Join us at Ecomondo 2023

Climate change and extreme natural events are having an impact on the planet’s life balance. The current international focus on the ecological transition and the circular and green economy is making it more and more imperative to make innovative decisions on this front. This is why our TeMa team of engineers and technicians will be attending Ecomondo 2023 to share with professionals, industry, stakeholders, policy makers, opinion leaders and local authorities just how significant a role our products can play in this green drive.

Ecomondo will be held from 7 to 10 November 2023 at Rimini’s exhibition centre. This is the leading international event on the European calendar for sharing and comparing strategies that will shape the EU’s environmental policy. Which is why it’s important to take part.

There’s a well thought out programme packed with conferences, seminars and workshops. Over the four-day show, the programme will tackle interconnected macro issues:

- Bioenergy.

- Circular and regenerative economy.

- Site and land maintenance.

- Waste as a resource.

- The water cycle.

- Environmental control and monitoring.

TeMa champions renewable energy, recycling and sustainable geotechnical projects.

Over our 30 years in the business, and with ever-growing awareness, TeMa has ventured into the realm of sustainability, presenting environmentally friendly solutions for geotechnical projects.

Since our inception, we’ve specialized in reinforced soil solutions for road embankments or ditches, slopes and hillside terracing, landfills and contaminated sites.

No matter what the situation, even in an urban context, there are always green solutions to take the place of concrete. Our catalogue features products that are as high performance as they are sustainable, like biodegradable matting (including pre-seeded mats), geonets and geomembranes. When it comes to handling, there are considerable CO2 savings: there’s no need for gravel, and the soil required is found on site, so no added carbon footprint.

What’s more, our geogrids have earned their reputation as a key substrate in road construction, built to provide lasting strength and withstand cracks or minor subsidence, resulting in a smoother ride and safer road surface.

Join us! We look forward to showing you some of our past projects from around the globe, and some cost-effective and intriguing solutions, such as a horse racing track produced in South Africa built to cope with pounding hooves, even after rain.

We’ll be attending Ecomondo to showcase our solutions, as well as our business decisions:

Part of our products are made using pre-used plastics we “recycle” in our own plants.

We’ve set up two collection and recycling plants (in Russia and Romania) to handle high-density polyethylene, and polypropylene: we sort the waste material, carry out two grinding and washing cycles, and finish with extrusion and filtration.

…we reuse washing water.

wastewater from the washing process is treated and reused for subsequent processes.

…we invest in renewable energy.

Almost 50% of the energy used in our production processes comes from renewable sources: three photovoltaic systems — with rated outputs of 200 kWp, 150 kWp and 100 kWp — and a cogenerator producing another 800 kWp.

Go here for more details.

Join us at the show!

You can find us from 7 to 10 November 2023 on Stand 506, Hall D1, at Rimini’s exhibition centre.

In the meantime, you can find out more about Ecomondo by checking out the official site: click here.

- Published in CORPORATION, Exhibitions and events, news, TeMa Technologies and Materials

Use of drainage geocomposites in building

Serving multiple functions, drainage geocomposites are a perfect match for geotechnical applications, while they have a number of distinctive properties making them a popular choice in the building industry, too. TeMa drainage geocomposites are light, easy to handle both by carriers and on site, quick to apply… But let’s take a look at the full picture in detail.

What are drainage geocomposites and what different types are there?

Drainage geocomposites are, by definition, permeable geosynthetics comprising at least two elements (one synthetic element and one or more nonwovens).

TeMa offers three main types of drainage products, which all come with the benefit of its considerable experience:

- Geonets, made up of a synthetic HDPE mesh comprising two criss-crossed strands sandwiched between two PP nonwovens to which the mesh is thermally bonded, like T-Drain.

- Geomembranes like T-Kone and TMD, HDPE studded membranes with different stud heights (8, 10, 20 mm) laminated with a nonwoven.

- Monofilaments, made up of an extruded synthetic monofilament core sandwiched between two nonwovens to which the core is thermally bonded, such as T-Mix Drain.

