TeMa South Africa and Naue collaborate to serve South Africa and project-related sub-Saharan Africa

TeMa South Africa has been appointed as the official representative of Naue in South Africa and for project-related opportunities in sub-Saharan Africa.

This partnership builds on an existing relationship between TeMa and Naue in the Italian market.

The products commercialized prior to this new agreement were mainly regarding TeMa Geo and its environmental field of application, but are now expanding with a larger range of products.

For more information, please reach out to:

Darryn Meisel Managing Director TeMa SA and Nicolas Lewarne Business Development TeMa SA (see their contacts on page 3) or through our websites!

Read or download the full press release: TeMa South Africa collaborates with NAUE

Hotels and acoustic comfort

Acoustic well-being is a must in hotels.

In the competitive hospitality industry, guest satisfaction hinges on details—especially peace and quiet. Yet, hotels, resorts, and high-traffic spaces often grapple with noise complaints: clattering footsteps in hallways, chair scrapes in dining areas, and echoes in lobbies. These disturbances don’t just irritate guests—they damage reviews and repeat business.

From luxury suites to banquet halls, noise transfer is a pervasive challenge:

- Impact noise: Footsteps, dropped items, and moving furniture transmit vibrations through floors.

- Airborne noise: Conversations, music, and HVAC systems travel through walls and floors.

- Regulatory pressures: Many EU countries enforce strict noise regulations.

In Italy, for example, speaking of acoustic comfort and governing its implementation is Prime Ministerial Decree of 5/12/97, which establishes the limit values, calculation methods and requirements to be achieved in order to reduce exposure to excessive noise.

Traditional solutions like thick carpets or floating floors often fall short, compromising aesthetics and are source of problems from a health and hygiene point of view.

A solution for footfall noise that does not require intervention on the screed.

T-Silence offers excellent acoustic insulation performance and can be applied under any finish, including wood, PVC, ceramic tiles and stone, without damaging the existing screed.

For under-tile applications T-Silence dB17, membrane roll consisting of a polymeric sheet bonded on one side to a resilient polypropylene non-woven fabric, and on the other side to a spunbonded fabric, is designed to be installed on a screed under the tiles and then covered with cementitious glue and the desired tiles or wood.

T-Silence absorbs up to 17 dB of noise in just 2,5 mm (0.1 in).

Why hotels choose it

- Aesthetic Flexibility: install under tiles, wood, or stone without altering design plans.

- Space-Saving: thin profile preserves ceiling height—critical for renovations.

- Durability: waterproof and mold-resistant, ideal for bathrooms, spas, and pool areas.

- Quick Installation: pre-rolled sheets adhere directly to screed or flooring, cutting labor time

Conclusion: the sound of success

In an era where silence is a premium commodity, soundproofing membranes like T-Silence DB-17 offer hotels a competitive edge. By merging acoustic performance with design freedom, they turn noise-prone spaces into oases of calm—ensuring guests remember their stay for the right reasons.

‘Natural’ solutions for dry slopes with TeMa products

Environment, climate, energy, territorial planning, natural risk prevention, and water resource research and management are what researchers and planners have to deal with today in connection with environmental works. These are all ‘watchwords’ in the modern world of geotechnics, which require specific know-how and the use of suitable materials, in the awareness that the search for solutions is constantly evolving. With a proactive approach that provides geotechnical applications for soil protection, and expertise to aid the sustainable management of processes, we can now carry out the required works while making the land safe and harmonising the landscape.

Surface water shapes the soil, now more than ever before, due to the increase in extreme events. Today, there is a growing awareness that the ‘natural’ resources we have at our disposal are capable of limiting the effects of scouring and runoff. On dry slopes, for example, soil erosion is the process whereby materials are removed by the mechanical and chemical actions of wind and water. From a technical/scientific perspective, a further distinction is made: in addition to the concept of soil erosion , there is soil loss and sediment yield .

The effect of weathering on the soil is therefore a phenomenon to be foreseen and controlled. On the surface, the causes cannot always be detected, but a Geologist – after carrying out the necessary research – will pinpoint the problems and recommend solutions.

