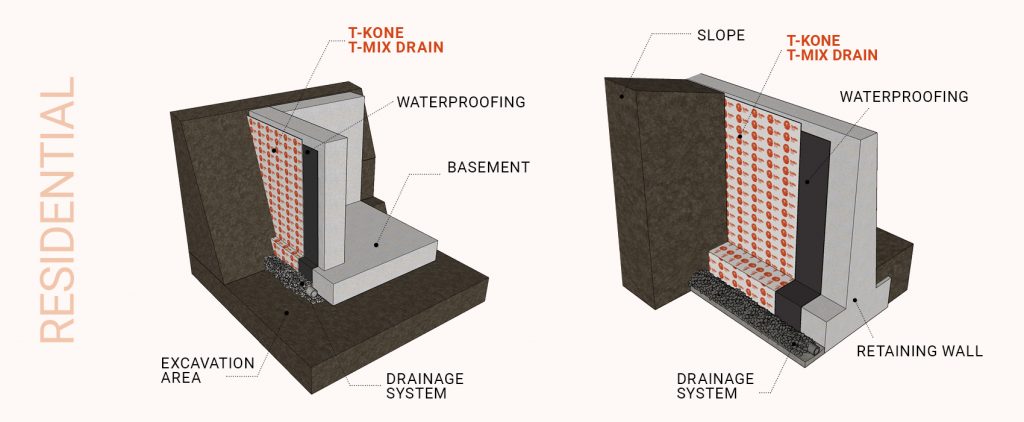

In the part in contact with the ground, the supporting structures are naturally covered with a waterproofing membrane, which must be protected from damage during construction operations and during subsequent settlement of the ground. The mechanical protection of the waterproofing is provided by TeMa Building Solutions T-Kone studded membranes, which also act as damp proofing, slowing down the absorption of moisture.

Moreover, when placed with the studs facing inwards, these membranes create a micro-ventilation space that is beneficial in keeping the structure dry.

In some cases, a rainwater collection system is planned around the perimeter of the building. It is necessary to use drainage geocomposites bonded with a geotextile such as T-Mix Drain, which conveys water to the drainage system envisaged in the project.

Supporting walls are used in a wide variety of areas in the building industry, from residential to infrastructural and commercial contexts.

Let’s take a look at the application in specific fields.

Residential context

It is essential to protect the underground rooms of homes, whether they are used as garages, cellars or basement rooms, in order to prevent the moisture seepage, which would damage the structure and make the indoor environment unhealthy.

TeMa Building Solutions products meet this need and are efficient in this respect.

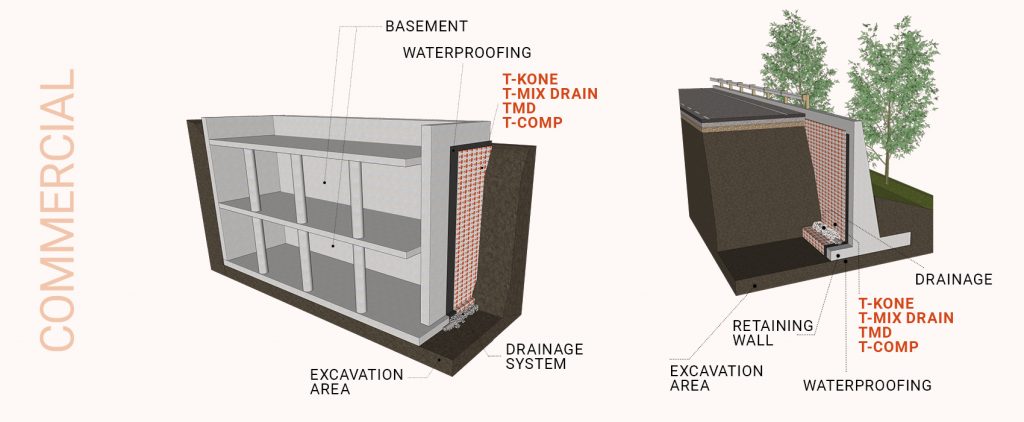

Commercial context

TeMa Building Solutions products are also ideal for heavy loads such as underground car parks or warehouses in commercial buildings.