What are their possible applications?

The drainage geocomposites from TeMa Building Solutions cover numerous applications: pitched roofs and ballasted flat roofs, flat green roofs and trafficable flat roofs, standing seam metal roofs and walls, foundations and underground structures, and damp-prone internal walls.

These are all applications that require special attention to drainage as they are exposed to different weather conditions and, in some cases, to groundwater as well: the risk of ponding increases, encouraging damp and, if the waterproofing layer becomes damaged or has too much pressure on it, water seepage and leaking can become an issue.

What purposes do drainage geocomposites serve?

Their main purpose is draining rainwater and groundwater. This is achieved by the action of separation, made possible by the nonwoven, which acts as a filter: the particles that manage to get through it are so extremely small as to have no effect on the proper functioning of the drainage system.

The studded membrane geocomposites also serve the important purpose of providing mechanical protection for waterproofing, which is valuable in roofs and simply essential in underground structures if they are to cope with backfilling and settling of the backfill without being damaged.

Which drainage geocomposite should you choose?

To choose the right product, you need to look at what performance is required. Designers know this well: it depends on the amount and “quality” of water to be drained, and hence on the morphology of the site, whether there are active aquifers, and so on. Loading is another factor to be taken into consideration, in such applications as green roofs, as well as for trafficable roofs and walkable surfaces.

- Published in BUILDING, Drainage geocomposites

Sustainable finance: sustainable development

It’s interesting to realize just how much the environmental culture of a business can be a way to accelerate its development, even by allowing it to access finance that’s vital for its growth and innovation: this is where the concept of sustainable finance comes in.

No self-respecting company report is complete without covering sustainability, the circular economy, wellbeing and the environment, which have different connotations for different businesses and are promoted to varying extents over the course of their lives.

The fact that this has become a “mature” issue can be seen in the need and, indeed, the will of companies to meet the requirements of ESG “certification” (Environmental, Social and Governance), since those companies who are attuned to these worlds are destined to have a more productive future and be more attractive to financial backers.

So, by sustainable finance we mean finance that supports the capital and investments of businesses with future-proof projects, especially from an environmental point of view. This is a practice aimed at investing to develop production processes, in addition to funding research into raw materials and end-of-life disposal of products, with the upstream decision process generally focusing on protecting the planet.

The cornerstones of sustainable finance

There are three factors taken into consideration, into which the tangible application of sustainable development can be narrowed down.

- Environmental factors: these include issues like the need to promote greener, more energy-efficient production processes. They very much hinge on the themes of circular economy and zero-emission activities, as well as on preventing pollution and protecting biodiversity.

- Social factors: these focus more on reducing inequality and on developing an inclusive system, one that is pro-human rights, in addition to investing in training and in the wellbeing of communities.

- Governance factors: these ensure that both environmental and social factors are included in the company‘s decision-making processes.

TeMa and sustainability

TeMa Technologies and Materials has long been a believer in using sustainable materials and creating sustainable solutions, even in the building and geotechnical fields.

Reinforced soil projects, on both a small and large scale, are a case in point: the technique of using soil as a retaining material, instead of concrete, certainly makes the structure more environmentally friendly, providing benefits in terms of both the landscape and liveability (they often double as noise barriers, click here for more information).

We provide 30-plus years of experience in the development of geogrids and geomembranes supplied in rolls, which are easy to carry to even the most inaccessible sites, and are ideally suited to the construction of landfills, tunnels, roads, reinforced soil projects and drainage ditches.

In addition to the many advantages in terms of construction, they come with the no small benefit of energy savings and the reduction in air pollution achieved when using geomembranes instead of traditional gravel: in terms of transport alone, the number of trips (trucks) drops from 100 to 1.

Out of our many past projects, one standout would have to be the track of a race course in Johannesburg, in South Africa.

In addition, TeMa supplies sustainable products like natural fibre matting — made from materials such as jute, straw, coconut and cellulose — that are particularly well suited to surface erosion control on grass slopes.