The main phenomena associated with soil depletion are:

- the thickness of arable soil, which includes organic substances, water, mineral salts and fine particles, decreases on a local scale: within a few generations, fertile soil can become arid;

- accelerated and uncontrolled surface erosion can cause landslides on steep slopes, increasing the extent and intensity of crumbling to the point of destroying the vegetation cover of an entire slope;

- eroded material is carried downhill, thereby reducing the capacity of watercourses and thus increasing the risk of flooding;

- the sedimentation of eroded material that ends up in irrigation channels decreases their efficiency and service life;

- eroded material, often laden with chemicals from agricultural practices such as fertilisers and insecticides, instead of being absorbed by the soil, becomes concentrated in watercourses, spreading pollution over a wider area.

The new design concept – determined by precise environmental choices – undoubtedly promotes sustainability. In this respect, on dry slopes, soil ‘helped’ by suitable products to encourage revegetation becomes a very strong ‘barrier’ to inclement weather over time.

By observing the grassed embankments bordering major road and railway routes, we can appreciate the need, which is met, to protect the safety of infrastructures against problems of topsoil slippage. These are artificial embankments, created to meet technical requirements. They were therefore barren at the time of construction, and hence exposed to the impact and removal of soil by rainwater. Ensuring grassing therefore increases the level of safety, improves visual impact and, last but not least, respects biological diversity that is preserved.

New TeMa Geo Solutions materials make these solutions possible. To encourage vegetation to take root, TeMa has come up with K-Mat synthetic geomats and biomats in natural fibre matting (straw, coconut and jute), ECOVERMAT and ECOVERNET, in addition to the X-Grid PET-C AMrange of geomats, which are also useful for reinforcing slopes.

TeMa, an Italian company established in 1993, has gained experience on 4 continents with products for the world of geotechnics, which are trusted by planners and contractors. Over 30 years of providing geotechnical solutions that aid the soil with its own erosion control and stabilisation potential, resulting in a clear environmental advantage.

- Published in Dry slopes, Erosion mats, GEO

Ground reinforcement and stabilization with TeMa geogrids as part of foundation groundworks

Foundation base reinforcement for the construction of rigid reinforced concrete structures on unstable areas: a challenge for engineers across the globe. Sure enough, designers find themselves having to contend with the risk of differential foundation settlement, which can result in cracks in the structure. This means any unsound material in the area often has to be dug out and carted off site, while the layers have to be built up again using materials brought in specially, which can sometimes be expensive. The foundation bed must provide the required bearing capacity and, above all, must eliminate the risk of differential settlement.

The Katlehong job, in South Africa, was a major project for TeMa in a highly critical construction context, given that it involved building a municipal water reservoir in the shape of a 200 thousand hectolitre tank.

With the introduction of a number of geosynthetic products in place of conventional building materials, the costs came in significantly lower than initially projected and structural efficiency was improved considerably across such a large project, promising to deliver a long service life.

The TeMa solution in cases like these: laying X-Grid PET-C-0 100/100 Biax — a biaxial stabilization geogrid woven from high-strength polyester, with a protective polymer coating — over the whole bed in alternating layers with fill material between. With each new layer, the geogrid has to be placed with the appropriate orientation to ensure the structure’s foundation will provide the required overall stability and bearing capacity, thus allowing for and negating the negative effects of any differential settlement.

The use of TeMa Geo geogrids allows for space to be incorporated into the design to accommodate the underground services associated with the structure being built, while providing the designer with significant advantages, compared to the use of conventional natural materials, including ease of installation and shorter construction timeframes.

TeMa, laser focus on the future for 30 (+1) years

TeMa Technologies and Materials has just celebrated thirty years in business. A spin-off of Tegola Canadese, it was actually established in 1993 with the aim of expanding its presence into the commercial, civil and geotechnical construction space. Focused on products and systems to protect building foundations from rainwater and groundwater, the company went on to gain impressive international experience, becoming a go-to provider for the making safe of landfills, handling of contaminated sites, and soil reinforcement systems with solutions designed to be increasingly resilient, even in the face of extreme weather events.