In such environments, TMD, the studded membrane bonded with LDPE backing foil for the mechanical protection of waterproofing membranes and the T-Mix Draindrainage geocomposite for the drainage function can also be used. In addition, the T-Comp fibreglass mat performs the subdivision function.

Infrastructures

In major infrastructural works, membranes and geocomposites must be able to withstand and resist heavy loads from the ground and hydrostatic thrust. The effectiveness of TeMa Building products is also proven for this type of construction work.

To learn more about the mentioned products, click here.

- Published in BUILDING, Drainage geocomposites, Foundation and underground structures - Damp proofing systems, news, Retaining walls elements

Protecting the vineyard landscape: tried-and-tested technologies… sitting lightly in the field.

The photo conjures up a lofty tale: “Autumn arrives and with it, the first rains, days draw in, the temperature starts to drop and, above all… it’s harvest time!”

We’re in the eastern corner of the Veneto region, the Prosecco hills have outdone themselves once again this year and a steady stream of grape-laden trailers continue to roll past on their way to the wineries. But this year’s harvest has had to contend with rather uncertain weather patterns: frosts in late spring, persistent rain interspersed with dry spells, with violent storms and hail over summer.

These conditions certainly don’t help the soil, putting it at risk of slips, subsidence and erosion. But if we apply TeMa Geo Solutions’ modern technologies and materials designed for this very purpose, we can protect the land from damage and, what’s more, do it in a sustainable way.

Not far from here, just a few kilometres from our headquarters, the Prosecco hills fall largely within the UNESCO World Heritage Site, meaning any measures must be strictly reconstructive, designed to protect the status quo and absolutely non-invasive: “gentle” on the environment.

TeMa Geo Solutions has come up with high-performance solutions to control the natural erosion of the soil, reinforce slopes, and drain water with:

- biodegradable fibre matting made from 100% natural jute such as Ecovernet® J500 XL and Ecovermat P Grass, which provide protection to stop soil being blown or washed away by the elements, and encourage vegetation;

- the K-Mat F erosion control synthetic geomat;

- reinforcement geogrids such as X-Grid PET PVC, which can withstand considerable stress levels;

- the Speedrain drainage geocomposite, which drains away water from the surrounding soil, stabilizing any surface slips.

Products

If you wish to receive more information, CONTACT US or take a look and download our “Vineyards” catalogue.

TeMa Technologies and Materials’ sustainable choice

We started out almost 30 years ago and being environmentally responsible has always been part of our philosophy, partly due to the fact that our headquarters are located less than three kilometres from the core zone of the hills recognized as a UNESCO World Heritage Site, and just over 6 km from the edge of the Cansiglio forest.

So protecting the environment was always going to be one of our key commitments, not just in our manufacturing systems, but also in the innovations implemented in the solutions we offer our customers.

Reinforced soil and CO2 savings

Our engineers have redesigned the reinforced soil system, leveraging the very pressure of the soil retained by geogrids, so as to save millions of cubic metres of concrete and aggregate, which would otherwise have to be carried to the site in hundreds of truckloads. Now it takes just one: a considerable saving in terms of CO2 in line with the goal of reducing the carbon footprint, which is the total amount of greenhouse gas emissions generated by a product or a process.

Our geonets and geogrids are made partly from recycled plastic sourced from facilities that are controlled to ensure the resulting plastic meets our standards. A substantial difference in terms of both the collection of material to be recycled and conditioned, and the recycling procedure itself (the material in question is high-density polyethylene, and polypropylene, which comes from bottles, containers, capsules and so on), as well as its preparation, for which – in order to ensure quality – we have set up two plants: EcoTeMa in Russia and Replastica in Romania.