- Published in CORPORATION, Research and development, TeMa Technologies and Materials

TeMa at the 12th International Conference on Geosynthetics.

We too will be at the 12th edition of the International Conference on Geosynthetics that will take place in Rome, at the Parco della Musica auditorium from 17 to 21 September 2023, and which will involve a full programme of meetings between professionals (further information about the events here).

Four days of training and information meetings on geosynthetics, exploring all sub-types: woven and non-woven geotextiles, geogrids, geonets, geomats, drainage and reinforcement geocomposites, and geomembranes.

Geosynthetics are becoming increasingly popular in applications and fulfil various functions (often combined). For example:

- Drainage – drainage geocomposites and geonets.

- Filtration and Separation – woven geotextiles and non-woven geotextiles.

- Reinforcement – woven geotextiles and geogrids.

- Protection of waterproofing – studded membranes with truncated conical or star-shaped studs.

- Erosion control – geonets, geomats, biotextiles.

- Mechanical protection – non-woven geotextiles, composite geotextiles.

- Special applications – various geosynthetics made to specific requirements.

The main topics discussed will cover various fields of application, including anti-seismic design to road and railway embankments, erosion control, filtration and drainage functions, as well as an analysis of case studies.

The world of research is continuously evolving and the scheduled meetings will provide an excellent opportunity for sharing experiences and recent technical developments with engineers, geologists, consultants, contractors and whoever is involved in research and using geosynthetics.

During the exhibition event visitors will be able to take part in technical conferences, the Giroud lecture, special lectures and short courses , as well as visit the exhibition hall to meet manufacturers.

TeMa has thirty years of experience in using geosynthetics

The international event, entitled ‘Leading the way to a resilient planet’, fully represents the reason why TeMa began to manufacture and experiment with geosynthetics from the mid-1990s onwards: to research the most suitable technologies and materials for use in the construction of buildings and geotechnical works.

We have been involved in continuous interaction, also due to an increased awareness of major environmental issues. This has enabled us to broaden our range of products and expand in 80 countries worldwide.

Today, our catalogue includes many products that meet specific requirements for landfills, tunnels, road embankments, river banks and reinforced earth structures, gradually increasing performance for surface erosion control, rainwater drainage, and the reinforcement of grassy slopes.

The geosynthetics sector is rapidly developing and we are making huge investments, especially in research, so as to supply our customers with the best solutions, also tailor-made, for their projects. We share the same ‘urgency’ as our partners to pursue our unwavering ideal of respecting the environment and the hydrogeological protection of the land.

We look forward to seeing you in Rome from 17 to 21 September 2023, at Stand 22.

Meanwhile, you can discover all the details about the event here.

Reinforced earth retaining walls: specific products for each function

The function of retaining wall structures is to retain and reinforce soil faces. They can be built in a multitude of areas, including private ones such as gardens and vineyards, as well as public areas such as roads, railways and embankments.

They meet the need to recover usable spaces as they can also be built with a steeply sloping face.

The authentic green appearance

Nowadays, the modern building industry is highly aware of sustainability and territorial integration. Under certain conditions, reinforced earth retaining walls can replace conventional concrete walls, without underestimating the aesthetic appearance of the landscape. This is even more important in areas subject to landscape restrictions that require the preservation of natural aspects using specific materials and construction techniques.

TeMa Building solutions integrate these trends by catering to various problems concerning land conformation and hydrogeological protection.

The functions of reinforced earth retaining walls and the products required to achieve them

Slope gradient, exposure to weather conditions (including severe ones) and the mechanical properties of the terrain often require technical solutions that stabilise a slope. Synthetic products can be used, each one performing a specific function.

Reinforcement with geogrids

The compressive strength of the soil is combined with the tensile strength of the geosynthetic product (such as T-Grid). The friction involved develops a tensional state that stabilises the structure.

Profiling with formwork units

Electro-welded metal structures such as formwork units provide a shaping of the soil face up to a 65° slope.