TeMa is headquartered in Italy and is present on four continents with facilities in Italy, the US, South Africa, Spain, Turkey, India, Romania and Russia. Our sales are projected to reach the 100 million euros mark, demonstrating significant growth, doubling our 2021 revenues. A 100% increase within the space of just four years.

Rapidity, speed and reliability are the cornerstones of our relationship with the market, qualities that are paired with innovation, development of human resources and a strong environmental commitment. This sense of environmental responsibility is linked to the fact that our main manufacturing facility is located in an industrial area in Vittorio Veneto set between the unspoilt forests of the Cansiglio plateau and the hills recognized as a UNESCO World Heritage site. A heartfelt respect for the region that we’ve proudly professed from day one of our industrial journey.

This is why, for TeMa, sustainability is about much more than just green claims: we recover quality plastics through two recycling plants for the reuse of polypropylene and high-density polyethylene, one in Russia and one in Romania. All waste materials are sorted and put through grinding, washing and filtering cycles, before being extruded and used to make new products.

Over our 30 (+1) years in business, TeMa has risen to the sustainability challenge with a growing awareness of the importance of this issue, coming up with environmentally friendly solutions for geotechnical applications. One notable example is our range of products for the construction of “reinforced soil retaining walls”, in addition to our specialist area: the development of innovative and effective materials for use in embankments, road ditches, hillside terracing, landfills and contaminated sites. TeMa earth-retaining systems use the actual soil in place of traditional reinforced concrete products, encouraging vegetation growth and being undeniably better for the landscape. Our solutions include geonets, geomembranes and metal structures featuring different angles, designed to support the soil on their own and control rainwater. Many applications include the use of pre-seeded biodegradable matting.

With TeMa products, processes can now be employed that enable a considerable saving in terms of the CO2 emissions involved in handling materials. The resulting reduction in environmental impact is amazing! By doing away with the need for gravel and instead using the soil excavated on site, the energy used to transport materials is kept to a minimum. This approach means structures can be built to be impact resistant, withstanding even violent weather events, which there has certainly been no shortage of in recent years.

TeMa stands as a bastion of modernity in the industry, forever trying out competitive technologies — in our laboratories — in order to come up with simple and efficient materials, products and systems. These solutions are underpinned by research, experimentation and testing: a team of professionals — men and women, engineers and technicians — who all bring their individual area of expertise to the table and are driven by a commitment to customer outcomes, offering support, assistance and an attentive ear.

While ESG (Environmental, Social, Governance) factors are only now becoming mainstream among many businesses, these issues have always been at the very core of TeMa’s corporate philosophy. TeMa products have helped save thousands of loads of aggregate from being quarried and transported over the last thirty-plus years, which has had an extremely positive impact on the environment.

- Published in CORPORATION, Research and development, TeMa Technologies and Materials

Why TeMa?

TeMa Technologies and Materials is a brand operating in 80 countries worldwide with a business network and specialised distributors. An extensive sales network, regional agencies and a technical sales department are supported by an efficient customer service and functional logistics. But the most distinctive characteristic of TeMa, recognised internationally, is its strong drive for innovation.

A permanent feature is the innovative aspect of its products, solutions and processes, as well as its participatory research, reflected in organised meetings, technical seminars and international partnerships.

A solid technical sales organisation

We see the 30-year milestone that we have just celebrated with our collaborators as a start-up towards the future. With our training and experience in technical and sales areas, and the support of our distributor network, we can further enhance our ability to offer tailor-made solutions to all customers.

Indeed, our strong ties with the international market and highly skilled professionals encourages our technicians to make continuous improvements. Our business model sets us apart, making the products and services we offer unrivalled.

We also greatly value the development of ideas that takes place by exchanging experiences during training courses for our in-house employees and advanced courses in skills and competences for our external collaborators. This highly customer-centred business model aims to meet their needs while guiding decisions with solutions adapted to each situation.