A sustainability journey that TeMa has embarked on and is committed to pursuing further, continuing to invest in technologies and systems with a view to achieving zero emissions by 2050.

Our recycling production process

Material sorting: only materials that meet preset standards in terms of quality and type make it to the next stage. The sorted material is first shredded and then washed, then shredded and washed again. Only then does it qualify as a “raw material” ready to be turned into granules and then extruded and used in TeMa production processes.

It is supplied to our facilities across the Group for them to make into products to be introduced into the market in line with the specifications laid out by designers and in compliance with the legal requirements in the individual countries.

Where does the washing water end up?

The water used for washing is also reused once suitably treated. The portion of water not used is disposed of in compliance with specific government standards on environmental impact.

Renewable energy

Along with plastic recycling and a focus on reducing the amount of carbon dioxide released into the atmosphere, the IWIS Group has installed 3 photovoltaic systems of its own – with rated outputs of 200 kWp, 150 kWp and 100 kWp – as well as a cogenerator, together producing 50% of the energy used in manufacturing.

If you wish to receive information about it, CONTACT US.

- Published in CORPORATION, Research and development, TeMa Technologies and Materials

Damp Proofing vs Waterproofing

Damp-proofing and waterproofing are terms we often encounter in the building industry and they refer to a specific function. In product presentation and technical documentation, the two terms are often equated, leading to confusion, also due to “cross-translations” from English into other languages.

Important differences distinguish these two terms. Whether you are planning a new construction or a renovation, it is better to know the meanings in order to ensure optimal construction that also allows, when envisaged, comfortable living on basement floors.

In this article, we can try to better understand the difference between the two terms.

What does “damp-proofing” mean?

Damp-proofing is the function of a material that can slow down or prevent, on a surface, the absorption of moisture (i.e. in the absence of hydrostatic pressure). The main purpose is therefore to slow down moisture seepage, but it does not prevent the flow of water to the interior.

These materials also often have the additional important function of creating a barrier between the ground and the surfaces to protect the waterproofing layer, increasing its safety and durability over the years.

What does “waterproofing” mean?

Waterproofing means the ability of the system to be totally resistant to water in the ground, which exerts hydrostatic pressure. Such as groundwater, for example.

TeMa Building Solutions always guarantees a range of products and has all the solutions you need.

For the damp-proofing function we have T-Kone, the HDPE studded membrane for foundations and underground structures, and its accessories including washers and nails for installation (T-Plug + Nails), whereas for the waterproofing function we have T-Bentostop F and T-Bentostop F XL: waterproofing bentonite geocomposites that self-attach to concrete for foundations in that material.

Contact us for further information or visit our product pages specifically for damp-proofing and waterproofing functions.

The importance of guaranteeing protected foundations

Cloudbursts are sudden heavy rainstorms that, unfortunately, are becoming increasingly frequent. Short but intense, they mainly occur in the summer season, even if it is a myth to debunk because they are also a common occurrence in other seasons. The enormous amount of water concentrated over a short period of time, makes these phenomena potentially dangerous and a possible threat to the foundations of buildings.

How to Protect Foundations

This is why designers are increasingly focusing on the best protection for buildings and properties in contact with the ground. The sudden changes in the amount of water run-off and the gradual increase in the groundwater level make earth-retaining works fragile when these factors have not been considered.

TeMa Building Solutions

Adequate systemic design is essential in the case of hydrostatic thrust, just as it becomes fundamental to monitor various factors, including: descending water resulting from precipitation, water and/or damp rising due to capillary upward flow, groundwater and condensation which, due to the difference in temperature between the ground and interior spaces, forms on the walls of rooms close to the ground. It’s also important to bear in mind the likelihood that several phenomena may exist at the same time. TeMa Building Solutions is our division highly specialised in protection and waterproofing systems. Our research team has developed products ideal for counteracting the hazards caused by these seasonal weather events. It provides solutions for the protection of foundations and water drainage to reduce the volume of water close to underground structures, both vertical and horizontal, in contact with the ground and where groundwater or dispersed water is present.