Controlling surface erosion with erosion control mats

Severe or prolonged weather conditions, such as strong winds and sudden downpours – and the resulting surface run-off of water – could lead to erosion and depletion at the face of reinforced earth layers, particularly if they are fully greened. The solution to this problem is to use, on the face of each layer, three-dimensional synthetic mats such as T-Mat made of polypropylene or K-Mat FG Green made of fibreglass. Alternatively, natural, biodegradable mats made of jute fibre such as T-Juta 500 can be used (also available in an XLversion).

Soil containment using gabions

An alternative solution to reinforced earth walls can be found in walls built using double-twisted wire mesh gabions, such as T-Gabion, filled with pebbles. Gabions are also an interesting solution for smaller residential projects: they provide containment while offering a different and innovative aesthetic appearance.

- Published in BUILDING, Retaining walls, Retaining walls elements

Reinforcement of slopes and embankments

Slopes and embankments can be used as road or railway embankments, raised flood banks and floodplains, and even vineyards, especially in a territory such as Italy, one of the countries with the largest number of UNESCO World Heritage landscapes in the world.Many of those greened terraces are true reinforced earth structures, with their stability guaranteed by a well-tested construction technique.

Stability for slopes and embankments

Reinforced earth structures are retaining works that allow slopes and embankments to be supported, including steep slopes. They do not involve the use of concrete constructions, which would be more detrimental to the landscape.

The soil has a natural capacity for compressive strength. When combined with geosynthetic grids (which have excellent tensile strength), they create a stable system, as the features of the two components provide a high-performance composite.

The open mesh structure allows reinforcement geogrids to develop passive resistance along the transverse ribs, as well as creep resistance of the geosynthetic grid in relation to the soil. The TeMa Geo Solutions range includes X-Grid geogrids, available in a variety of models depending on the type of project.

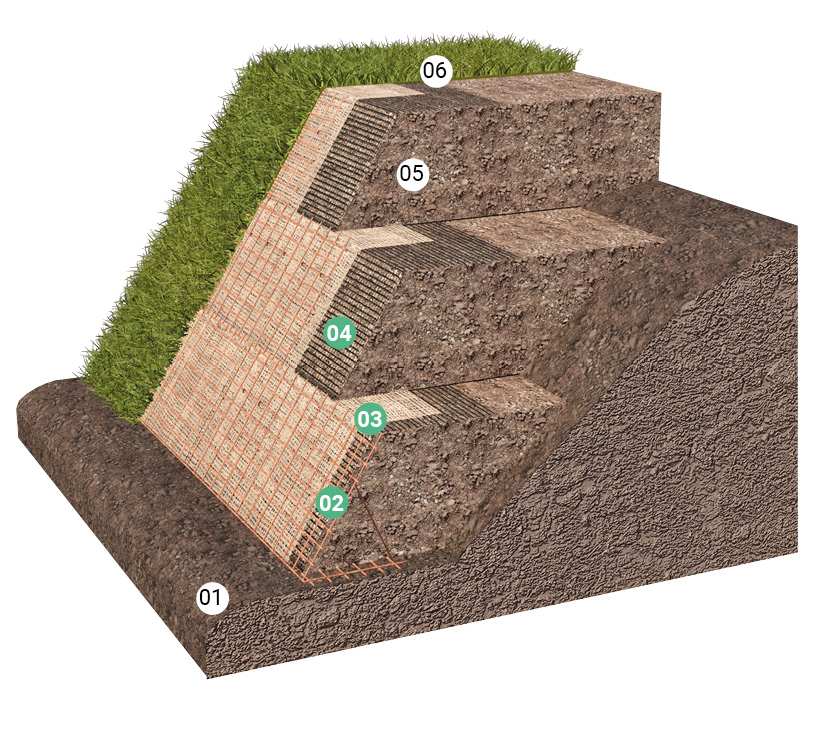

How to position the geogrid in the layering of a terrain?

Each slope needs to be carefully and expertly engineered. However, in addition to the need to reinforce the raised earth structure with geogrids, it is essential to ensure surface erosion control using synthetic or natural erosion control mats and shaping with electro-welded wire mesh formwork.