TeMa constantly pursues certified quality

In our R&D department, we design and test new solutions and technologies to provide our customers with innovative products. Along with experimentation, this has enabled us to achieve several international patents.

We carry out daily tests regarding durability, compressive strength and drainage capacity in the most critical cases to ensure that our products deliver the expected properties. Each product placed on the market must comply with the stringent quality standards stipulated.

It is in this relentless verification of excellence that TeMa has implemented a UNI EN ISO 9001-certified quality system, documenting top performance across the whole production process. In compliance with the CPD (Construction Product Directive) 89/106/EEC, the product ranges TeMa offers have followed the procedure to be awarded the CE mark.

We monitor and optimise all aspects of the work and provide various services:

- Testing on raw materials.

- Inspection of finished products and prototypes for quality and performance.

- Compilation and updating of product Safety Data sheets.

- Quality control.

- Production process supervision and control.

- Sample testing of production lots and compliance checks.

Consultancy and technical support.

Our in-house technical department is on hand to assist customers, from choosing the solution through to its implementation, for any type of application.

Our technicians provide support for the sales network and assist customers in choosing the most appropriate products to solve each specific technical problem and meet specification requirements. This is achieved by analysing all relevant variables and providing complete and comprehensive technical specifications and installation methods.

Any upcoming projects? Contact us! We can help you choose the most effective solution.

- Published in CORPORATION, Research and development

TeMa Geo Solutions: geotechnical solutions

The TeMa Geo Solutions division has developed considerable experience in geotechnical applications and developed technologies and products, thereby ensuring that designers can meet increasingly strict regulations concerning the environment and the landscape.

These applications are for the protection, maintenance, retention, reinforcement and drainage in the field of major environmental projects, involving products that provide innovative efficient and long-lasting solutions.

We are aware that a kind of public resistance to sustainability announcements has already begun. We are therefore interested in helping companies that are taking appropriate action to protect the environment. This is not only to ensure that they can better comply with regulations but also, and above all, to increase the effectiveness and credibility of their work.

TeMa Geo solutions in applications

The areas of expertise of TeMa Geo Solutions include:

- football fields

- landfills and contaminated sites

- tunnels

- reinforced soil retaining structures

- dry slopes

- grassy road and railway embankments

- roads

- drainage ditches

- horse training and racing tracks.

Products and functions: a range starting with geosynthetics

Geogrids are structural elements used to reinforce soils in the construction of retaining walls, block retaining walls, reinforced soil retaining structures, landfills and contaminated sites. The open mesh structure allows the reinforcement geogrids to develop ‘passive’ resistance at the transverse ribs, thus effectively increasing their inherent stabilising effect and enabling the system to withstand significant levels of stress.

The TeMa Geo Solutions range includes uniaxial or biaxial X-Grid geogrids made of fibreglass, polyester or PET coated with a polymer layer, coupled, or not, with a nonwoven geotextile, to be chosen to suit the project.

Offering products such as bentonite geocomposites, drainage geocomposites, facings, erosion control mats and essential accessories, the TeMa Geo Solutions range fulfils various functions for the retention anddrainage of rainwater and groundwater.

The TeMa Geo world offers its long-standing (since 1993) expertise and experience in the polymer-based product category (geosynthetics). Over the years, research at its in-house labs has enabled the development of solutions that integrate with the environment in a more specific sense, such as biodegradable erosion control mats, and in a broader sense, such as geomats and studded membranes.

TeMa also offers cutting-edge geotechnical solutions for vineyards

This is not surprising, as the TeMa Geo headquarters are situated on the eastern edge of the Prosecco hills, a UNESCO World Heritage Site. The company therefore has made its experience available to preserve and protect the viticultural landscape with its products for erosion control, reinforcement and ground drainage in an environment subject to the passage of agricultural vehicles. Click here to download the specific catalogue.

Damp, rising damp and efflorescence in basements.

Damp, mould, stains and flaky plaster in basements are a homeowner’s worst nightmare. We’ve mentioned numerous times that weather events and groundwater, where not controlled properly, are the main cause of damp. Of course, it doesn’t just affect the walls, but the whole structure, including flooring, on the basement level or even on the ground floor.