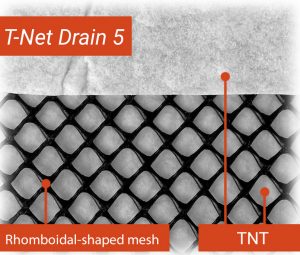

TeMa Geocomposites

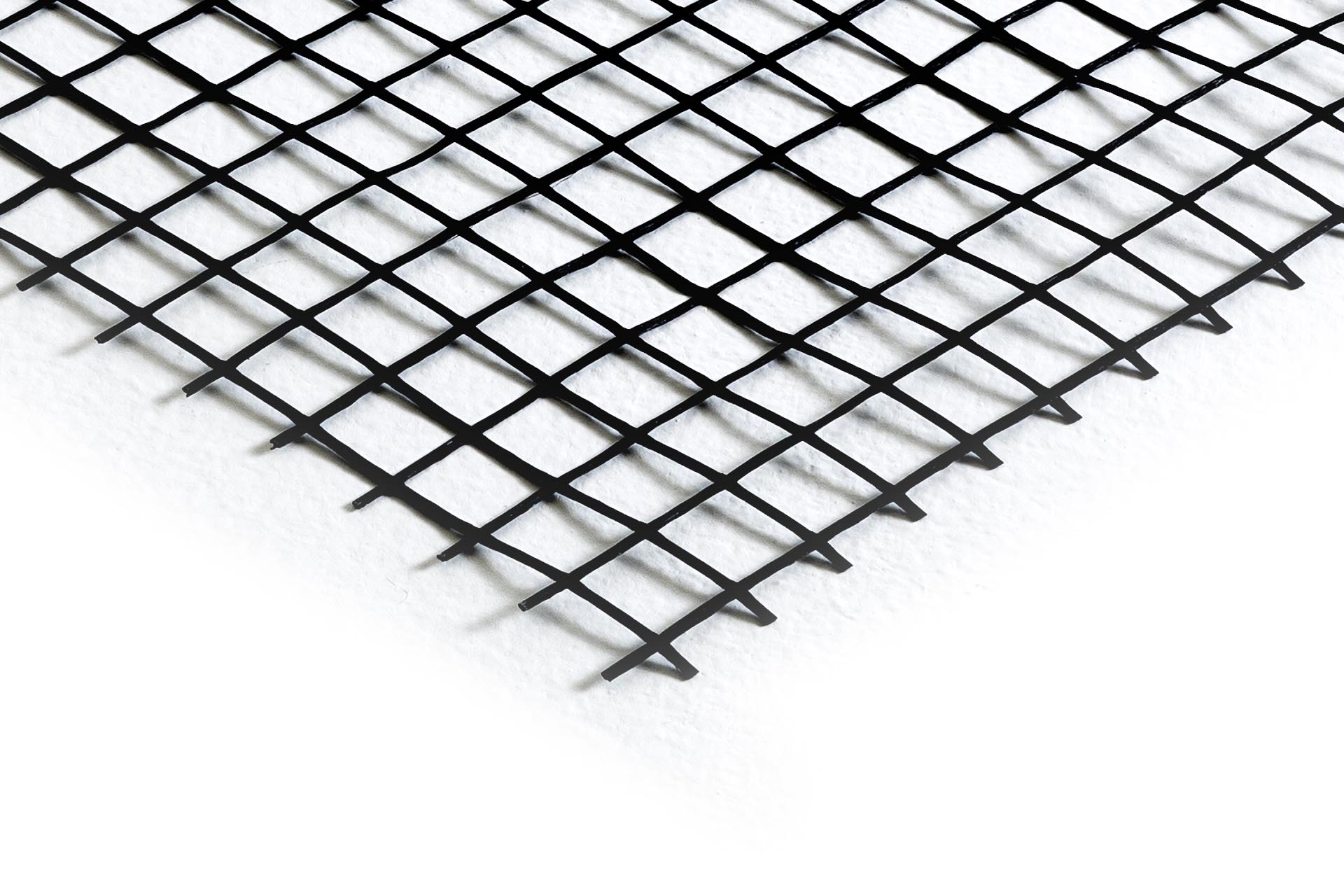

Our geocomposites have been designed to perform the dual function of filtering and draining water, dispersing energy from the hydrostatic load. They include T-Net Drain 5, which channels the flow of water to the water collection system around a building thanks to the rhomboidal-shaped mesh geo-grid coupled with two non-woven geotextiles.

According to recent research in the building market in Italy, damage due to water seepage and damp in earth-retaining structures is the cause of more than 50% of disputes in the building sector. Our designers are well aware of this problem and therefore rely on TeMa, thus preventing such complications.

To learn more and discover the entire range of geocomposites designed by TeMa, go to our website.

The new TeMa catalogues for environmental intervention works

TeMa Geo Solutions has presented two important publications summarising the products and technologies used in the field of major environmental works, which have enabled the Vittorio Veneto-based company to convince designers on all continents.

In addition to novelties, in the new catalogue we present solutions for intervention works in the environmental field that respect a new awareness towards protecting our natural heritage, which includes much hilly terrain and cultivated slopes. In recent years, these have been increasingly affected by climate changes that, in turn, have intensified some weather conditions.

We have included TeMa products for the major environmental works sector in the new Geosynthetic Products catalogue by TeMa Geo Solutions. In 48 pages, we present 29 products separated according to categories: drainage geocomposites, studded membranes, geonets, geogrids, geomats, biomats and geocomposites. They are all the result of research into new materials aimed at solving critical issues related to drainage, erosion control, filtration, separation, reinforcement, waterproofing and protection using dozens of applications (geotechnical and environmental) that the soil requires in certain hydrogeological and morphological situations.