The X-Grid geogrid must be applied to each ‘block’ of soil supported by the formwork, positioned between the backfill soil and the erosion control mat. An external wrap-around part, measuring no more than 150 cm, must be provided for the formwork system by installing formwork stiffening ribs approximately 30 cm apart.

- Foundation soil

- Metal formwork

- Erosion control mat

- Geogrid

- Backfill soil

- Grassed surface

- Published in environmental, GEO, Geogrids, Reinforced earth structures

Ballasted roofs: why gravel, and how to protect their waterproofing

Something of an innovation in the Italian building scene, while also being a useful device for protecting the roof, the ballasted flat roof is a solution that can become a distinctive feature of either a residential or commercial building.

Unlike the traditional system involving the use of concrete, using gravel is an option that brings a number of attractive advantages:

- it protects the roof against wind and UV rays

- it protects the roof against mechanical damage

- it is low maintenance

- it provides thermal comfort in summer as it shades the roof

- it makes the whole roof system practically fireproof

- it is long lasting.

In building, the choice of a ballasted roof is often prompted by aesthetic reasons for a holiday home or a hotel by the sea, or in an area with high sunshine hours… while it also caters to the need for optimal insulation and low maintenance.

The TeMa Building Solutions answer for protecting ballasted roofs

When gravel is laid, the load can tear the waterproofing layer on the roof underneath, and this comes with the risk of leaks, with all the ensuing stain, mould and structural damage issues.

So it is important to address the need for rainwater drainage and mechanical protection of the waterproofing.

TeMa Building Solutions has come up with a product that serves multiple functions: the product in question is T-Kone G Drain, the studded membrane (which serves to protect the waterproofing) featuring a geotextile (addressing the need for filtration and separation).

Placed between the gravel layer and waterproofing, T-Kone G-Drain is thin, strong and ideal for an effective build-up without the bulk.

- Published in Ballasted roofs, BUILDING, Studded membranes and accessories

Lifelong learning

The term lifelong learning refers to the process aimed at ensuring skill levels keep pace with new professional needs and market innovations as they emerge. In the field of residential, commercial and infrastructure construction, technologies and work processes are developing constantly and at a heady pace, driven by research and by the demands of designers.

Over our 30 years in the business, TeMa Technologies and Materials has interfaced with numerous entities, has broadened its product range and, above all, has researched and come up with solutions that cater to the technical, business and logistical requirements of a fast-evolving market. TeMa’s allure lies in our close relationship with designers and operators, being there to provide support and spearheading training and ongoing learning.

So, while competition is strong, here at TeMa we respond to the challenge with professional growth, specialization and refresher training. The new developments and the skills that put us in a position to tackle challenges, site after site, project after project, are all part of our end customer focused approach.

We’re all convinced that sound technical learning can make all the difference when it comes to the success of even the most ambitious projects, which is why we expect our in-house personnel to engage with this learning, and why we also offer training to all the people choosing our solutions each day.

We offer monthly webinars and in-person meetings during which we explore the issues to be dealt with in each specific field, along with legislative aspects and technical aspects, above all leveraging practical examples, because hands-on experience promotes learning.

The meetings, which are almost invariably accredited, last anything from a few hours to a whole day, allowing attendees to explore the subjects in depth, ask questions and seek clarification from our experts.

- Published in CORPORATION, Research and development, TeMa Technologies and Materials

Green surfaces and green roofs: benefits and technical ins and outs

In recent years, “green” has become more and more of a buzzword, encompassing simple and cost-effective solutions that can be adopted by anyone with a roof. We’re talking green roofs, which, in addition to bringing undeniable environmental benefits, are the perfect place for relaxing with the family or enjoying summer drinks with friends. The origins of roof gardens date back to ancient times — think Hanging Gardens of Babylon — and, today, are built for extreme reliability, including long service life, with excellent products producing even more advantages.

Let’s take a look at the full picture in detail.