The phenomenon that’s so often underestimated is so-called “rising damp”, which occurs when water under the ground enters walls as a result of direct contact and is pushed upwards by capillary action, allowing the moisture to rise around ten centimetres or more. The moisture can even climb metres up the wall by “latching on” to molecules of a different kind, in this case those of the actual walls. The damage caused by the abnormal increase in moisture inside walls is immediately visible on the walls of ground-floor rooms or basements.

What effects the water’s capillary action has

The effect of capillary absorption manifests in the form of:

- static damage to the building, which is weakened and becomes less safe

- worsening occupant comfort as a result of unhealthy, smelly rooms

- cosmetic damage, with the appearance of stains and peeling plaster

- higher heating costs due to the lower surface temperatures of internal walls

- efflorescence

- a capillary action that causes water to rise through walls, bringing with it salts from the ground that, once they crystallize as a result of the evaporation process, swell and cause paint and plaster to peel: white stains forming around cracks are known as salt efflorescence.

The effects are less visible when the surface affected is flooring, with symptoms like swelling, salt efflorescence, mould or changes in the colour of grout often only appearing later on.

All these issues derive from the misguided choice of materials, or poorly designed and executed work, often compounded by the fact that the foundations’ waterproofing is damaged or even non-existent. This is not an issue linked to weather events, rather it stems from the presence of groundwater.

How TeMa Building Solutions can help

Both rising damp and efflorescence issues can be prevented with the use of suitable materials. TeMa Building Solutions offers an extensive range of studded membranes and drainage geocomposites to remove water before it comes into contact with the structure and to provide waterproofing with reliable, lasting protection.

Our engineers are here to help you choose the right specific product for your next project.

Contact us!

- Published in BUILDING, Drainage geocomposites, Foundation and underground structures, Foundation and underground structures - Damp proofing systems, Foundation and underground structures - Drainage systems, Foundation and underground structures - Systems for mechanical protection, Foundation and underground structures - Systems for Waterproofing

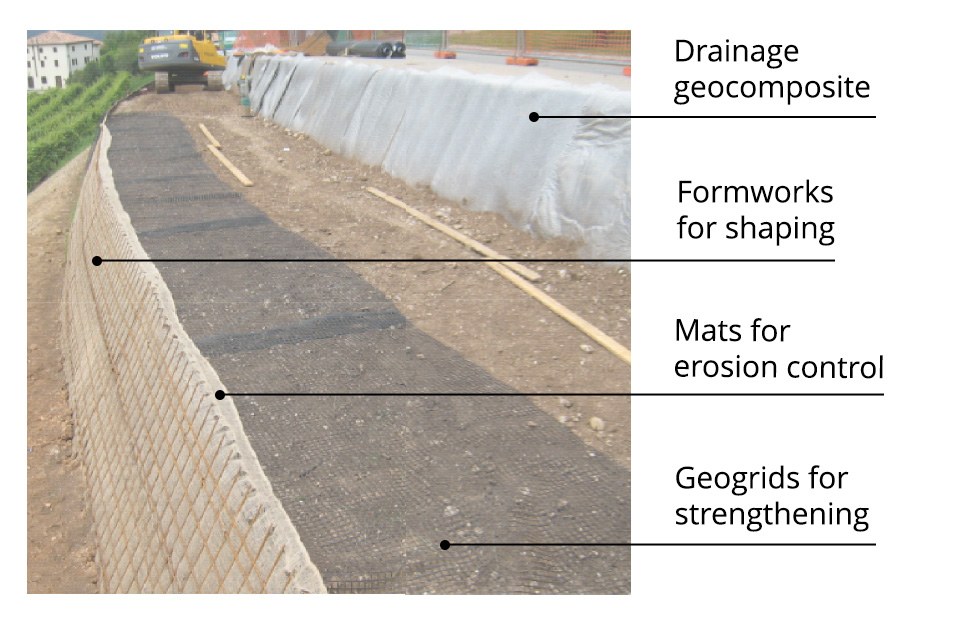

System for reinforced soil retaining structures

T-System is the system from TeMa Geo Solutions that includes various components for strengthening, surface erosion control, drainage and retaining used in the construction of reinforced soil retaining structures: innovation that we’ve been exploring here at TeMa since our inception 30 years ago, and that is now one of our hallmarks. Let’s take a more detailed look below.