Vineyards Catalogue

The same effective solutions with low environmental impact are offered in the Vineyards catalogue, specifically dedicated to safeguarding the vineyard heritage. It is, indeed, a centuries-old culture that has been a typical part of our lives for generations. We have only to consider the steps built by hand by farmers in the past. In the catalogue, we present various sustainable solutions, specifically for setting up vineyards and for their maintenance. The technological content of TeMa solutions goes hand-in-hand with its spirit of eco-compatibility, which has led to considerable savings, over the years, in terms of raw materials and CO₂ emissions into the air. TeMa has eliminated the use of millions of cubic metres of cement and inert materials with its “reinforced earth” technique, thus avoiding spreading thousands of tonnes of carbon dioxide and particulates that heavy vehicles would emit into the atmosphere in order to transport them.

The environmental choice of TeMa Geo

All this is accompanied by researching equally eco-compatible products that can be used in a natural context without spoiling it or changing its appearance. These are often 100% natural solutions which, despite being degradable over time, achieve their objective of settling the soil in a more than natural way.

Relying on TeMa Geo means making an environmental choice: you will discover that we have built four post-consumer plastic recycling plants to obtain, according to our own specifications, quality recycled raw materials to be used in specific percentages in our products.

To download the new catalogues and get an idea of our work philosophy, go to our Geosynthetics Catalogue and go to our Vineyards catalogue.