The advantages of green areas

For the environment

Plants and grass are natural carbon sinks, absorbing CO2 and releasing oxygen, in addition to filtering particulate matter. In addition, they lessen the urban microclimate effect by lowering temperatures by several degrees centigrade, and reduce electrosmog caused by any electronic device.

They muffle noise and, if designed well, absorb and retain the early sudden downpours associated with significant rain events.

A series of sustainable improvements for urban wellbeing, improving air quality with less smog and particulate matter.

For occupant comfort

Vegetation also acts as natural thermal insulation — which is no small advantage given the energy crises of recent months — and soundproofing in loft bedrooms. Furthermore, it provides the roof with effective protection against UV rays, mechanical stress and daily variations in temperature, thus increasing the average service life of waterproofing.

Lastly, creating a garden on a roof increases the value of the property.

From a technical point of view

A green roof build-up comprises a number of layers, including geosynthetics offering better performance than traditional systems in terms of drainage, mechanical protection of waterproofing, and filtration. The products used are lighter and non-bulky, easy to transport and quick to install.

Functions required of the roof

There are 4 main functions involved:

- Reservoir (to hold rainwater for irrigation purposes until it is needed) and drainage (to remove excess water). This combined function is addressed with 20mm HDPE studded membranes T-Kone H XL and T-Kone H XL S.

- Control of surface erosion caused by atmospheric agents. This function is addressed with natural fibre matting T-Juta 500 and the synthetic geomat T-Mat.

- Drainage. This is where T-Mix Drain 20 SS comes in, the cuspated-fibre geomat sandwiched between 2 geotextiles.

- Mechanical protection of waterproofing. The geotextiles from the Tematex NW PET range, in white and black, fit the bill.

- Published in BUILDING, Flat green roofs

Technical considerations in building reinforced soil walls

Reinforced soil walls have proved highly popular in recent years and are produced wherever possible, taking the place of concrete-faced soil retaining wall systems.

Employed in a range of different environments, they bring significant advantages, both financial and environmental. Indeed, unlike concrete-faced soil retaining wall systems, they:

- are sustainable because they give a vegetated finish;

- are a great space-saving solution, with slopes as steep as 80° (compared to the 30-40° of natural soil embankments);

- result in less pollution given the smaller number of trucks required to carry construction materials;

- make use of the excavated earth for backfilling, provided it is compatible with stability standards, meaning no more material needs to be brought in;

- blend seamlessly with their surroundings once the slopes are grassed over, without becoming a blot on the landscape of our villages.

Whatever the case, before planning the work, there are a number of aspects and data to be taken into consideration.

Preliminary data needed

To start with, all essential technical information must be procured in order to be able to assess the feasibility of the project, such as:

- geological testing of the area on which the wall is planned to be built

- topographical surveys

- meaningful cross-sectional drawings showing the current condition

- geometry of the planned wall (face angle, height, division into tiers, slope on top)

- external loads applied to the structure (top loads in the event it needs to accommodate a car park or a road)

- what earthquake risk zone the area is in

- geotechnical properties (angle of shearing resistance, cohesion and density) of the earth behind the future wall, of the foundation soil, and of the backfill

- whether there are perched aquifers or seepage of a different nature.

At this point, the next step is to check design calculations using specific software.

Checking design calculations

Checking is performed to assess both internal and external stability. The following tests are carried out in the former case:

- reinforcement strength test, which assesses possible failure mechanisms and determines the spacing, length and tensile strength of the geosynthetics due to be laid

- pull-out test to check that the reinforcement applied does not break or slide out

- direct sliding test, to ensure there is no translational movement across the installation planes

- wrap-around test, to ensure that the length wrapped around the top of each individual layer is stable.

The checks to be carried out during the project’s execution to assess external stability consist in sliding, overturning, bearing capacity and global failure analysis.

Do you want to chat with one of our experts to find the solution that best suits your requirements?

We have 30 years of experience in the industry and can give you access to materials and solutions offering specific performance. Contact us!

Do you want to learn more about the full TeMa Geo Solutions product range for reinforced earth structures? Click here.