Components for strengthening

Designed for strengthening, the knitted X-Grid PET C geogrids are made from high-strength polyester yarn, with a protective polymer coating. They deliver tensile strength in the 20 kN/m to 800 kN/m range.

Components for erosion control

They protect the face of the structure from erosive agents, like wind and driving rain, until the vegetation has had time to establish. TeMa Geo Solutions offers natural solutions made from cellulose fibres, like Ecovermat, or jute fibres, like Ecovernet, as well as synthetic solutions made from monofilaments (K-Mat F), polypropylene (K-Mat FA) or fibreglass (K-Mat FG Green).

Components for drainage

Drainage geocomposites like Q-Drain are used to address the problem of water seeping into the backfill.

Components for retaining

We have a line of facings made from electrically welded wire mesh — with inclinations ranging from 65° to 80° — to ensure the exposed face is straight.

Practical tips

On site

System components must be stored well away from machinery, and suitably protected from dust or residues from work on site.

To avoid excessive overlaps and waste, the X-Grid geogrids must be cut to size using a suitable metal stand with metal trestles supporting a circular rod to be inserted inside the roll.

Erosion control components — whether biodegradable or synthetic — must be stored in a dry place and not in direct contact with the natural ground, so as to avoid laying problems later on.

Metal formwork must be stored well away from areas where machinery is operating, and carried in only when it is time to install.

During assembly, it is best to apply U-shaped strips of rubber or metal so that the geogrids can be wrapped correctly over the formwork without getting caught on the top of the bars. (see photo)

Special instructions

We advise against backfilling with silty and clayey material; at the very least, only use this kind of material after mixing it with aggregate.

The full range of system components comes with instructions on the relevant procedures to be followed. Contact us, we’ll be happy to provide case studies and full information.

Solutions for protecting foundations and below-grade walls

The health of walls in contact with the soil — like foundations and below-grade walls — is the primary concern of the home’s occupants, especially where underground garages or basements are involved: any sign of damp or mould is evidence of damage that can have serious financial consequences in these areas of the building. And restoring the interior to good health is not always feasible.

The risks lie both in the foundations — namely in the horizontal structures that receive and absorb the loads of the whole building — and in the below-grade walls, namely the vertical structures that have to withstand considerable loads. If we take the worsening weather patterns of recent years and add in pesky capillary rising damp, and groundwater pressure, there’s clearly a need to ensure the products used provide improved performance.

How do we best protect foundations and below-grade walls?

The way to keep underground rooms healthy is to use specific, tried-and-tested products, applied correctly as per the technical literature. TeMa Building Solutions has various solutions on offer.

Bentonite geocomposites

Bentonite geocomposites can be used to ensure the concrete is properly waterproofed. Comprising natural sodium bentonite, they self-bond to concrete (if used as waterproofing prior to insitu casting) and are suitable for both vertical applications (below-grade walls) and horizontal applications (slab foundations).

Studded membranes

Studded membranes are one of the most widely used products given their dual function:

- they mechanically protect waterproofing: they prevent damage to the waterproofing layer during the backfilling and compaction process at the construction phase, and protect from the subsequent micro-movements as the soil settles, and the considerable loads that the walls have to withstand

- they serve as damp-proofing: they stop moisture, which — even in the absence of hydrostatic pressure — can undermine the structure and cause patches of mould to appear on internal walls.

Drainage geocomposites

They reduce hydrostatic pressure exerted on vertical walls, conveying water away from the walls to the outer perimeter. They are laminated with one or two nonwovens serving as a filter layer, stopping the system becoming clogged. The TeMa Building Solutions range includes geonets, studded membranes and monofilament structure.

Need help choosing the right product? Contact us! Our experts are here to help you any way they can.