- Published in GEO

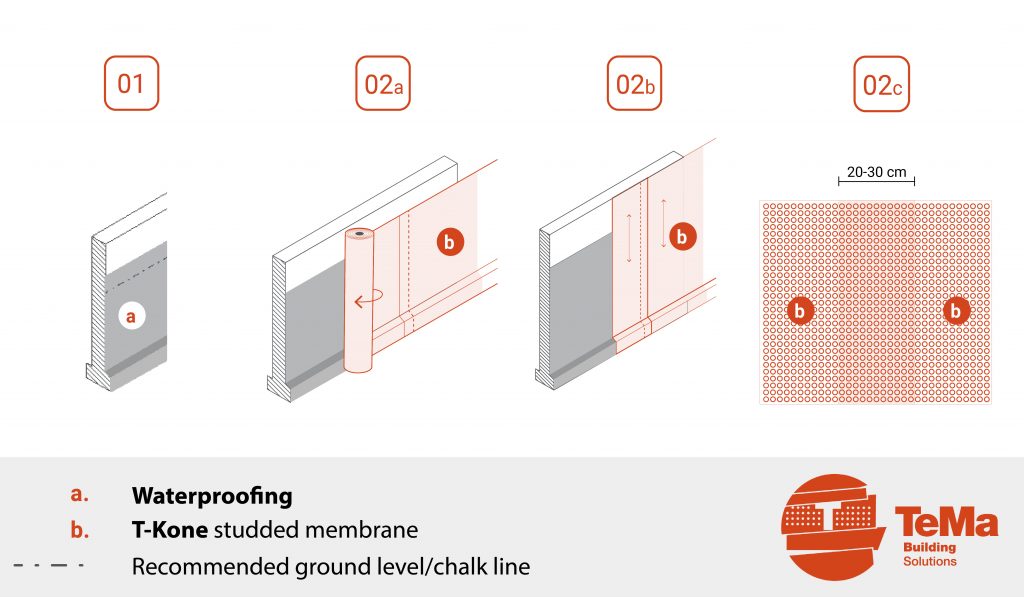

Tips For Laying T-Kone

T-Kone is an HDPE studded membrane available in various versions: T-Kone S, T-Kone, T-Kone G Drain, T-Kone G Drain Plus and T-Kone G Drain Grip. T-Kone S and T-Kone are bare, whereas T-Kone G Drain is bonded with a geotextile, T-Kone G Drain Plus with a geotextile and a damp-proofing element, and T-Kone G Drain Grip with two geotextiles.

As you can see, you will need to make the right choice depending on what you want to obtain. Each solution meets different needs, including the mechanical protection of waterproofing and a drainage function. In any case, these applications are quick and easy to lay. Here, we can discover tips for laying T-Kone.

Mechanical protection of waterproofing with T-Kone

Where do I start?

First of all, you need to clean the work surface of any debris and check the wall to which the product is to be applied so that there are no defects that might damage the materials.

Then you need to use chalk to mark out the area where the drainage system is to be installed (a), making sure that you lay the membrane well beyond this point.

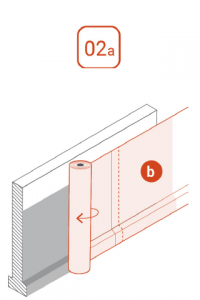

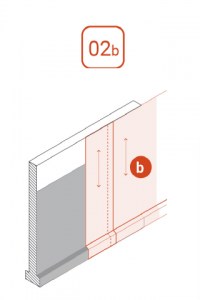

Start unrolling T-Kone (b) preferably from the centre of the wall, with the tab facing upwards, and aligned with the chalk line. The membrane needs to be laid with the studs facing the wall. This will create an 8 mm air gap between the waterproofing and the membrane.

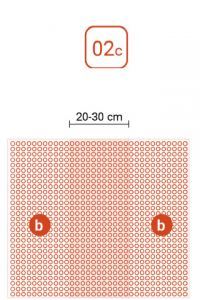

Unroll the panels and apply them horizontally or vertically, fixing them against the wall. If the height of the wall does not allow it, they can be laid vertically and any excess fabric can be cut off. The sections must be placed side by side and overlap by about 20-30 cm on each side (a+b).

These are just a few basic tips for laying T-Kone. Discover all the applications for TeMa studded membranes directly on the site TeMa.

- Published in BUILDING, Studded membranes and accessories

Environmental intervention works in keeping with our philosophy

An environmental reappraisal

Over the centuries the relationship between man and the environment has undergone considerable tensions. Rural development and the impetus in building have undoubtedly disrupted certain landscapes, reducing natural spaces to accommodate new urban and agricultural areas. This type of intervention work has led to a crisis in the ecosystem, imposing re-evaluation of the fragile balance between the economy and the environment.

This is the socio-cultural background that has led to global re-assessment aimed at defining programmes and new territorial management formulas. It has been the driving force behind TeMa Geo Solutions, the TeMa business unit dedicated to environmental intervention works. These are aimed at protecting land and offering the opportunity to operate using eco-compatible solutions and products that integrate into the environment without compromising its appearance or safety.

Sustainable development according to TeMa

Nestled at the foot of the hills declared a UNESCO World Heritage Site, the TeMa headquarters could not help but consistently correspond to this desire for sustainability, widespread in this area for some years now. But how has it contributed? By using raw materials responsibly, with 100% natural solutions and intervention procedures with low environmental impact.

Natural products

As a concrete example, TeMa addresses the problem of surface erosion of the soil by meteoric rain with Ecovernet® in natural fibres such as jute or Ecovermat® in natural fibres such as straw and coconut – or in biodegradable cellulose fibre. Installing products in this range allows intervention works to be carried out immediately, even in situations with difficult access for on-site vehicles. For such types of intervention works, total integration with the soil is achieved, guaranteeing lasting results over time.

Green intervention works

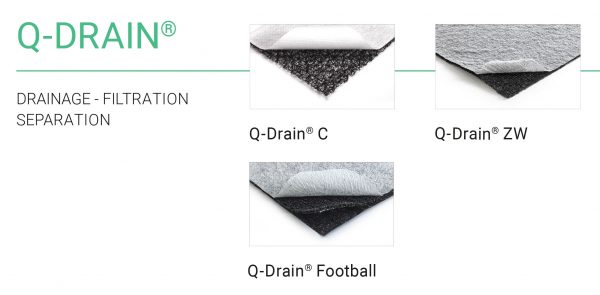

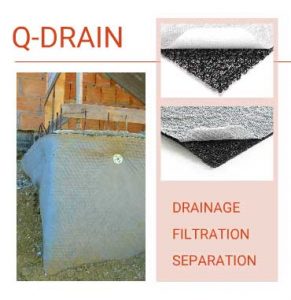

An interesting new development introduced by our technicians is the use of lightweight materials that feature reduced encumbrance, which not only affects the cost of the work but also speeds up the time required on-site. When building drainage systems, for example, TeMa does not rely on that range of inert materials from quarries that need to be extracted and transported. The company uses drainage geocomposites instead, such as Q-Drain, thus avoiding any waste of energy and CO₂ emissions into the air, thus ensuring quick installation.

These are just a few examples to show the potential that the field of environmental engineering has to offer:

- Reduction in costs while maintaining the effectiveness of intervention works

- Sustainability of the actions taken

- Protection and safeguarding of the soil

- Promotion of natural raw materials

To fully understand our philosophy, browse through the new catalogue dedicated to the protection of vineyards, which are the natural and cultural heritage of our lands and an identifying feature of our history. Inside it, you will find products and solutions for responsible and eco-compatible actions.

- Published in Drainage geocomposites and membranes, Erosion mats, GEO, Research and development

The importance of studded membranes

Research conducted in the building market has found that most construction disputes are due to damage caused by water and damp seeping into retaining structures.

Protecting foundations

In order to avoid inconveniences of this magnitude that are discovered in the course of time, designers and installers undertake to protect foundations. TeMa has therefore developed products and systems that protect waterproofing during backfilling operations, thus guaranteeing the stability of intervention work over time. For practical purposes, we propose two types of fairly common intervention works in civil engineering by showing you how two of our studded membranes work.

Retaining walls

Retaining walls are intervention works that have the main purpose of retaining slopes or soil embankments during works such as the construction of roads below ground level. Various types of wall can be built: in masonry or reinforced concrete, or using precast concrete elements.

Whichever solution is used, you always need to consider and comply with specific hydrogeological features: TeMa laboratories offer a range of membranes that meet such requirements, whereas technicians and installers can assist in choosing the best solution to use.

Mechanical protection of waterproofing

For the mechanical protection of waterproofing you can choose T-Kone, which also performs a damp-proofing and drainage function. Damp proofing creates a physical barrier between the structure and damp soil and avoids any possible damage to the waterproofing membrane, both during onsite operations and soil settlement.

The T-Kone family is part of a range of bare HDPE studded membranes (such as T-Kone S). Alternatively, these membranes can be bonded with a geotextile such as T-Kone G Drain or with a geotextile and a damp-proofing element such as T-Kone G Drain Plus.

Diaphragms and berlin walls

Suppose we need to work in an urban context doing underground intervention work. First of all, we must guarantee the stability of the structures surrounding the area to be excavated.

Diaphragms and berlin walls are used in situations where it is impossible to create excavation walls with an appropriate slope to prevent landslides or structural subsidence. In the form of steel/ reinforced concrete piles or walls, they are driven deep into the ground and coupled with TeMa membranes, which provide damp-proofing, mechanical protection or drainage functions.

Damp-proofing, mechanical protection or drainage functions

For this purpose, products such as Q-Drain can be used, which have a polypropylene monofilament drainage core bonded with one or two non-woven geotextiles, also made of polypropylene. These filter water and adapt to the conformation of the ground, thus guaranteeing stability.

These are just some of the membranes we are able to supply. Find out which one is best for you and assess the best solution with our team of experts. TeMa will assist you throughout each phase of the design process.

To discover TeMa products, visit the website.

- Published in BUILDING, Foundation and underground structures - Damp proofing systems, Foundation and underground structures - Drainage systems, Foundation and underground structures - Systems for mechanical protection, Foundation and underground structures - Systems for Waterproofing, Retaining walls, Retaining walls elements, Studded membranes and accessories

Geosynthetics: Advantages and Applications

Our passion for work does not stop, it simply continues at our company, in a little more limited way. You certainly cannot see us running up and down building sites or going in and out of our research labs, but we can assure you that we are still working on our production of geosynthetic products with the same commitment and perseverance in order to formulate new projects and develop ideas that we will see materialised soon, once everything has ended.

TeMa and Geosynthetic Products

TeMa Geo is the TeMa division created almost thirty years ago with the aim of exploring and expanding the world of geosynthetics, which it still does today. By “geosynthetic products” we generally mean all categories of synthetic coverings that are not only used in contact with earth or other building materials but are also appreciated for their use in various building fields. In the building industry, their main advantage is that they are user-friendly in technical terms, which is why engineers and planners prefer them to other technical solutions.

The Advantages of Geosynthetics

The advantages of geosynthetic options not only lies in the fact that they are easy to use but also in their cost-effectiveness: certainly less expensive, they provide excellent performance that remains unchanged over time. Furthermore, their versatile use makes them the ideal solution to various on-site problems.

Geosynthetic Products “In the Field”: the Serravalle Project

In more practical terms, today we want to tell you about the intervention works we carried out in the Piedmont region in 2016. It involved extension works for Serravalle Retail Park. In preparation for the works, we had to make the slope in front of the new complex safe. In order to proceed, we had to prepare several reinforced soil structures, separating them into banks, and solve the problems of surface drainage for the management of water, whose catchment area was located above the area.

For works of such magnitude, we used geogrids from the XGrid PET-PVC range as a structural element. In addition, to avoid any seepage in the future, drainage elements were installed close to the reinforced structures of the horizontal sections of each berm. This is just one of our products and one of the many fields of application explored by TeMa.

To discover all our membranes, visit our section dedicated to products.

- Published in GEO, Geogrids, Reinforced earth structures, Reinforced earth structures - Drainage